Waste-gas treating device of waste-plastic recycling system

A waste gas treatment device and regeneration system technology, which is applied in the direction of combined devices, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of polluting the ecological environment, surrounding residents, health and safety hazards, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

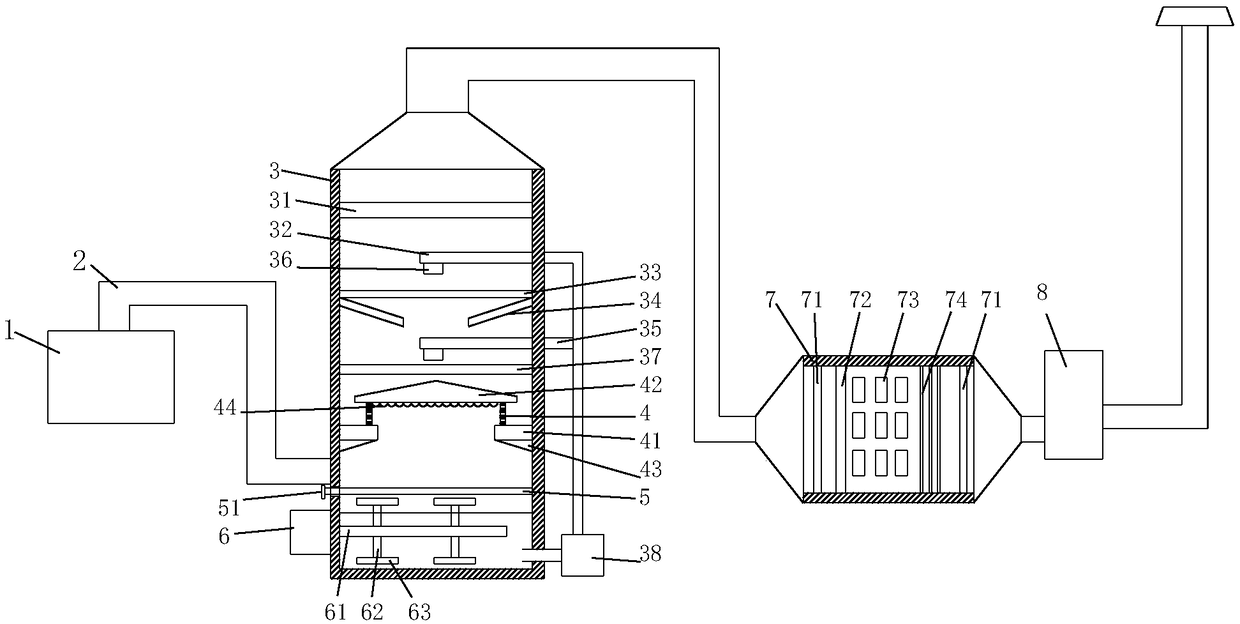

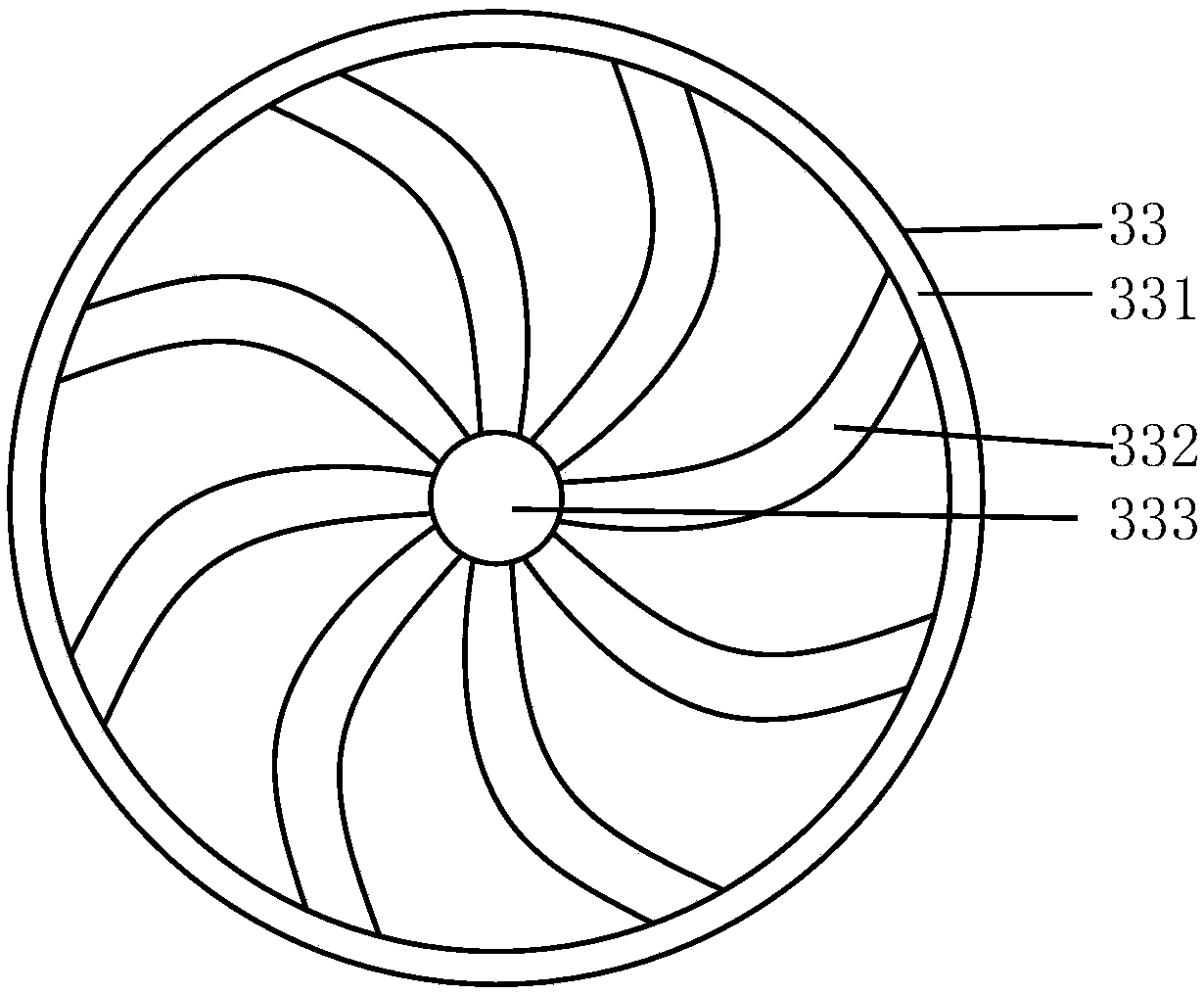

[0025] Such as Figure 1 to Figure 6 As shown, the present invention provides a waste gas treatment device for a waste plastic recycling system, comprising a gas collection hood 1, a purification box 3 and a treatment box 7, the gas collection hood 1 communicates with the bottom side of the purification box 3 through a gas delivery pipe 2,

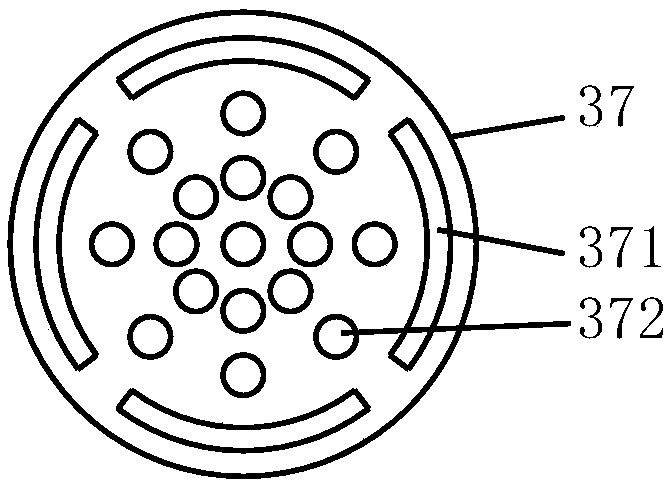

[0026] The inner wall of the purification box 3 is provided with a baffle ring 41 corresponding to the top of the gas delivery pipe 2, and the upper surface of the baffle ring 41 is provided with a flow-limiting pipe 4. The surface of the flow-limiting pipe 4 is uniformly provided with through holes 401, and the top of the flow-limiting pipe 4 is covered with The baffle 42, and the restrictor tube 4 is arranged on the inner side of the baffle 42, the lower surface of the retaining ring 41 is provided with a drain plate 43, and the inner wall of the purification box 3 is fixedly provided with a filter plate 5 below the corresponding drain pl...

Embodiment 2

[0033] Such as Figure 1 to Figure 6 As shown, the present invention provides a waste gas treatment device for a waste plastic recycling system, comprising a gas collection hood 1, a purification box 3 and a treatment box 7, the gas collection hood 1 communicates with the bottom side of the purification box 3 through a gas delivery pipe 2,

[0034] The inner wall of the purification box 3 is provided with a baffle ring 41 corresponding to the top of the gas delivery pipe 2, and the upper surface of the baffle ring 41 is provided with a flow-limiting pipe 4. The surface of the flow-limiting pipe 4 is uniformly provided with through holes 401, and the top of the flow-limiting pipe 4 is covered with The baffle 42, and the restrictor tube 4 is arranged on the inner side of the baffle 42, the lower surface of the retaining ring 41 is provided with a drain plate 43, and the inner wall of the purification box 3 is fixedly provided with a filter plate 5 below the corresponding drain pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com