A kind of pyridine nitrogen enrichment carbon nanotube catalyst and its preparation method and application

A carbon nanotube and pyridine nitrogen technology, which is applied in the field of electrocatalysis, can solve the problems of low percentage of pyridine nitrogen and application limitations, and achieves the effects of good stability, high catalytic performance and good application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] The preparation method of pyridine nitrogen enriched carbon nanotube catalyst comprises the following steps:

[0042] 600mg of 1-10 phenanthroline and 200mg of multi-walled carbon nanotubes were dispersed into a mixed solution of 25ml of ethanol and 25ml of deionized water, stirred at room temperature for 12 hours, then evaporated to dryness at 105°C, and ground in an agate mortar Finally, the precursor of the electrocatalyst was obtained; the electrocatalyst precursor was placed in a porcelain boat, heat-treated in a tube furnace, and the temperature was raised from room temperature to 700°C at 5°C / min, kept for 3 hours, and then cooled at 3.3°C / min to room temperature, the heat treatment atmosphere is an ammonia atmosphere, and the pyridine nitrogen-enriched carbon nanotube catalyst is obtained.

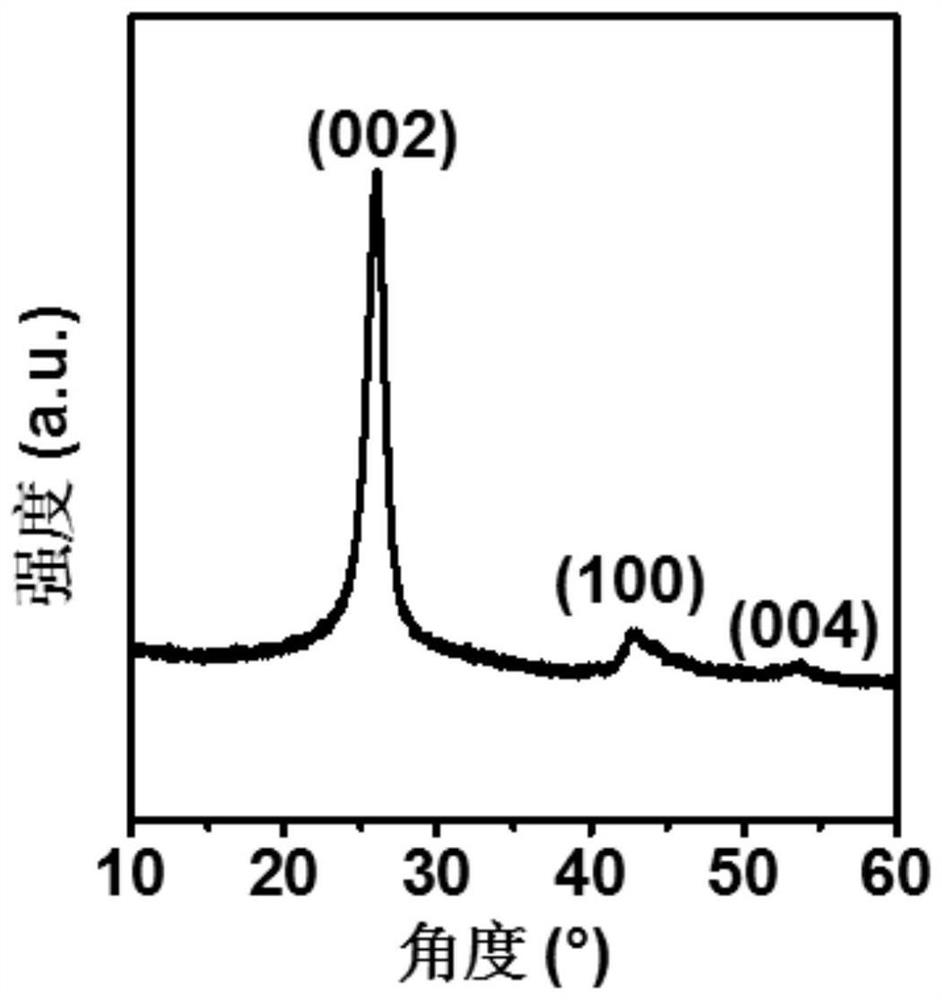

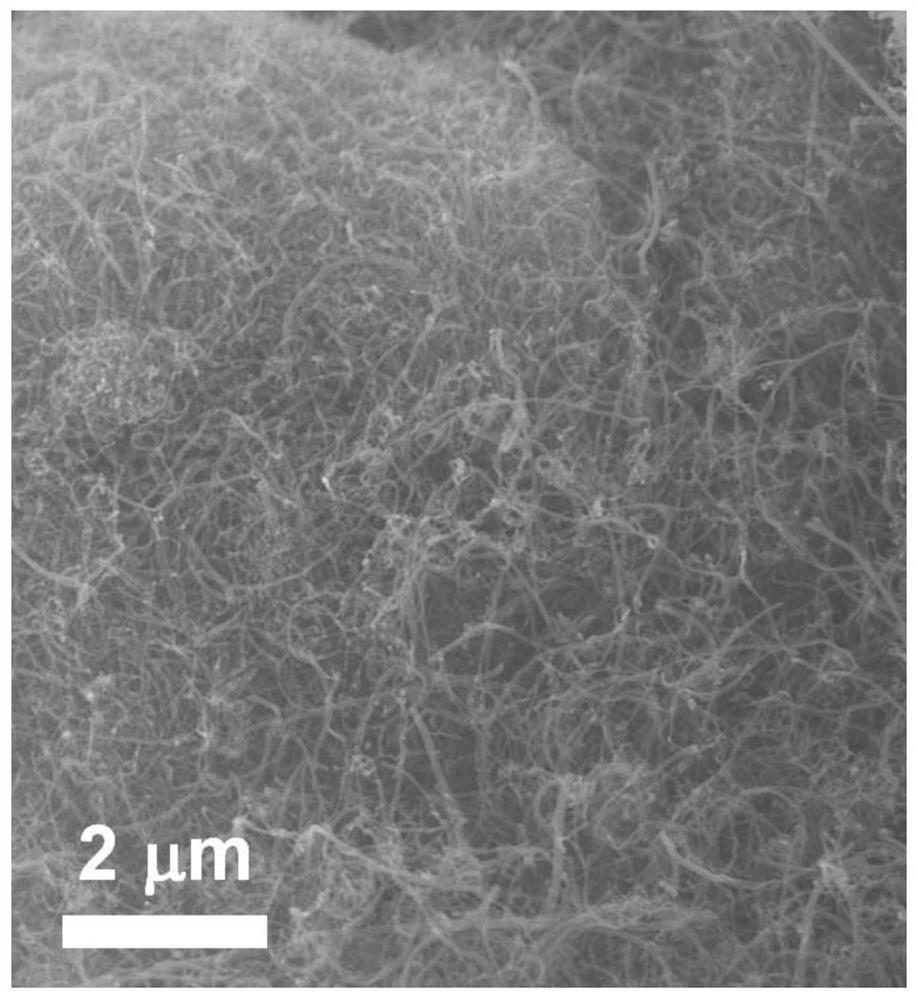

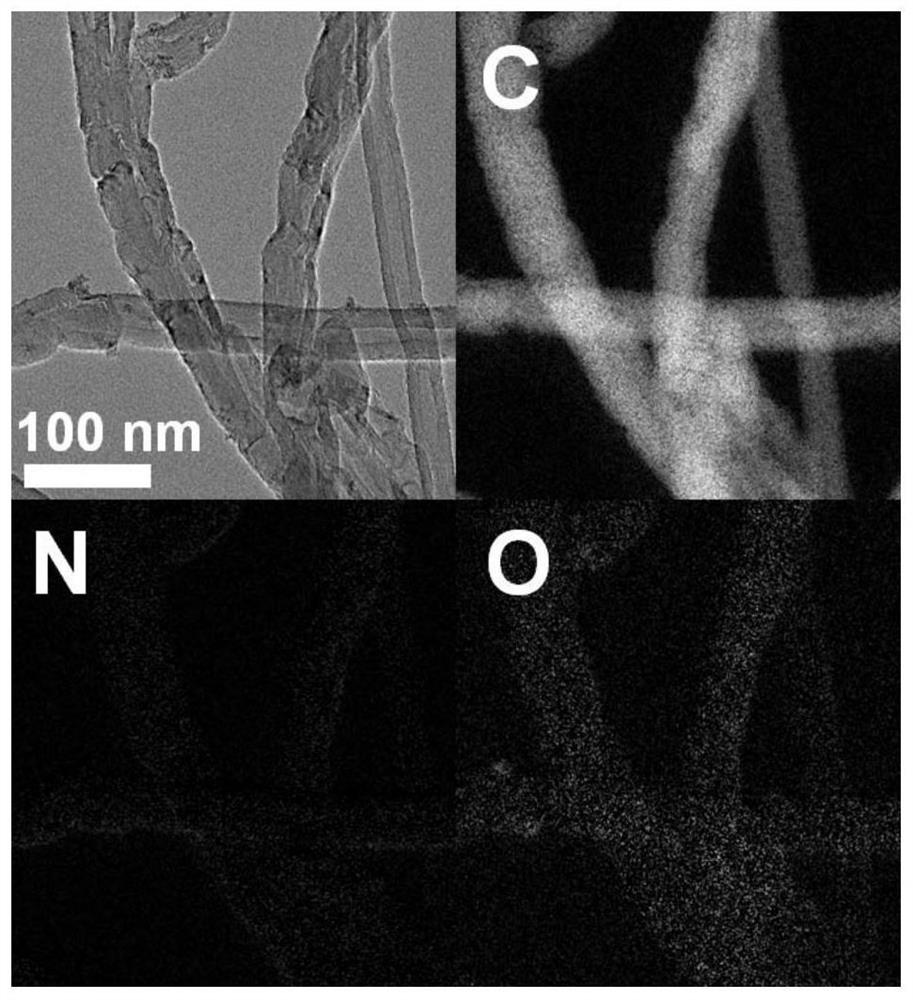

[0043] The X-ray diffraction curve of the catalyst prepared in this embodiment is as follows: figure 1 It can be seen from the figure that the catalyst prepared in this exa...

Embodiment 2

[0054] Repeat Example 1, the difference is that the heat treatment temperature is changed from 700°C to 500°C, the appearance of the obtained electrocatalyst is similar to that obtained in Example 1, but the total nitrogen content is reduced to 2.0%, and the percentage of pyridine nitrogen is 58.7% %.

[0055] The catalyst prepared in this example was prepared in 0.5M NaHCO saturated with carbon dioxide 3 The Faraday efficiency-voltage diagram of carbon monoxide obtained by electrolysis in aqueous solution is as follows Image 6 As shown, the product selectivity of the electrocatalyst obtained is not much different from the electrocatalyst obtained in Example 1.

[0056] The catalyst prepared in this example was prepared in 0.5M NaHCO saturated with carbon dioxide 3 The current density-voltage diagram of carbon monoxide obtained by electrolysis in aqueous solution is as follows Figure 7 shown. The maximum current density of carbon monoxide is 13mA / cm 2 .

Embodiment 3

[0058] Repeat Example 1, the difference is that the heat treatment temperature is changed from 700°C to 300°C, the appearance of the electrocatalyst obtained is similar to the electrocatalyst obtained in Example 1, but the total nitrogen content is reduced to 1.0%, and the percentage of pyridine nitrogen is 79.6%.

[0059] The catalyst prepared in this example was prepared in 0.5M NaHCO saturated with carbon dioxide 3 Faradaic efficiency of carbon monoxide obtained by electrolysis in aqueous solution - voltage as Image 6 shown. The product selectivity of the obtained electrocatalyst is not much different from that of the electrocatalyst obtained in Example 1.

[0060] The catalyst prepared in this example was prepared in 0.5M NaHCO saturated with carbon dioxide 3 The current density-voltage diagram of carbon monoxide obtained by electrolysis in aqueous solution is as follows Figure 7 shown. The maximum current density of carbon monoxide is 8mA / cm 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com