Safe and environment-friendly gas discharging device for chemical plant equipment or power plant equipment

A kind of factory equipment, safety and environmental protection technology, applied in transportation and packaging, chemical instruments and methods, dispersed particle separation and other directions, can solve the problem of not well solved safety discharge port blockage and other problems, achieve obvious environmental protection noise reduction effect, reliable protection , The effect of reducing the damage of upstream equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

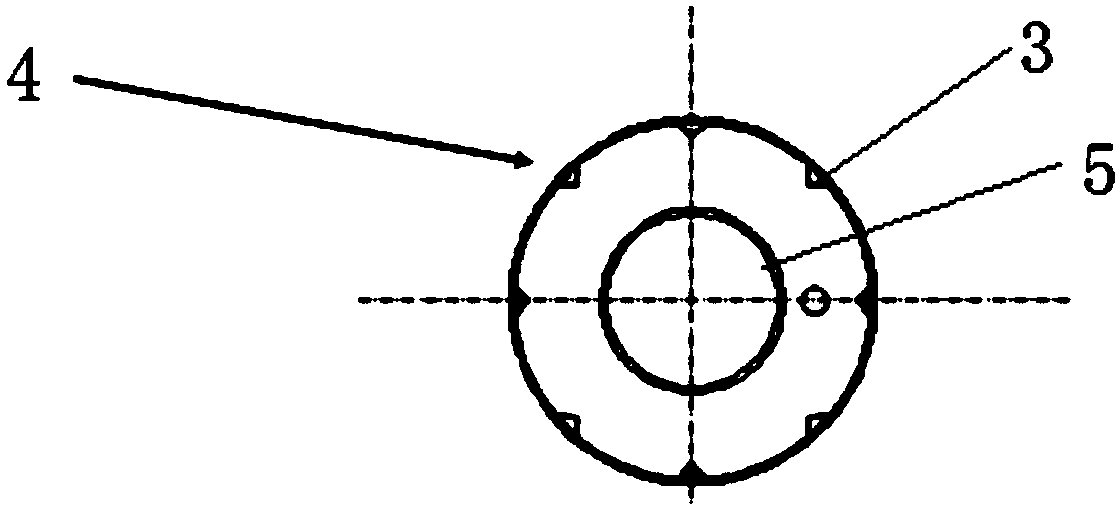

[0035] refer to figure 1 , figure 2 , a gas safety and environmental protection discharge device for chemical plant equipment or power plant equipment, comprising an upper head 1, a lower head 2, a support rod 3, a filter screen 4, a connecting pipe 5, a connecting flange 6 and a drain pipe 7, The upper head 1 and the lower head 2 are arranged separately, and are welded and connected by the support rods 3 uniformly arranged on the circumference, and the filter screen 4 is surrounded by the outer side of the circle surrounded by the support rods 3, and the filter screen 4 and the support rods 3 constitute the upper seal. The cylinder wall between the head 1 and the lower head 2, the upper end of the connecting pipe 5 extends into the lower head 2, and the lower end is connected with the connecting flange 6, and the connecting flange 6 is used to connect to chemical plant equipment or power plant equipment, The drain pipe 7 is obliquely inserted into the lower head 2, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com