Device for measuring metal linear expansion coefficient based on pinhole imaging

A small hole imaging and metal wire technology, which is applied in the field of laser measurement, can solve the problems of complex optical path adjustment, low measurement accuracy, and low magnification, and achieve the effects of low optical path adjustment requirements, accurate measurement results, and safe and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

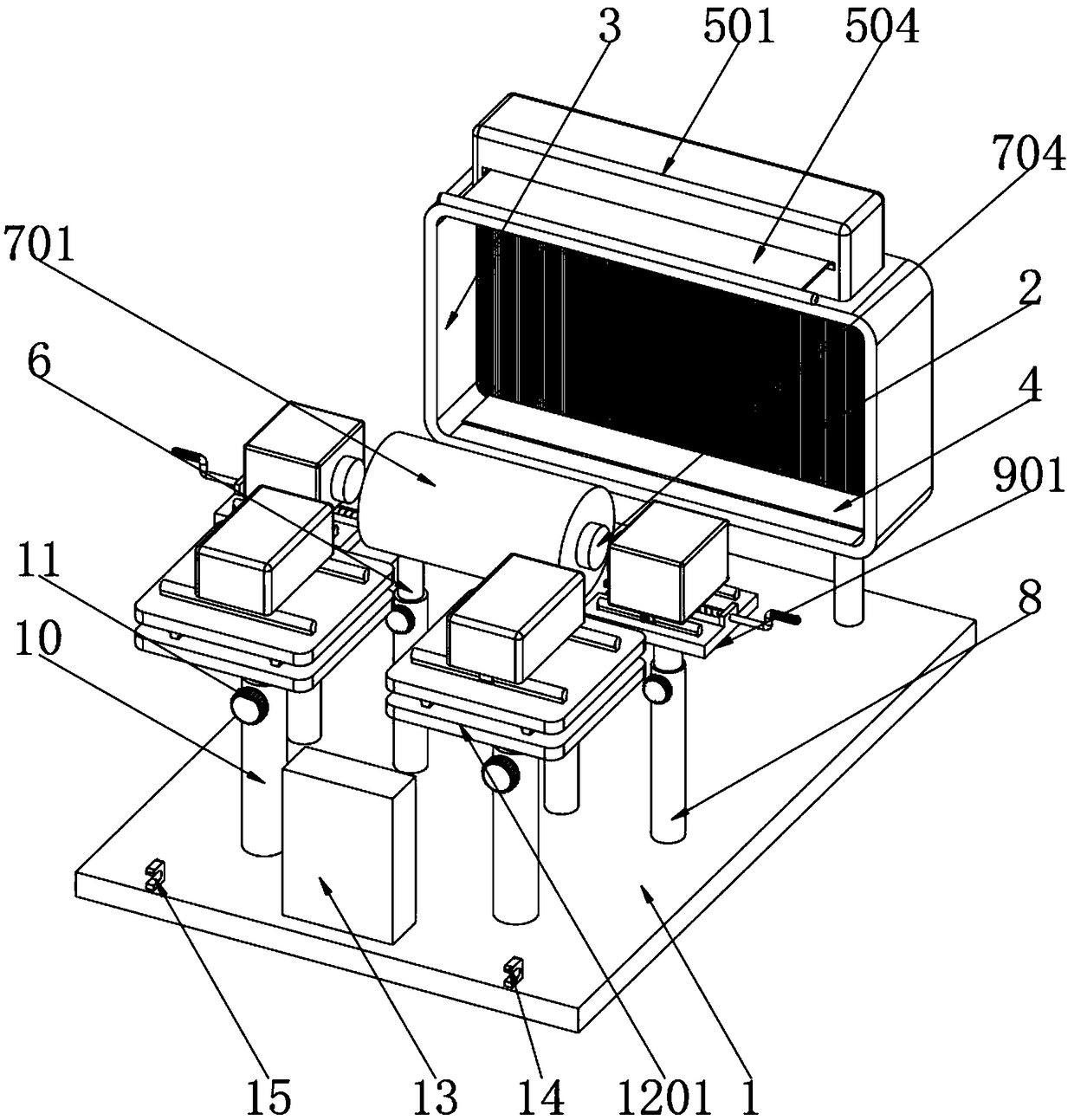

[0043] Example: such as Figure 1-7 As shown, the present invention provides a technical solution, a device for measuring the linear expansion coefficient of metal based on small hole imaging, including a base plate 1, one end of the base plate 1 is welded with a light screen 2 through a support rod, and one side of the light screen 2 is installed by welding There is a cover 3. In order to facilitate direct reading of data, one side of the light screen 2 is pasted with alternate light and dark stripes, and the distance between the stripes is 0.1 mm. In order to absorb the external light, the light on the surface of the light screen 2 More clearly, the inner wall of the shielding cover 3 is coated with black paint, and the inner bottom of the shielding cover 3 is pasted with a black recording board 4;

