Frame-type car body rear compartment structure and welding method

A welding method and frame-type technology, applied in the superstructure, welding equipment, auxiliary welding equipment, etc., can solve the problems of the quality of the welding seam and the large deformation of the structure size in the rear cabin of the car body, so as to prevent the risk of welding seam burn through and improve production. Efficiency and product qualification rate, the effect of reducing welding deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

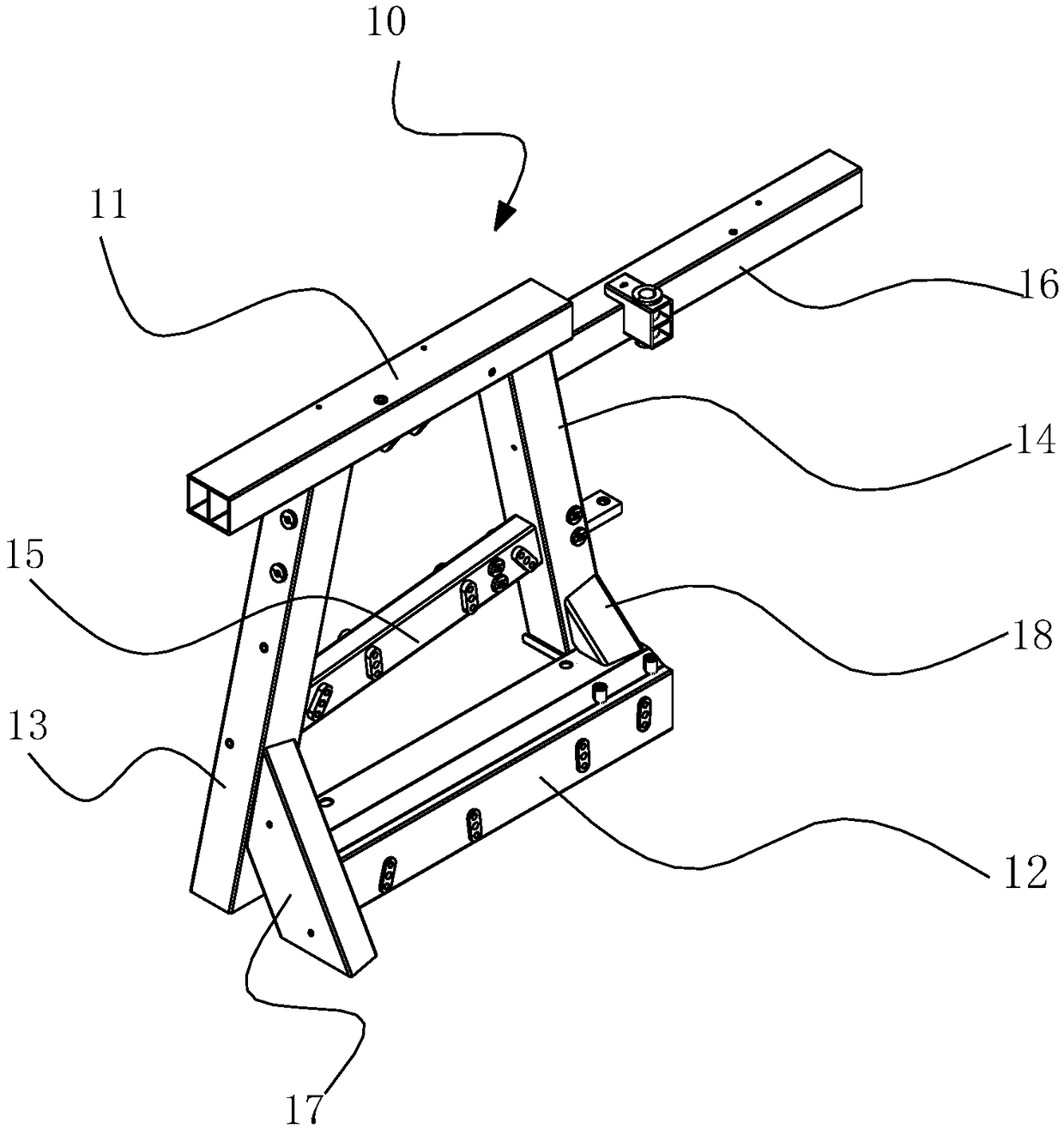

[0028] Such as figure 1 and figure 2 As shown, the present embodiment provides a frame type car body rear cabin structure, including the first side assembly 10 of the rear part of the vehicle body, the second side assembly 20 of the rear part of the vehicle body, the first beam assembly 30 of the rear part, the second rear part assembly Crossbeam assembly 40, battery box frame auxiliary fixing beam 50, battery crossbeam 60 and process beam 70, wherein the two ends of the rear first crossbeam assembly 30 are respectively installed with the first side assembly 10 and the rear part of the vehicle body. The second side assembly 20 at the rear of the vehicle body, the top of the first side assembly 10 at the rear of the vehicle body and the top end of the second side assembly 20 at the rear of the vehicle body are connected through the second rear beam assembly 40 The battery box frame auxiliary fixing beam 50 , the battery beam 60 , and the process beam 70 are also installed bet...

Embodiment 2

[0034] This embodiment provides a welding method for a frame-type vehicle body rear compartment structure. Welding the frame-type vehicle body rear compartment structure described in Embodiment 1 includes the following steps: Step S1: the rear first beam assembly 30, the vehicle body rear The first side assembly 10, the second rear beam assembly 40, the battery beam 60, the second side assembly 20 at the rear of the vehicle body, and the auxiliary fixing beam 50 of the battery box frame are sequentially positioned and clamped on the first tooling; steps S2: Weld the first rear beam assembly 30, the second rear beam assembly 40, the battery box frame auxiliary fixing beam 50, and the battery beam 60 to the rear first side assembly of the vehicle body in sequence. 10 and the second side assembly 20 at the rear of the vehicle body; step S3: at the bottom of the first side assembly 10 at the rear of the vehicle body and at the bottom of the second side assembly 20 at the rear of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com