Rapid gas chromatograph cooling device

A technology of gas chromatograph and cooling device, which is applied in the field of rapid cooling device of gas chromatograph, which can solve the problems of consuming analysis sample time, reducing work efficiency, prolonging cooling time, etc., and achieves faster wind speed, higher cooling efficiency, and faster air flow Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

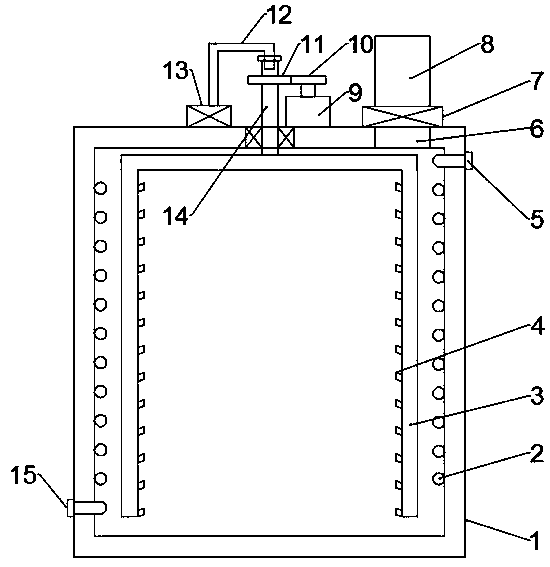

[0019] see figure 1 , in an embodiment of the present invention, a gas chromatograph rapid cooling device includes a column box 1, a motor 9, an exhaust fan 7 and a suction fan 13, the top side of the column box 1 is provided with an air outlet 6, and the air outlet 6 is installed with Exhaust fan 7, exhaust pipe 8 is installed on the exhaust fan 7 through screws, the inner wall of the column box 1 has a cooling water pipe 2 through a mounting ring and screws, the cooling water pipe 2 is spiral, and one end of the cooling water pipe 2 is provided with a cooling water inlet 15 The other end of the cooling water pipe 2 is provided with a cooling water outlet 5, and a hollow shaft 14 is pierced in the middle of the top of the column box 1. The hollow shaft 14 is rotatably connected with the top of the column box 1 through a bearing, and the bottom of the hollow shaft 14 is welded and fixed with an inverted U shape. Shaft 3, both sides of the inverted U-shaped shaft 3 are close to...

Embodiment 2

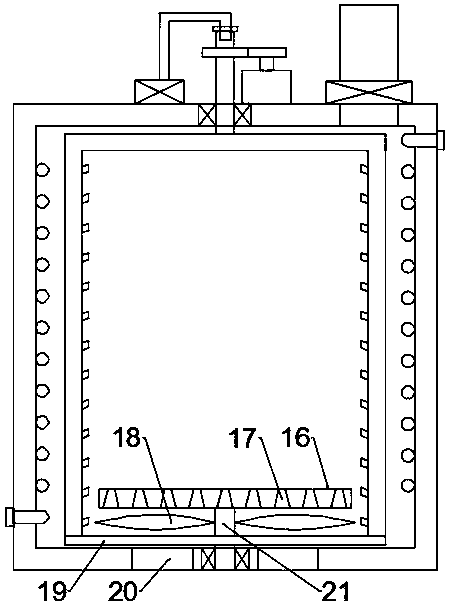

[0021] see figure 2 The difference between this embodiment and Embodiment 1 is that the bottom of the column box 1 is equipped with a rotating shaft 21 through bearings, and the bottom of the column box 1 is provided with air inlets 20 on both sides of the rotating shaft 21, and the air inlets 20 are installed with screws. Dust-proof net, the bottom end of the inverted U-shaped shaft 3 is welded and fixed with the rotating shaft 21 through the fixing rod 19, the top of the rotating shaft 21 is equipped with a disc 16, and a plurality of through holes 17 are evenly opened on the disc 16, and the through holes 17 have a small opening at the top The opening is large, and fan blades 18 are installed on the rotating shaft 21 below the disc 16. When the inverted U-shaped shaft 3 rotates, the fixed plate 19 drives the rotating shaft 21 to rotate, and the rotating shaft 21 drives the fan blades 18 and the disc 16 to rotate. The aperture of the hole 17 makes the wind speed of the fan ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com