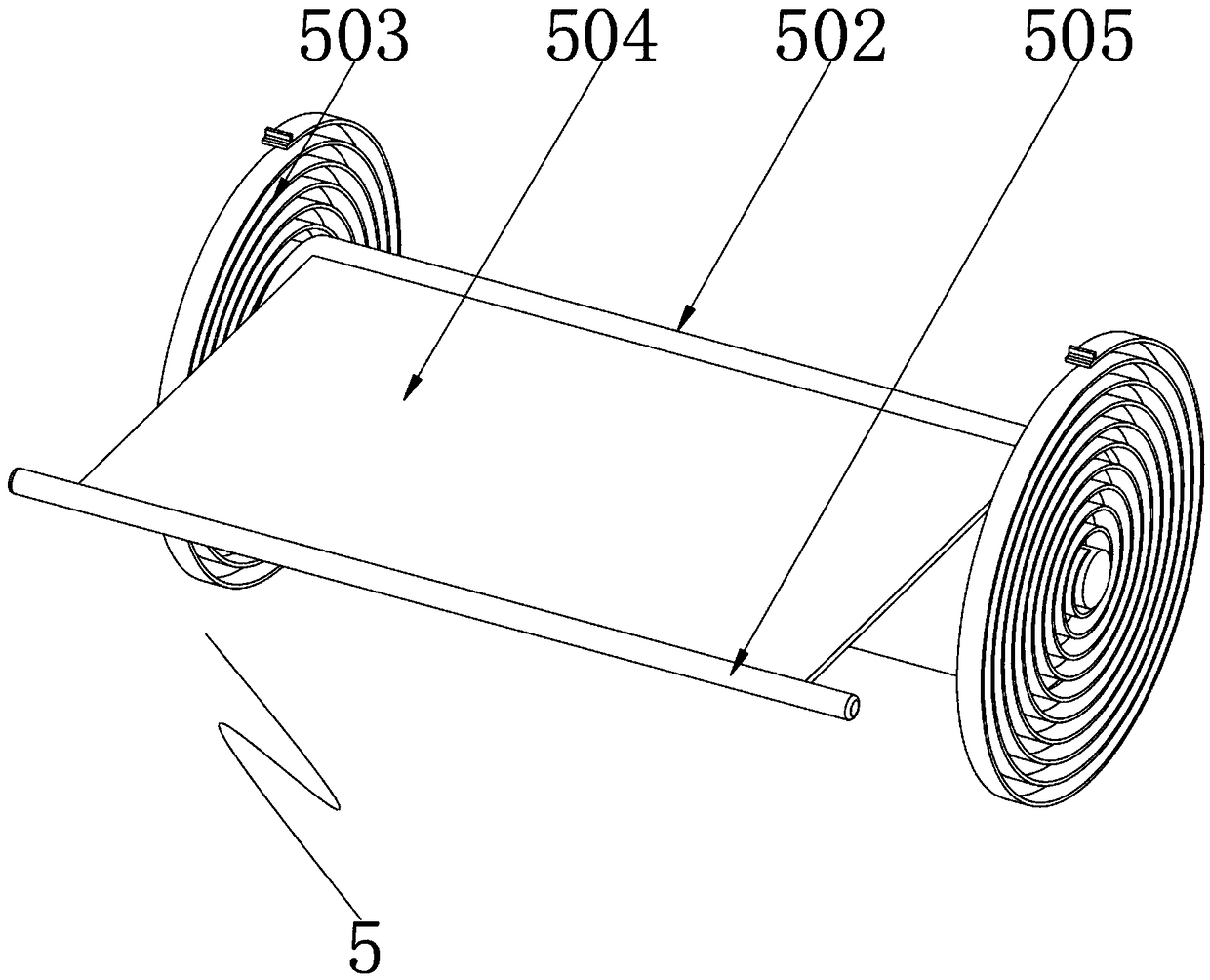

[0044] A dust-proof assembly 5 is installed on the top of the light screen 2, and the dust-proof assembly 5 includes a storage box 501, a take-up roller 502, a plane scroll spri...

