A kind of waste water treatment process of spray paint room

A technology for wastewater treatment and paint spraying room, which is applied in water/sewage treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. The effect of rapid contact oxidation, reducing secondary pollution problems and improving reaction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

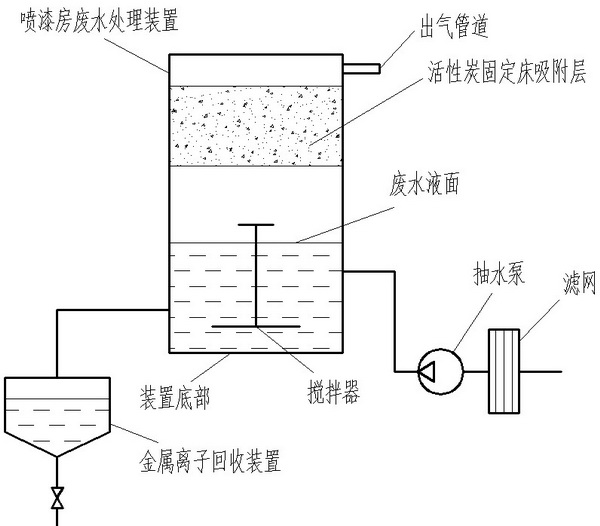

[0039] 1) The wastewater in the spray booth is filtered by the filter and then pumped into the wastewater treatment device in the spray booth, and then catalyst and H are added to the wastewater treatment device in the spray booth. 2 o 2 And fully stirred and reacted for 0.5 hours, all the liquid after the reaction was discharged into the metal ion recovery device containing slaked lime water, and discharged after static precipitation in the metal ion recovery device for 2 hours, after the above process, the waste water from the spray booth was treated. At the same time, the solid deposit in the metal ion recovery device after the liquid is discharged is regenerated.

[0040] 2) In the above-mentioned step 1), the catalyst added in the waste water treatment device of the spray booth is CuSO 4 ·5H 2 O and MgSO 4 ·7H 2 O.

[0041] 3) In the above-mentioned steps 1), the H 2 o 2 , and its content is 0.015% (mass percentage).

[0042] 4) In the above-mentioned step 1), the...

no. 2 example

[0053] 1) The wastewater in the spray booth is filtered by the filter and then pumped into the wastewater treatment device in the spray booth, and then catalyst and H are added to the wastewater treatment device in the spray booth. 2 o 2 And fully stirred and reacted for 0.75 hours, all the liquid after the reaction was discharged into the metal ion recovery device containing slaked lime water, and discharged after static precipitation in the metal ion recovery device for 2.5 hours, after the above process, the waste water from the spray booth was treated. At the same time, the solid deposit in the metal ion recovery device after the liquid is discharged is regenerated.

[0054] 2) In the above-mentioned step 1), the catalyst added in the waste water treatment device of the spray booth is CuSO 4 ·5H 2 O and MgSO 4 ·7H 2 O.

[0055] 3) In the above-mentioned steps 1), the H 2 o 2 , and its content is 0.03% (mass percentage).

[0056] 4) In the above-mentioned step 1), t...

no. 3 example

[0067] 1) The wastewater in the spray booth is filtered by the filter and then pumped into the wastewater treatment device in the spray booth, and then catalyst and H are added to the wastewater treatment device in the spray booth. 2 o 2 And fully stirred and reacted for 1 hour, all the liquid after the reaction was discharged into the metal ion recovery device containing slaked lime water, and discharged after static precipitation in the metal ion recovery device for 3 hours, after the above process, the waste water from the spray booth was treated. At the same time, the solid deposit in the metal ion recovery device after the liquid is discharged is regenerated.

[0068] 2) In the above-mentioned step 1), the catalyst added in the waste water treatment device of the spray booth is CuSO 4 ·5H 2 O and MgSO 4 ·7H 2 O.

[0069] 3) In the above-mentioned steps 1), the H 2 o 2 , and its content is 0.045% (mass percentage).

[0070] 4) In the above-mentioned step 1), the Cu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com