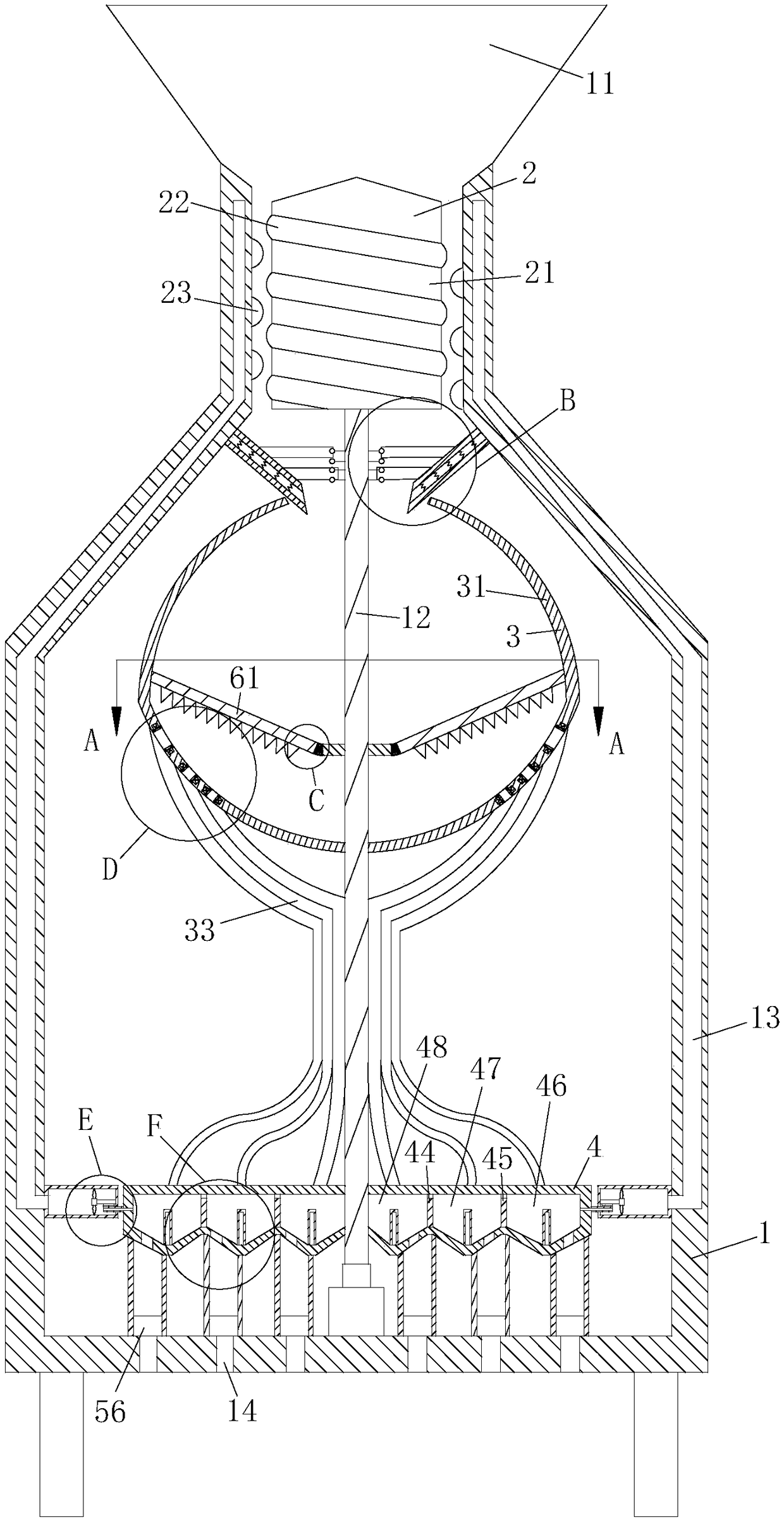

Multifunctional fertilizer pelletizer

A granulator and multi-functional technology, which is applied in dryers, granulation in rotary tanks, heating devices, etc., can solve the problems of different particle sizes and use restrictions, and achieve the improvement of utilization rate and uniform and thorough drying. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0030] As an embodiment of the present invention, the lower surface of the turntable 41 is designed in a "W" shape, and the stirring rods 49 are all located in the depression, and the first discharge ports 55 are all located at the slope; when working, the turntable 41 rotates, and the fertilizer Stirring rod 49 is heated and dried, and the dried fertilizer is discharged from the first outlet 55 by centrifugal force. The "W" shape design on the lower surface of the turntable 41 can make the fertilizer more concentrated and improve the drying efficiency.

