Preparation method of shale rock fragment sample for micron indentation experiment

A technology for sample preparation and indentation experiment, applied in the field of petroleum exploration, can solve the problems of difficult logging in shale horizontal wells, rarely obtain mechanical parameters, and difficult to apply effectively, saving manpower and material resources, reducing costs, and easy operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

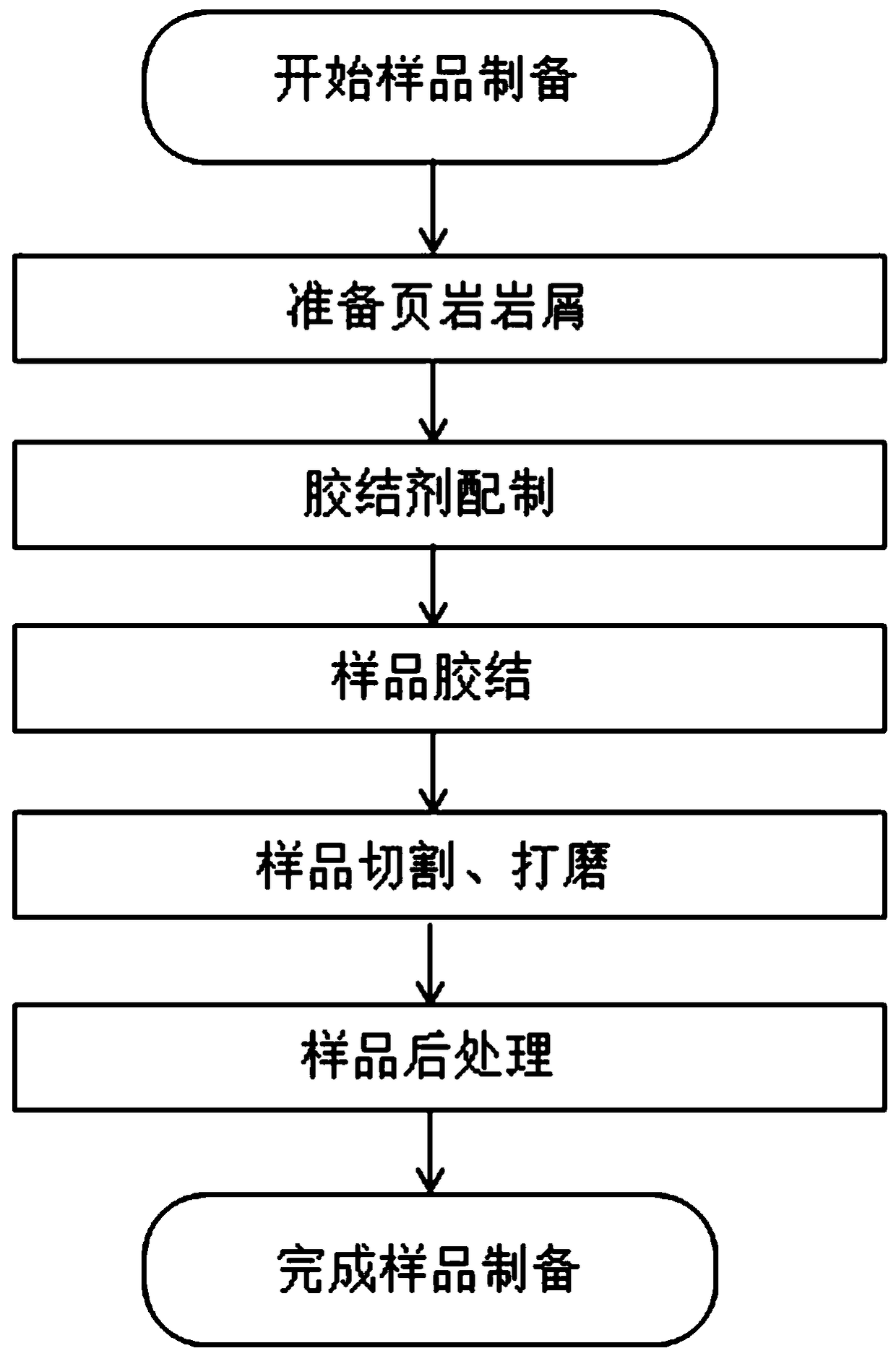

[0039] A method for preparing a shale cuttings sample for a micron indentation experiment, a method for preparing a shale cuttings sample for a micron indentation experiment, comprising the following steps:

[0040] S1, prepare epoxy resin binder, the mass ratio of binder is:

[0041] Base material 40~60 parts

[0042] Curing agent 20 parts

[0043] Thinner 3~6 parts;

[0044] S2, sample cementation, including the following sub-steps:

[0045] Prepare a cylindrical rubber mold for pouring shale cuttings, and pour the prepared cement into the mold;

[0046] Put the screened semi-finished cuttings into the prepared mold filled with cement, so that it is just completely covered by the cement;

[0047] Put the mold with built-in cement and semi-finished cuttings into a vacuu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com