An experimental device for measuring the diffusion coefficient of natural gas

A diffusion coefficient and experimental device technology, applied in the direction of measuring device, diffusion analysis, measuring fluid pressure, etc., can solve the problems of no formation, lower internal pressure, crushed samples, etc., to ensure the safety of the experiment, the stability of the internal pressure, and the consistency sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with accompanying drawing:

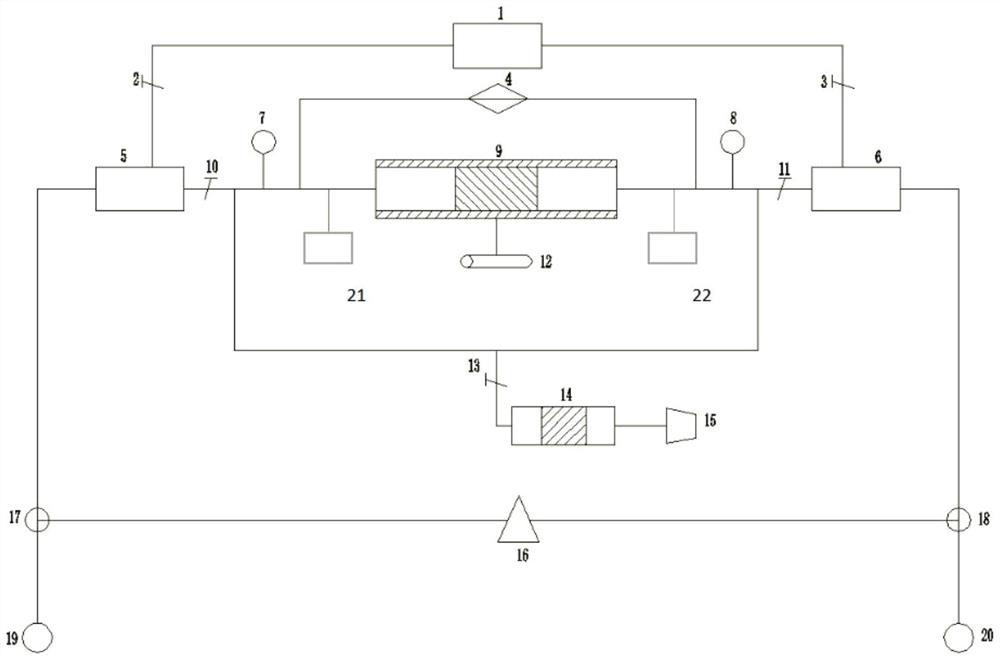

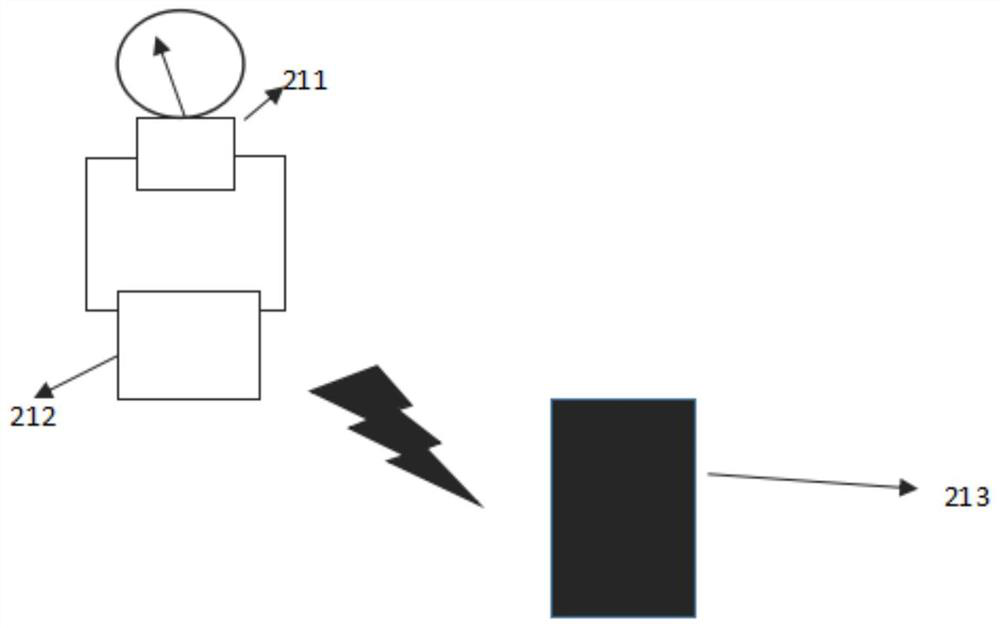

[0022] like figure 1 Shown: including gas chromatograph 1, first measuring valve 2, second measuring valve 3, differential pressure sensor 4, first sample chamber 5, second sample chamber 6, first pressure gauge 7, second pressure gauge 8 , core holder 9, first sampling valve 10, second sampling valve 11, confining pressure pump 12, valve 13, piston intermediate container 14, high precision constant speed and constant pressure pump 15, vacuum pump 16, first multi-way valve 17 , the second multi-way valve 18, the first gas source gas cylinder 19, the second gas source gas cylinder 20, the first pressure sensing alarm device 21 and the second pressure sensing alarm device 22, the gas chromatograph is respectively connected to the first measuring valve and a second measuring valve, the other ends of the first measuring valve and the second measuring valve are respectively co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com