Multifunctional foam generation and foam performance testing device

A foam generation and testing device technology, applied to measuring devices, instruments, scientific instruments, etc., can solve the problems of uncontrollable foaming ratio, uncontrollable temperature conditions, uneven foam size, etc., to achieve high safety and avoid liquid backflow , the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

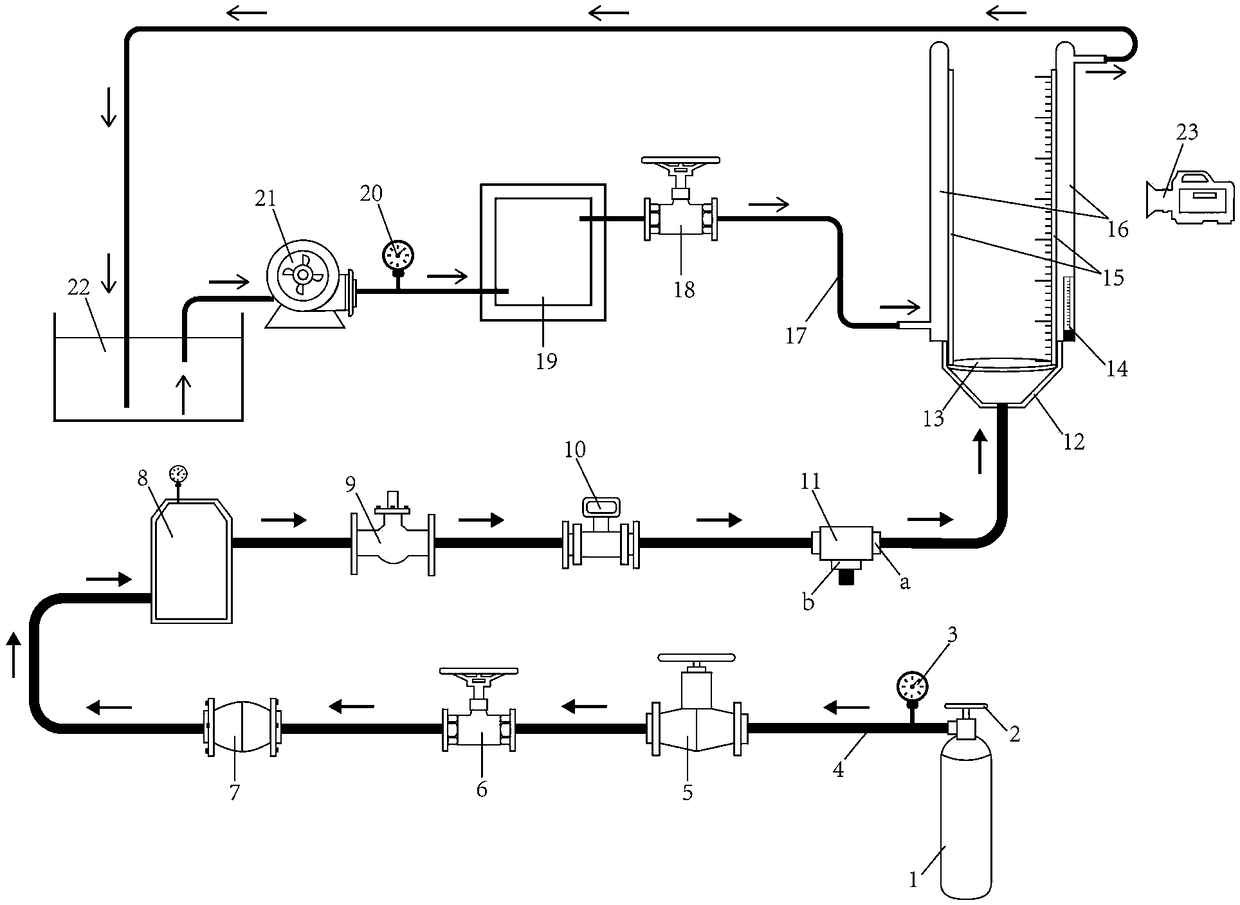

[0033] combine figure 1 , open the second gate valve 18, open the quantitative pump 21 and the water heating chamber 19, set the temperature to a fixed value, and after the temperature value in the water bath casing is stable, open the first gate valve 6, close the a port of the three-way valve 11, and open the three-way Open port b of valve 11, then open valve 2 of the high-pressure gas cylinder, set the pressure at 0.3-0.4MPa, the high-pressure gas passes through the gas pipeline 4, and passes through the pressure stabilizing valve 5, the first gate valve 6, and the one-way valve 7 successively , buffer tank 8, pressure relief valve 9, gas flow meter 10, port b of three-way valve 11, adjust the gas flow meter to 10L / h, after the flow is stable, close port b of three-way valve 11, and open the three-way valve Port a of 11, let the gas enter the glass funnel 12, pass through the porous glass disc 13 and mix with the 10mL foam liquid I pre-filled in the glass tube 15 to generat...

Embodiment 2

[0035] combine figure 1 , open the second gate valve 18, open the quantitative pump 21 and the water heating chamber 19, set the temperature to a fixed value, and after the temperature value in the water bath casing is stable, open the first gate valve 6, close the a port of the three-way valve 11, and open the three-way Open port b of valve 11, then open valve 2 of the high-pressure gas cylinder, set the pressure at 0.3-0.4MPa, the high-pressure gas passes through the gas pipeline 4, and passes through the pressure stabilizing valve 5, the first gate valve 6, and the one-way valve 7 successively , buffer tank 8, pressure relief valve 9, gas flow meter 10, port b of three-way valve 11, adjust the gas flow meter to 10L / h, after the flow is stable, close port b of three-way valve 11, and open the three-way valve Port a of 11, let the gas enter the glass funnel 12, pass through the porous glass disc 13 and mix with the 10mL foam solution I pre-filled in the glass tube 15, and sta...

Embodiment 3

[0037] combine figure 1 , open the second gate valve 18, open the quantitative pump 21 and the water heating chamber 19, set the temperature 1, after the temperature value in the water bath casing is stable, open the first gate valve 6, close the a port of the three-way valve 11, and open the three-way valve 11 b port, then open the high-pressure gas cylinder valve 2, set the pressure at 0.3-0.4MPa, the high-pressure gas passes through the gas pipeline 4, and successively passes through the pressure stabilizing valve 5, the first gate valve 6, the one-way valve 7, the buffer Tank 8, pressure relief valve 9, gas flow meter 10, port b of three-way valve 11, adjust the gas flow meter to 10L / h, after the flow is stable, close port b of three-way valve 11, open the port of three-way valve 11 port a, the gas enters the glass funnel 12, passes through the porous glass disc 13 and mixes with the 10mL foam solution I pre-filled in the glass tube 15, and starts to generate foam. After t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com