A method for manufacturing seamless steel pipes for long-pipe trailer gas cylinders

A technology for seamless steel pipes and manufacturing methods, applied in the field of manufacturing large-diameter seamless steel pipes, capable of solving problems such as uneven wall thickness, poor quality of the inner and outer surfaces of steel pipes, and low wall thickness precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to facilitate understanding of the present invention, the present invention enumerates the following examples. It should be clear to those skilled in the art that the embodiments are only for helping to understand the present invention, and should not be regarded as specific limitations on the present invention.

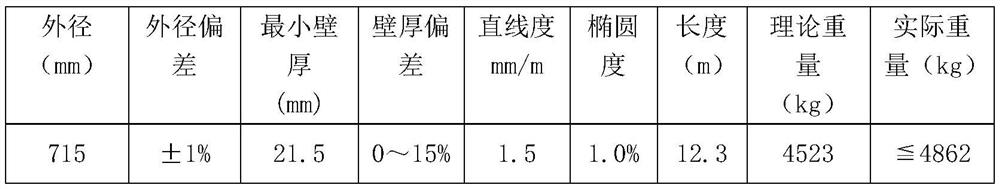

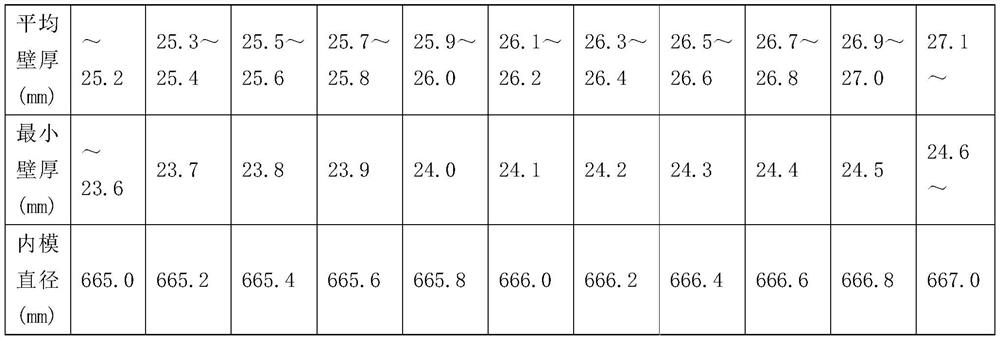

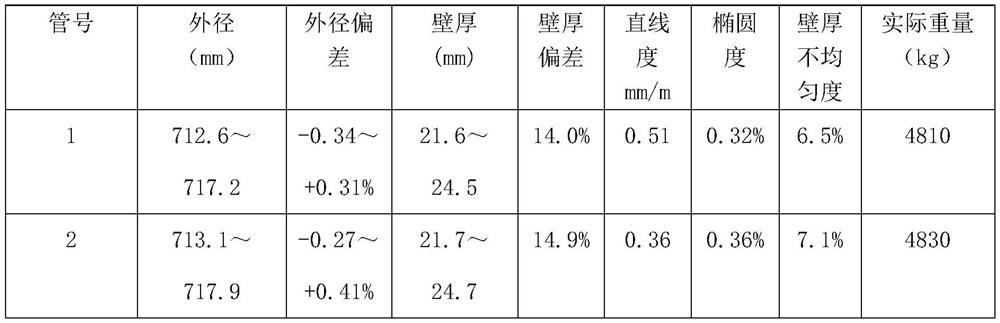

[0041] In this embodiment, a method for manufacturing a seamless steel pipe for a long-tube trailer gas cylinder, the product specification is: 715x21.5x12300mm seamless steel pipe, the material of the steel pipe is 4130X, and the technical requirements are shown in the following table:

[0042]

[0043] The specific implementation steps are as follows:

[0044] Step a: The continuous casting slab with a diameter of 500 mm and a length of 3500 mm is heated in an annular heating furnace for 610 minutes at a heating temperature of 830°C to 1290°C, and the temperature of the continuous casting slab is 1250°C;

[0045] Step b: piercing the heated cont...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com