Mounting screw connection type cavity filter

A cavity filter and mounting screw technology, which is applied to waveguide devices, electrical components, circuits, etc., can solve problems such as low production efficiency, inconsistent filter performance, and unreasonable filter structure design, so as to improve production efficiency, Shorten the processing process and ensure the effect of product size/shape tolerance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

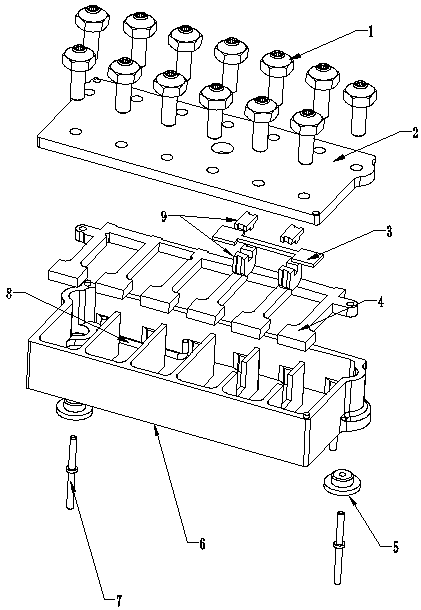

[0042] As shown in the figure, the specific implementation method is as follows:

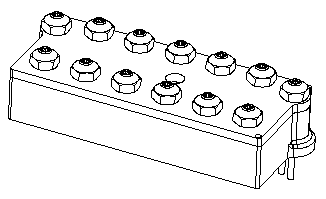

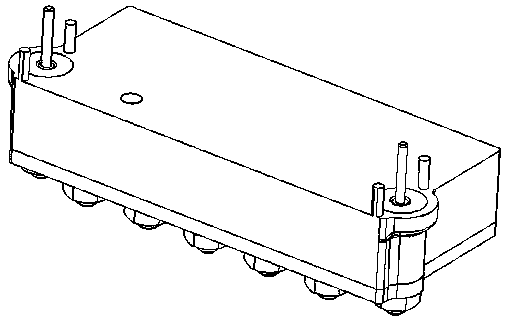

[0043] A screw-connected cavity filter, including a die-cast cavity 60 with one end open and a sealing cover 20, a number of weight-reducing grooves 6001 are processed on the outer wall of the cavity 60, and six intervals are fixed on the sealing cover 20 The resonant plate 40 set and connected to each other, the resonant plate 40 and the sealing cover plate 20 are integrally formed by die-casting, the inner cavity of the cavity 60 is divided into six interconnected resonant cavities by radial bars, one of the outer walls of the cavity There are two rows of thirteen adjustment screws 1 for adjusting filter parameters, and the thirteen adjustment screws 1 are divided into six frequency adjustment screws located at the end of the resonator plate and seven bandwidth adjustment screws located at the end of the resonator plate close to the sealing cover One end of the adjustment screw 1 penetrates th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com