Heat transfer coefficient test apparatus and heat transfer coefficient measuring method

A thermal conductivity and testing device technology, which is applied in the field of measurement, can solve the problems of high device complexity and difficulty in thermal conductivity, and achieve the effects of improving operability, accurately measuring heat transfer power, and avoiding errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

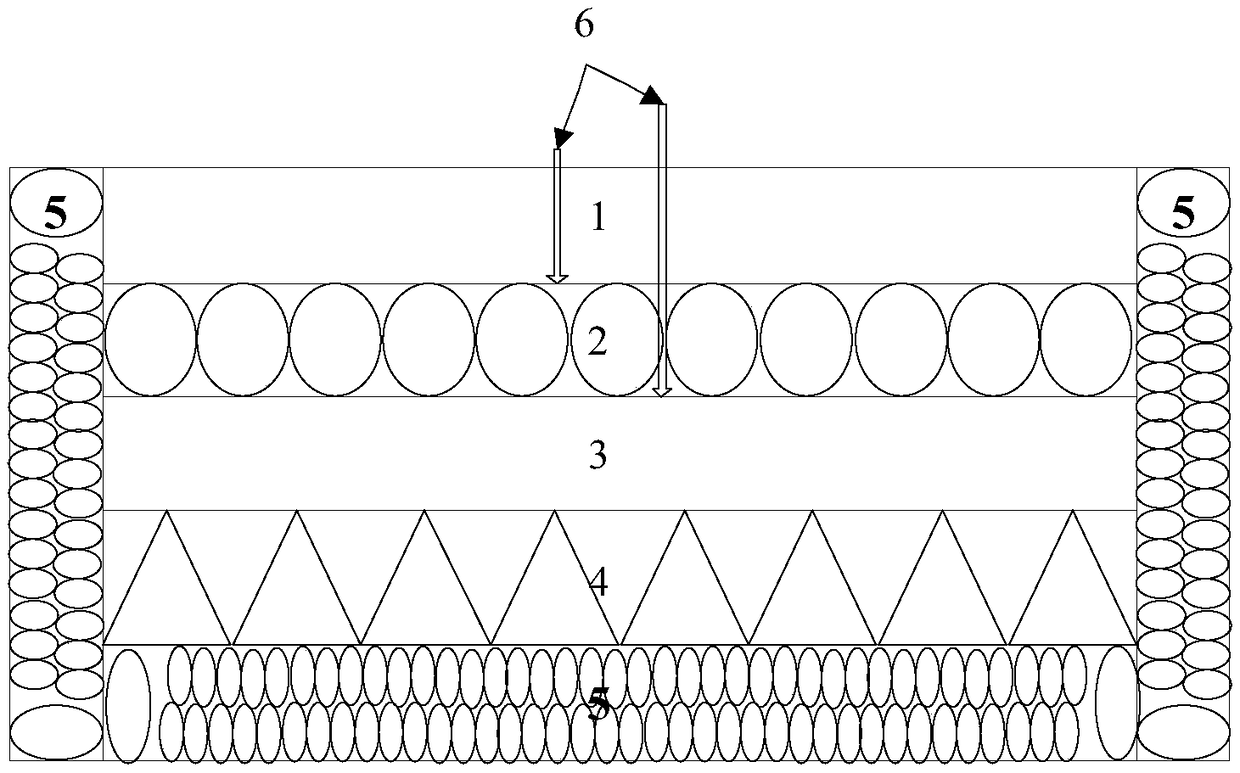

Image

Examples

Embodiment 2

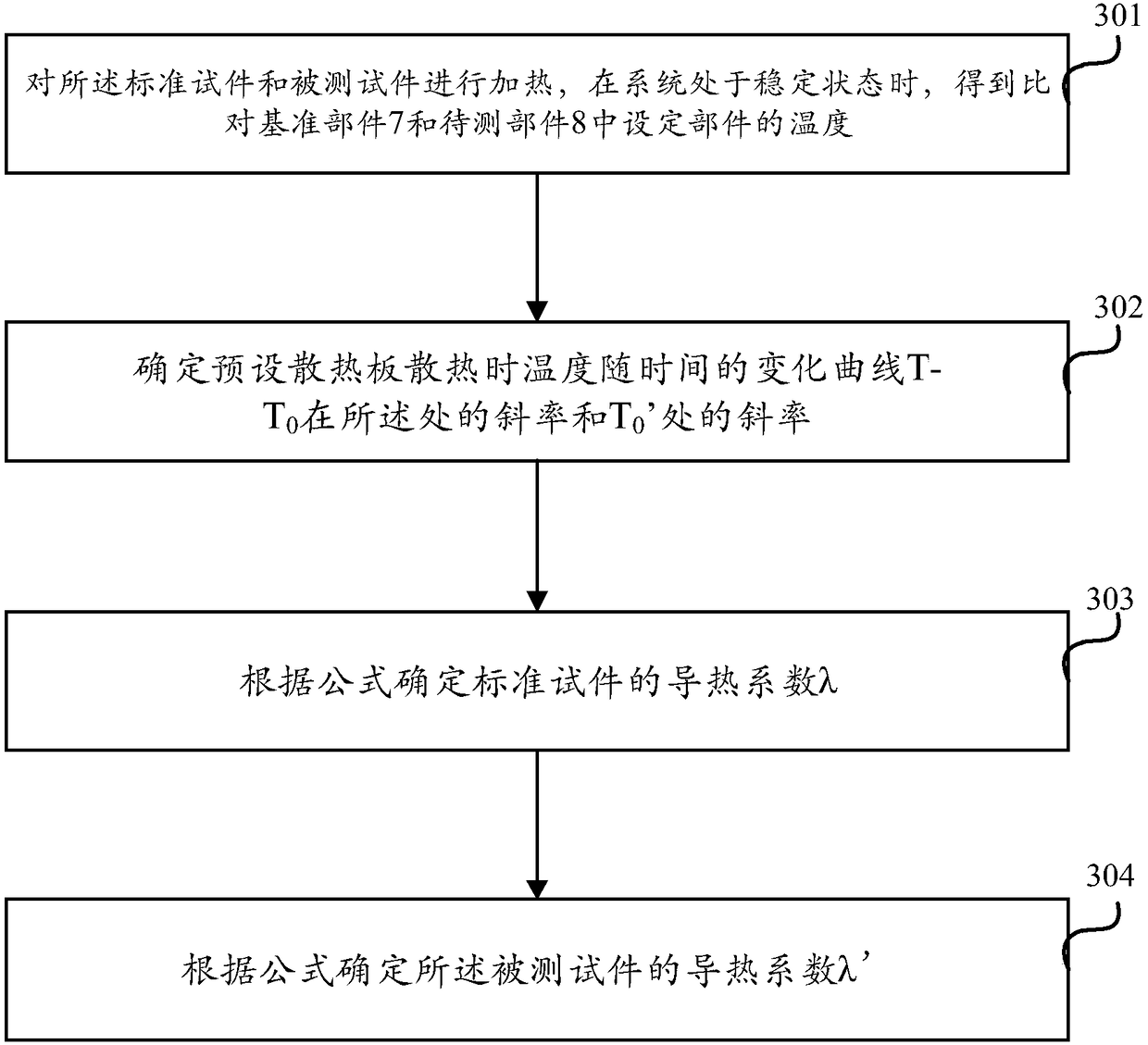

[0074] Such as image 3 As shown, in combination with the device provided in Embodiment 1, the embodiment of the present application also provides a method for measuring the thermal conductivity of a sample using the thermal conductivity testing device provided in Embodiment 1. The method includes steps:

