Method for enhancing whiteness of sulphoaluminate clinker

A technology of sulfoaluminate clinker and whiteness, which is applied in the field of cement clinker, can solve the problems of high calcination temperature, alkali return of products, long demoulding time with low early strength and low strength, etc., and achieves the effect of high strength and improved whiteness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

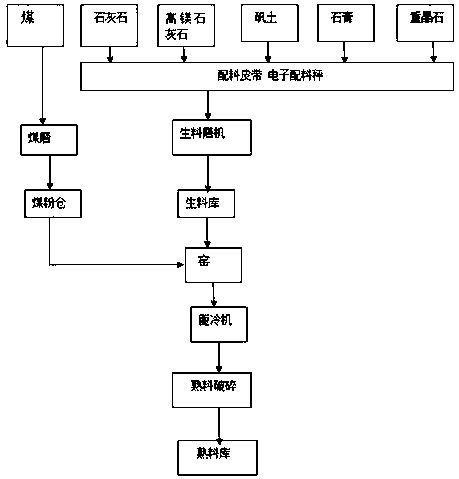

[0040] This embodiment provides a method for improving the whiteness of sulphoaluminate clinker, including raw material selection, raw meal grinding and clinker calcination; raw materials selection bauxite, gypsum, limestone, high magnesium limestone, dolomite and barite stone.

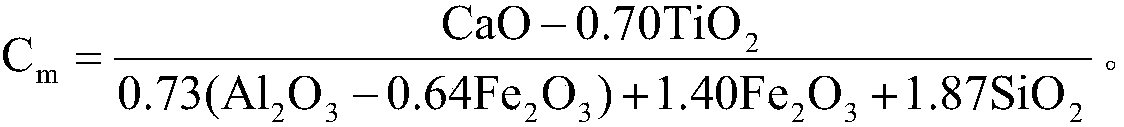

[0041] Raw meal ingredients make the clinker obtained after the raw meal is calcined in the kiln meet the following conditions: a. The basicity coefficient Cm is 0.92-1.0, and the sulfur-aluminum ratio P≤3.82; b. The MgO content in the clinker is 1-2.5%. BaSO 4 Content > 0.1% and 2 o 3 content <1.2%; after the raw material is batched, the raw material is ground, and the fineness of the raw material is controlled by a 0.08mm square hole sieve to less than 12%; then it is put into the kiln for clinker calcination, and the calciner temperature is 870°C ± 10°C. Calcination is carried out at a band forming temperature of 1280°C to 1340°C to obtain white sulphoaluminate clinker with a whiteness ≥ 80.

Embodiment 2

[0043] This embodiment provides a method for improving the whiteness of sulphoaluminate clinker, including raw material selection, raw meal grinding and clinker calcination; raw materials selection bauxite, gypsum, limestone, high magnesium limestone, dolomite and barite stone.

[0044] Raw meal ingredients make the clinker obtained after the raw meal is calcined in the kiln meet the following conditions: a. The ratio of clinker is controlled to meet the basicity coefficient Cm of 0.92-1.0, and the sulfur-aluminum ratio P≤3.82; b. MgO in the clinker The content is 1~2.5%, BaSO 4 Content > 0.1% and 2 o 3 content <1.2%; after the raw material is batched, the raw material is ground, and the fineness of the raw material is controlled by a 0.08mm square hole sieve to less than 12%; then it is put into the kiln for clinker calcination, and the calciner temperature is 870°C ± 10°C. Calcination is carried out at a band forming temperature of 1280°C to 1340°C to obtain white sulphoal...

Embodiment 3

[0053] This example discloses a method for improving the whiteness of sulphoaluminate clinker.

[0054] Select the following ingredients for ingredients:

[0055] Bauxite: 37.72%;

[0056] Gypsum: 14.85%;

[0057] Limestone: 45.45%;

[0058] High magnesium limestone: 0;

[0059] Dolomite: 0.99%;

[0060] Barite: 0.99%.

[0061] After the raw material is mixed, the raw material is ground, and the fineness of the raw material is controlled to be less than 12% through a 0.08mm square hole sieve; then it is put into the kiln for clinker calcination, and the calciner is calcined at a temperature of 870°C and a firing zone temperature of 1290°C. , to obtain a white sulfoaluminate clinker with a whiteness of 82.

[0062] The clinker of the present embodiment has an alkalinity coefficient Cm of 0.92, a sulfur-aluminum ratio P of 3.81; free gypsum of 0.26%; Fe 2 o 3 content of 1.00%, MgO content of 1.50%, BaSO 4 The content is 1.20%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com