Powder falling-resistant hydrophobic nano-aerogel heat-insulating sheet as well as preparation method and use method thereof

A nano-aerogel, powder-hydrophobic technology, applied in chemical instruments and methods, applications, household appliances, etc., can solve problems such as unfavorable operation of construction personnel and threat to construction personnel's health, etc. Sexual problems, the effect of low preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

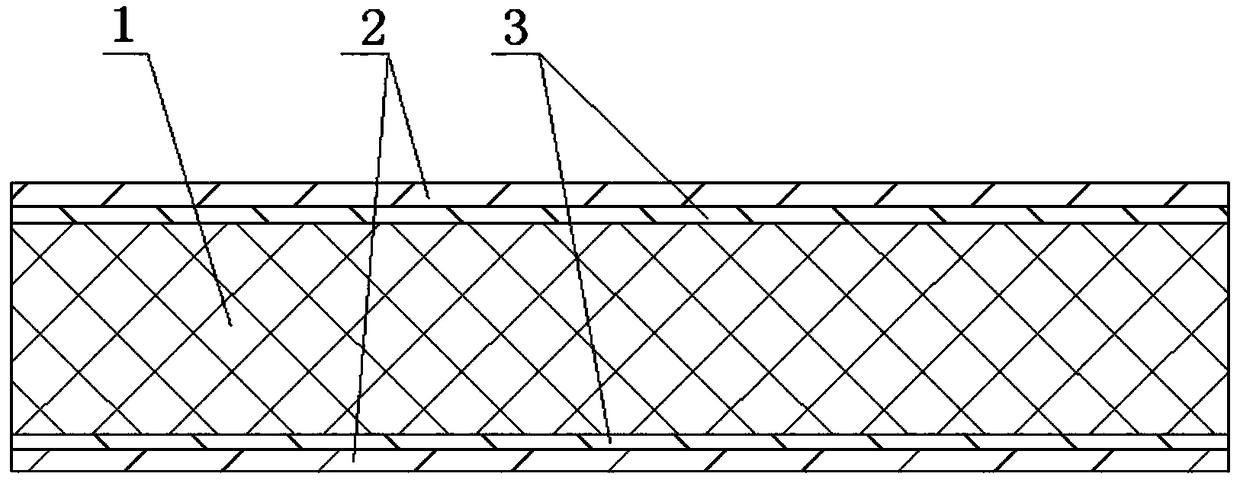

[0029] A kind of preparation method of anti-powder drop hydrophobic nano-airgel thermal insulation sheet of the present invention, the method comprises the following steps:

[0030] 1) Mix and impregnate glass fiber needle felt with sol to obtain sol glass fiber felt precursor; the basic characteristics of the glass fiber needle felt are thickness 3mm, density 90-115kg / m³; thickness 5mm, density 100-120kg / m³ m³; thickness 6mm, density 105~125kg / m³ or thickness 10mm, density 120~135kg / m³; the sol is made of tetraethyl orthosilicate as precursor, 99% industrial methanol, hydrolysis catalyst, additive according to 16: (96 ~128)︰5︰1 volume ratio, uniformly mixed and reacted for 5h.

[0031] 2) Aging and surface modification of the sol glass fiber mat precursor to obtain a sol fiber mat; the aging solution is ethanol or methanol solution, the aging temperature is 50~55°C, and the aging time is ≥40h , the aging agent is an alkylating agent.

[0032] 3) The sol glass fiber mat is s...

Embodiment 1

[0040] Ethyl orthosilicate, 99% industrial methanol, hydrolysis catalyst, and additives were uniformly mixed and reacted for 5 hours according to the volume ratio of 16:128:5:1 to obtain a sol; Mix and impregnate 120~135kg / m³ glass fiber needle mat with sol to obtain sol glass fiber mat precursor. Soak the sol glass fiber mat precursor in ethanol solution at 50~55℃ for 40 hours for aging treatment, then add alkylating agent for surface treatment to obtain sol fiber mat. The sol glass fiber mat was subjected to supercritical CO 2 Drying treatment, drying temperature is 53°C, drying pressure is 14.5MPa, CO 2 The gas flow rate is 2600kg / h, and the drying time is 5.5h to obtain a hydrophobic nano airgel thermal insulation material. The hydrophobic nano-airgel thermal insulation material is processed according to the specifications of length × width × thickness = 1500mm × 600mm × 10mm, and the hydrophobic nano-airgel thermal insulation material with a fixed size is obtained. The...

Embodiment 2

[0042] Ethyl orthosilicate, 99% industrial methanol, hydrolysis catalyst, and additives were uniformly mixed and reacted for 5 hours according to the volume ratio of 16:112:5:1 to obtain a sol; the length was 61300mm, the width was 1500mm, and the thickness was 3mm. Mix and impregnate 90~115kg / m³ glass fiber needle mat with sol to obtain sol glass fiber mat precursor. Soak the sol glass fiber mat precursor in ethanol solution at 50-55°C for 40h for aging treatment, and then add an alkylating agent for surface modification to obtain the sol fiber mat. The sol glass fiber mat was subjected to supercritical CO 2 Drying treatment, drying temperature is 55°C, drying pressure is 14MPa, CO 2 The gas flow rate is 2500kg / h, the drying time is 3h, and the hydrophobic nano-airgel thermal insulation material is obtained. The hydrophobic nano-airgel thermal insulation material is processed according to the specifications of length × width × thickness = 1500mm × 1200mm × 3mm, and the hydr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com