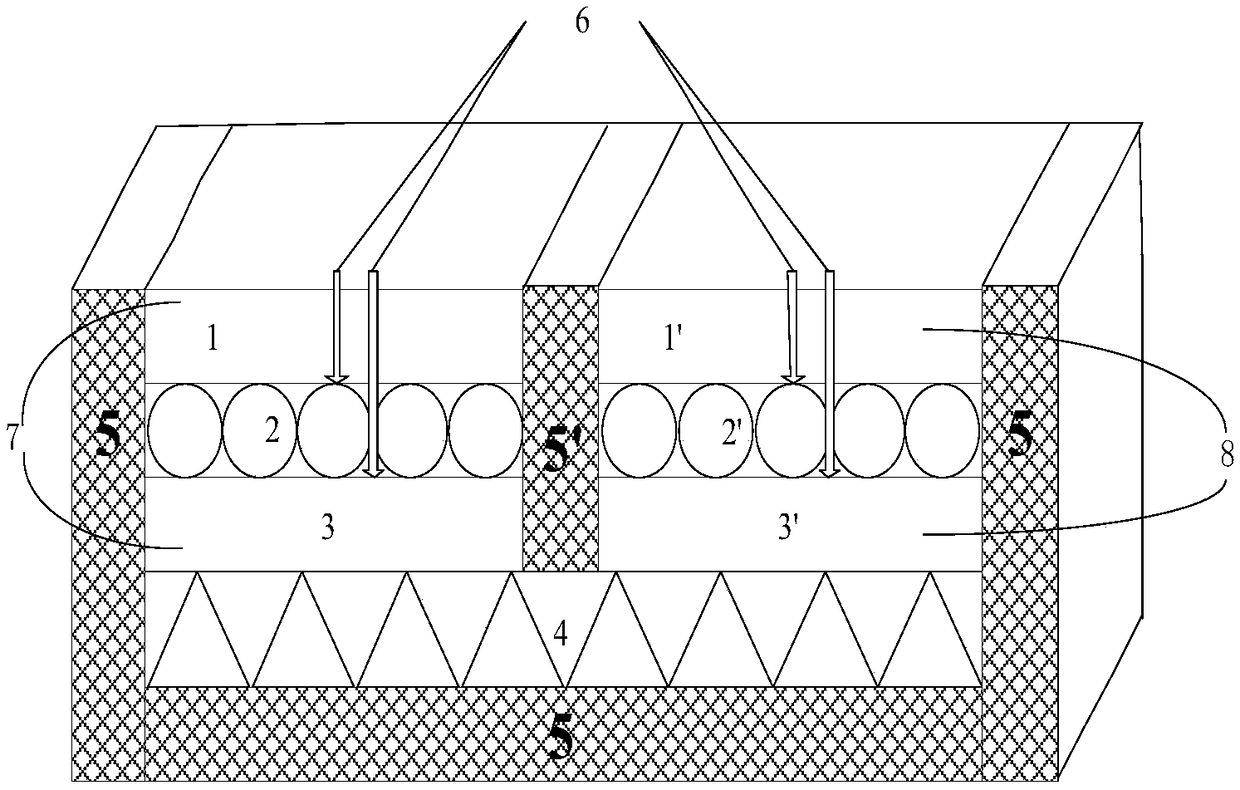

[0075] In step 301, the standard test piece and the tested piece are heated, and when the system is in a stable state, the temperatures of the set components in the comparison reference component 7 and the component to be tested 8 are obtained.

[0076] Wherein, comparing the temperature of the set components in the reference component 7 and the component to be tested 8 includes: the temperature T of the first heat dissipation plate 0 , the temperature T of the second cooling plate 0 ′, the upper surface temperature T of the standard test piece 1 , the temperature T of the lower surface 2 , the upper surface temperature T of the tested piece 1 ’ and the temperature T of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com