Preparation method of waste tyre recycling material with modified surplus sludge

A technology for excess sludge and waste tires, applied in chemical instruments and methods, solid waste removal, transportation and packaging, etc., can solve problems such as secondary pollution, achieve strong hydrophilicity, widen application scope, and biocompatibility good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

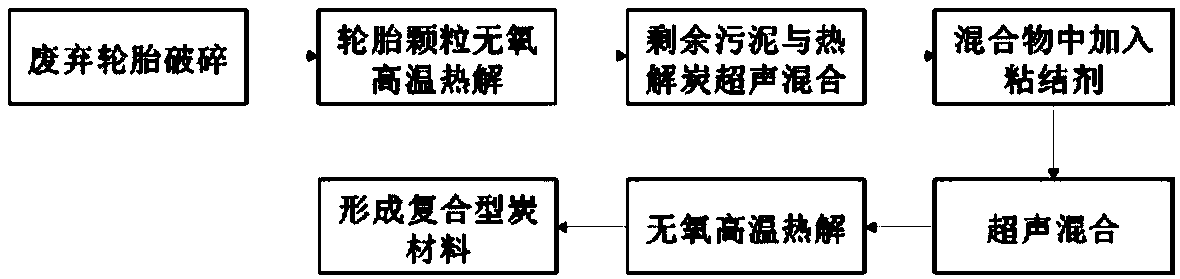

Method used

Image

Examples

Embodiment 1

[0025] Take 10g of waste rubber tires, crush and grind to form particles with a particle size of 1mm, and the tire particles are in N 2 Under the atmosphere, pyrolyze waste tires at 300°C for 2 hours to form waste tire pyrolytic carbon particles. Take 100g of residual sludge with a concentration of 10g / L and pyrolytic carbon particles for 40Hz ultrasonic mixing. The mixing time is 10h. After mixing, add 150g concentration 0.05g / L methyl cellulose, and then 50Hz ultrasonic mixing, mixing time is 1h. After that, the pyrolytic carbon with the remaining sludge adhered to the N 2 After pyrolysis at 400°C for 10 h in the atmosphere, the waste tire carbon material improved by excess sludge was finally prepared. The prepared carbon material is used for bio-filming. Taking ordinary waste tire pyrolysis carbon as a control, the bio-filming performance of waste tire carbon material improved by excess sludge is shown in the table below.

[0026] material name

Embodiment 2

[0028] Take 20g of waste rubber tires, crush and grind to form particles with a particle size of 0.5cm, and the tire particles are in N 2 Under the atmosphere, pyrolyze waste tires at 600°C for 5 hours to form pyrolytic carbon particles. Take 100g of residual sludge with a concentration of 5g / L and pyrolytic carbon particles for 70Hz ultrasonic mixing. The mixing time is 6h. After mixing, add 200g concentration 0.5g / L hydroxyethyl cellulose, and then 95Hz ultrasonic mixing, mixing time is 12h. After that, the pyrolytic carbon with the remaining sludge adhered to the N 2 Pyrolysis at 700°C for 7 hours in the atmosphere, finally prepared the waste tire carbon material modified by excess sludge. The prepared carbon material is used as an electrode material, and the ordinary waste tire pyrolysis carbon is used as a comparison. The electrochemical performance of the waste tire carbon material improved by excess sludge is shown in the following table.

[0029] material na...

Embodiment 3

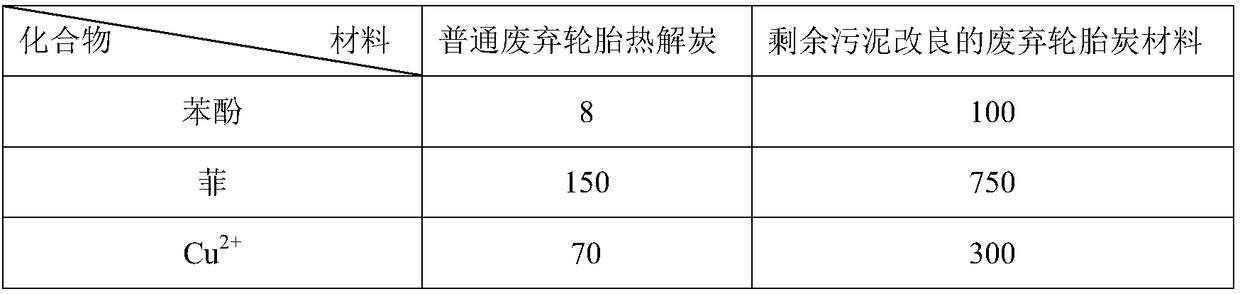

[0031] Take 50g of waste rubber tires, crush and grind them to form particles with a particle size of 1cm. The tire particles are pyrolyzed at 1000°C for 10h in an Ar atmosphere to form waste tire pyrolysis carbon particles. Take 50g of excess sludge with a concentration of 0.1g / L Perform 100Hz ultrasonic mixing with pyrolytic carbon particles for 2 hours. After mixing, add 100 g of polyoxyethylene with a concentration of 1.0 g / L, and then perform 75 Hz ultrasonic mixing for 24 hours. After that, the pyrolytic carbon with the remaining sludge adhered to the N 2 After pyrolysis at 1000°C for 4 hours in the atmosphere, the waste tire carbon material modified with excess sludge was finally prepared. The prepared carbon material was used as an adsorption material, and ordinary waste tire pyrolytic carbon was used as a control, and phenol, phenanthrene, Cu 2+ As the adsorption object, the adsorption performance of waste tire carbon materials improved by excess sludge is shown in t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com