Embodiment 2

[0053] Embodiment 2: The measurement method of the device for measuring the linear expansion coefficient of metal based on pinhole imaging, comprising the following steps:

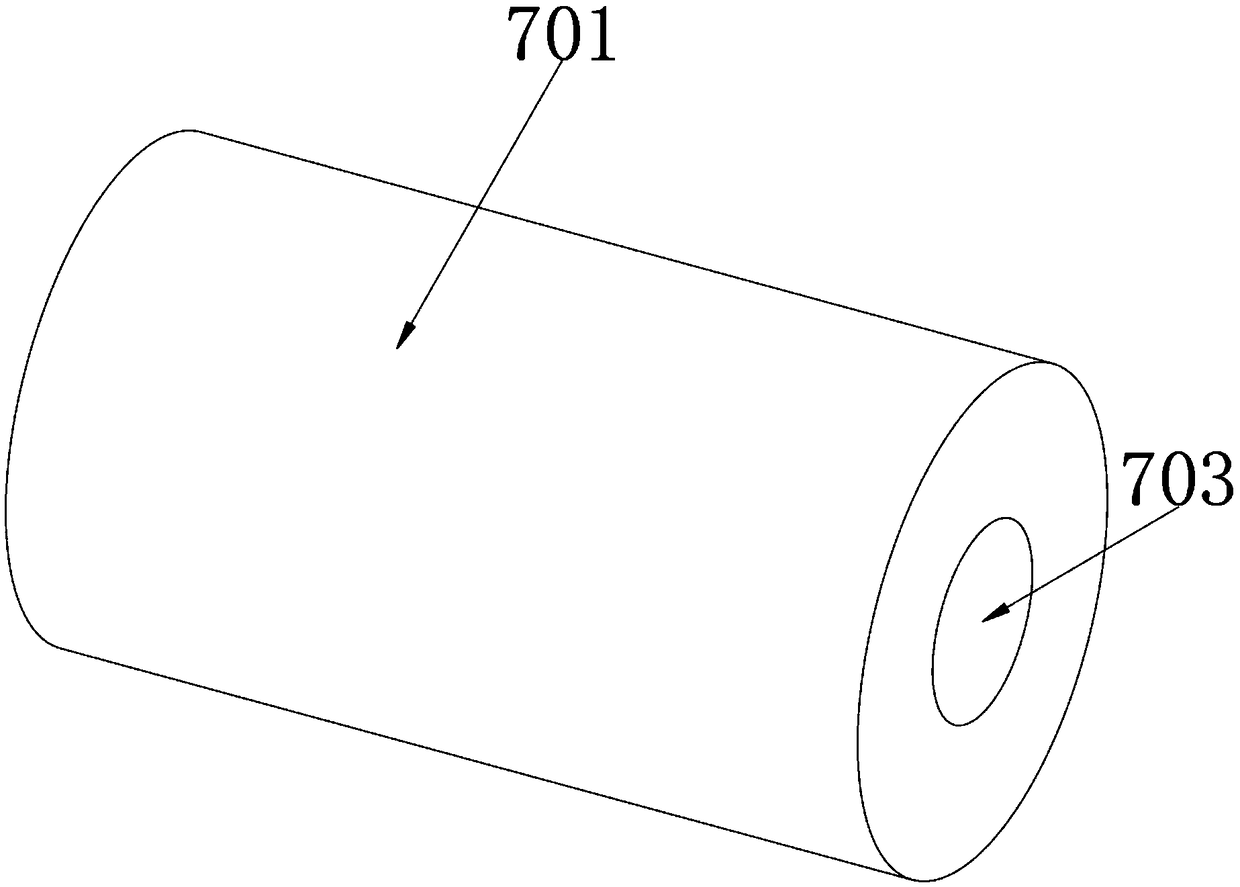

[0054] (1) Measure the original length L of the metal rod 704 0 Finally, the metal rod 704 is inserted into the slot 703, and the positions and heights of the x-axis displacement block 905 and the laser emitter 1208 at both ends of the metal rod 704 are adjusted so that the light energy of the laser emitter 1208 passes through the x-axis displacement block 905 and the laser emitter 1208. The gap formed by one end of the metal rod 704 hits the light screen 2 to form a beam of light;

[0055] (2) Move the x-axis displacement block 905 of the miniature x-axis displacement assembly 9, and record the moving length ΔL, record the light column length variation ΔS on the black recording board 4 below the light screen 2 and record the data, repeat the operation several times and Record multiple sets of data;

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| distance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com