Downhole vibrating screening machine

A vibrating screen and separator technology, applied in the direction of filter screen, solid separation, grille, etc., can solve the problems of inapplicability, large floor space, high energy consumption, improve production efficiency, facilitate storage and use, and realize automation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The following content describes the specific implementation manner of the present invention in detail in conjunction with the accompanying drawings.

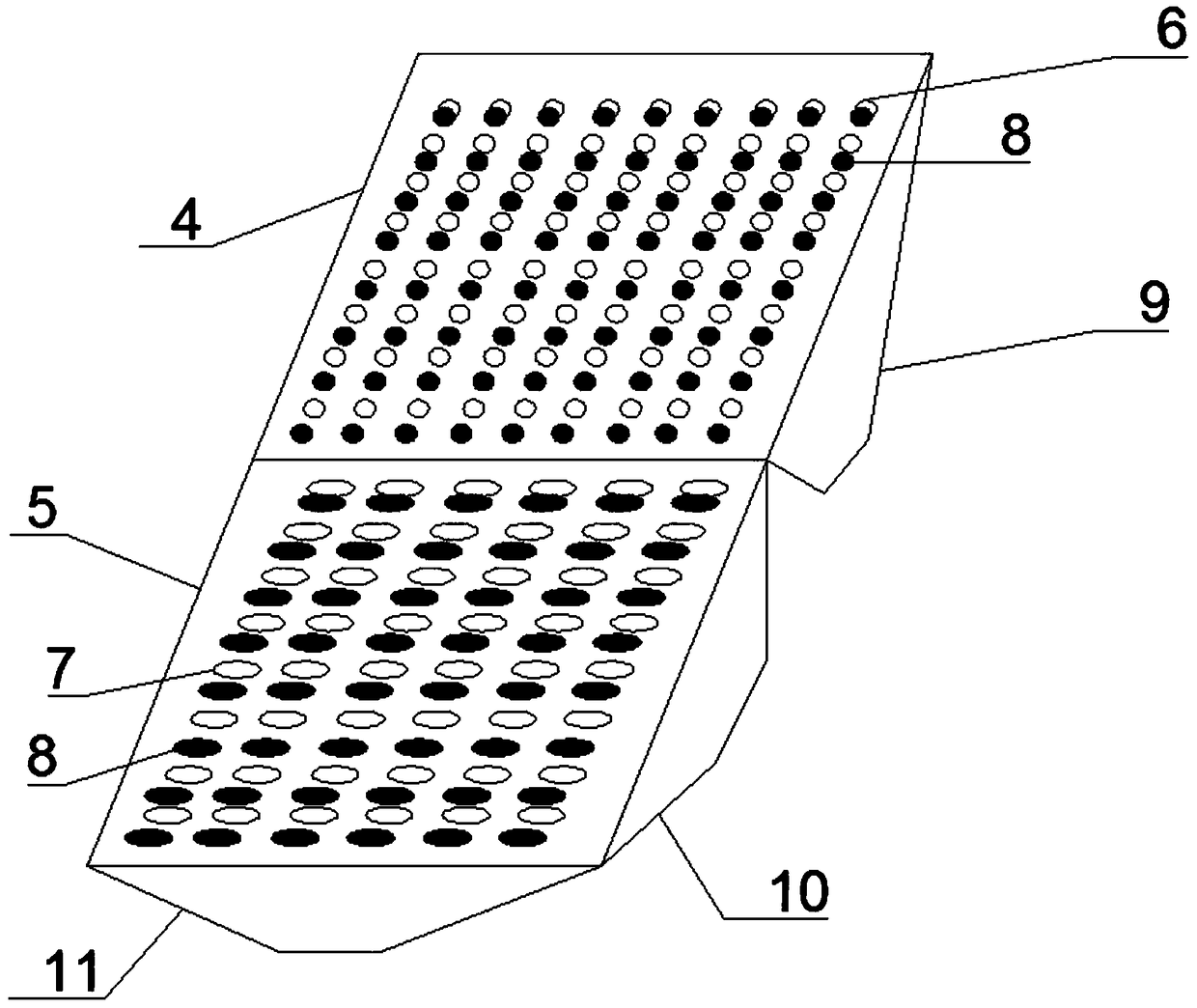

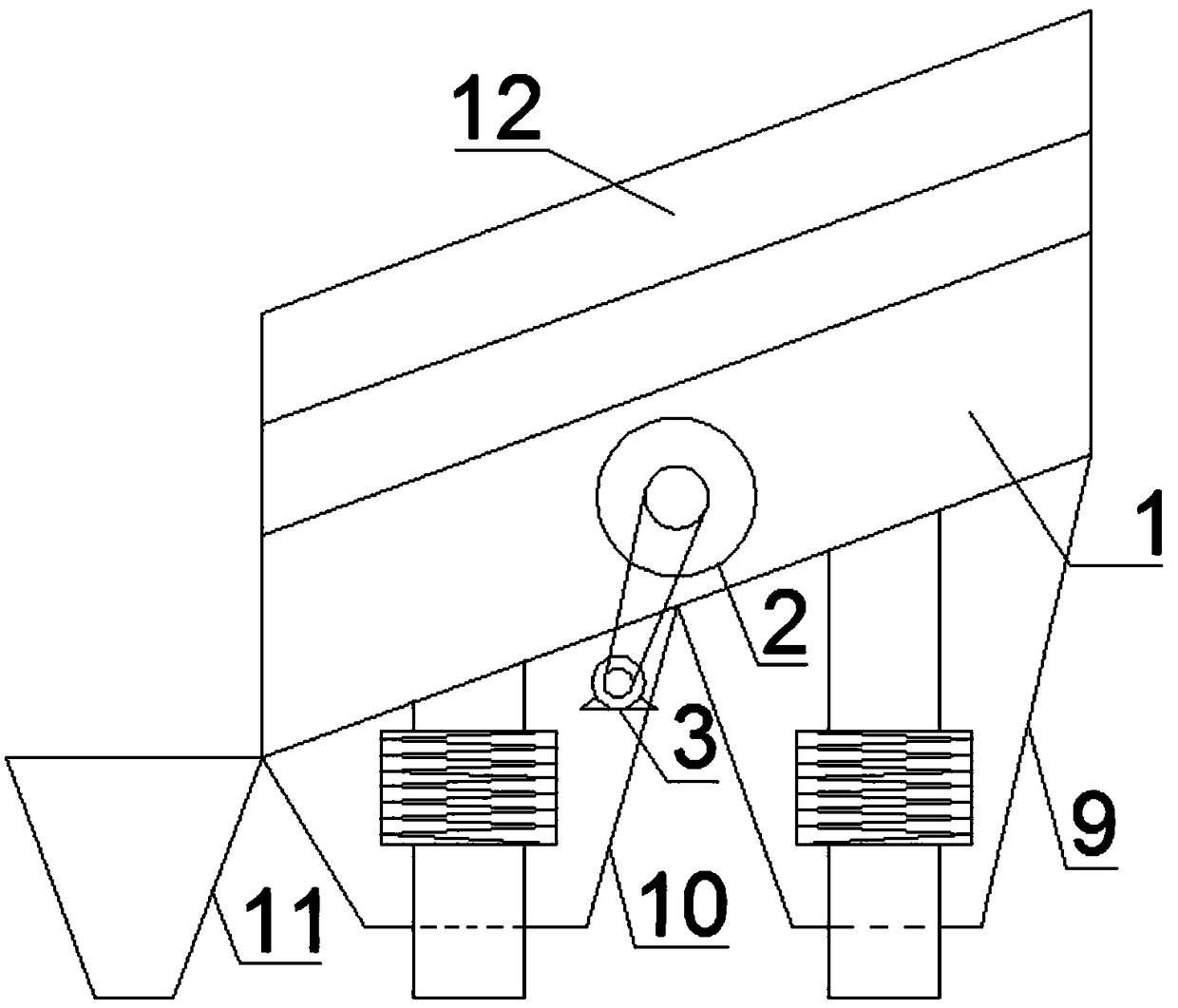

[0019] Refer to attached figure 1 And attached figure 2 , a downhole vibrating screening machine, comprising a frame 1, a vibrator 2 and a servo motor 3, the frame 1 is provided with a primary screen body 4 and a secondary screen body 5 slidingly connected with the primary screen body 4, the The first-level sieve body 4 and the second-level sieve body 5 are inclined. The first-level sieve hole 6 on the first-level sieve body 4 is smaller than the second-level sieve hole 7 on the second-level sieve body 5. The shape of the sieve hole is not limited to a circle. shape, which can be triangular or quadrangular; the bottom of the primary sieve body 4 is connected with a small piece discharge port 9, the bottom of the secondary sieve body 5 is connected with a medium block discharge port 10, and the bottom of the secondary si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com