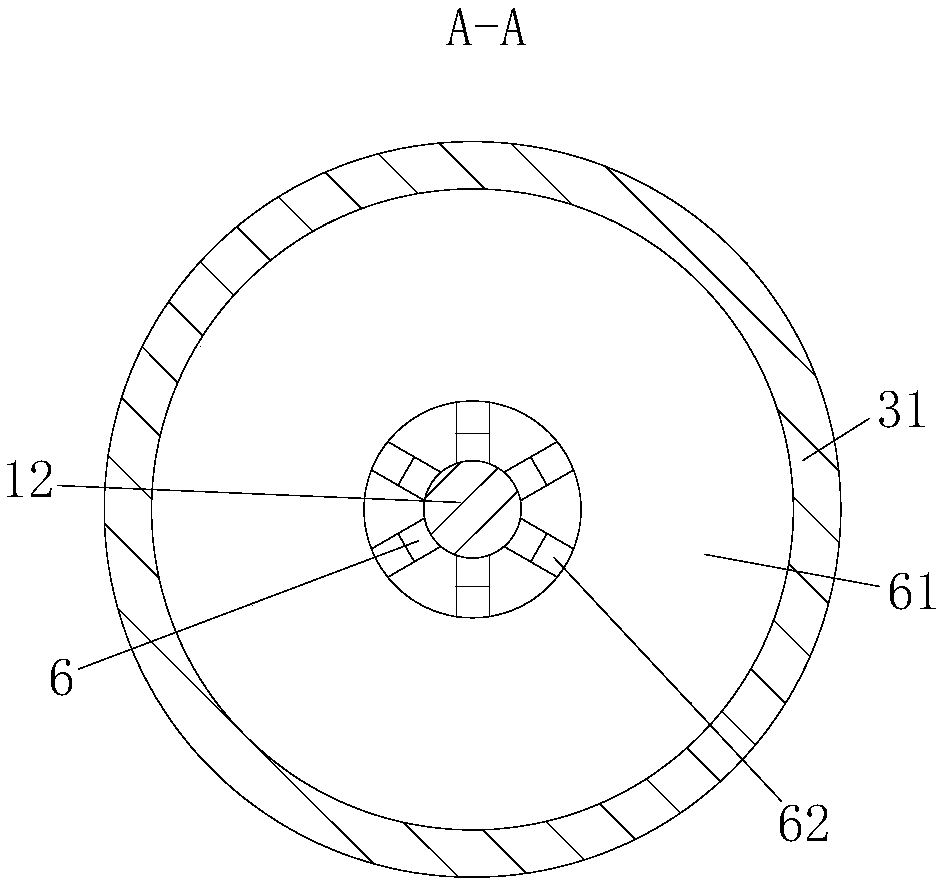

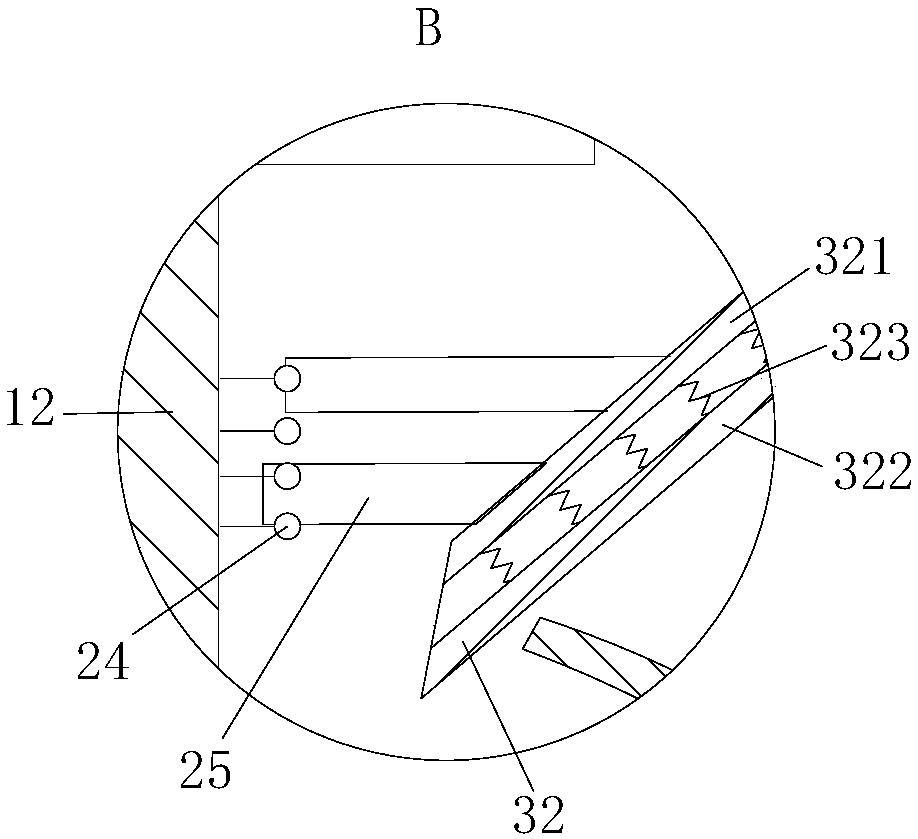

[0031] As an embodiment of the present invention, the surface of the transmission shaft 12 is evenly fixed with a fixed rod 6; the fixed rod 6 is located in the granulation barrel 31; the inner wall of the granulation barrel 31 is slidably connected with a crushing plate 61; The crushing plate 61 is designed to be circular and inclined; the crushing plate 61 is fixedly connected to one end of the fixed rod 6 through a rubber b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com