Horizontal ballast water filtering device with pleated filter screen

A filter device and ballast water technology, which is applied in the direction of fixed filter elements, filter separation, chemical instruments and methods, etc., can solve the problem that the backwash system has not been effectively solved, the backwash effect is not good, and the filter effect has deteriorated, etc. problem, to achieve the effect of simple and easy operation, shortened running time and satisfactory effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention is described in more detail below in conjunction with accompanying drawing example:

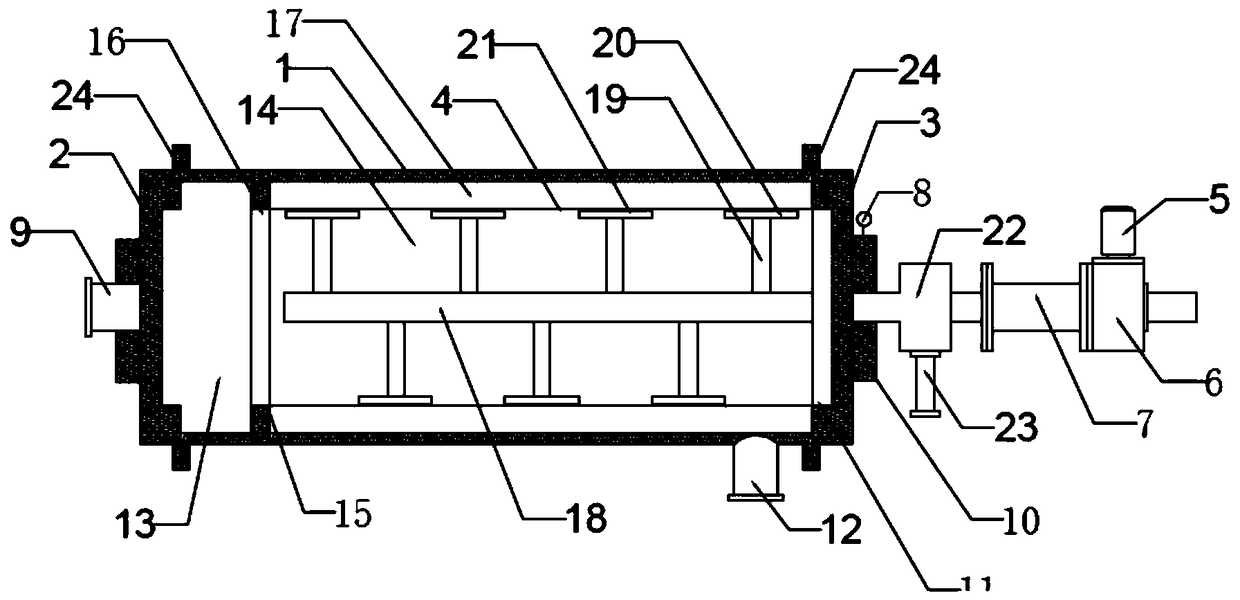

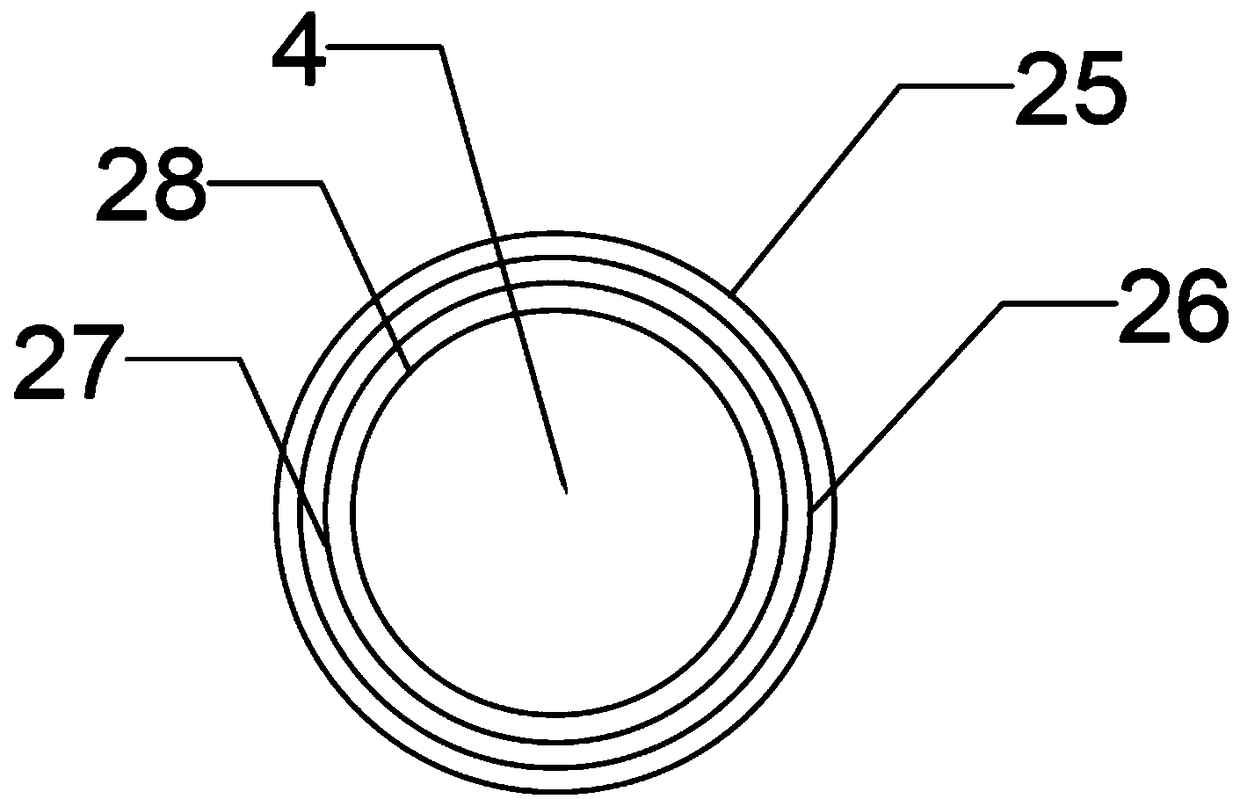

[0034] combine Figure 1-5, the present invention is a horizontal ship ballast water filter with a pleated filter net, comprising a horizontal cylindrical filter body 1, a circular front cover 2 and a rear cover at both ends of the shell of the body 1 Plate 3, filter element 4, backwashing system, driving motor 5, rotating mechanism 6, coupling 7, pressure sensor 8. The front cover 2 is provided with a water inlet 9, the outer side of the rear cover 3 is provided with a shaft installation port 10, and the inner side is provided with a filter bayonet 11, and the positions of the installation axes of the front cover 2 and the rear cover 3 coincide with the axis of the cylinder 1. Both the cover plate 2 and the rear cover 3 are fixedly connected with the cylinder body 1 by bolts 24 . A water outlet 12 is provided at the lower end of the casing of the cylinder body ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com