Hydraulic cylinder detection device

A detection device and hydraulic cylinder technology, which can solve the problem of inaccurate air tightness detection of hydraulic cylinders by detecting the appearance of fluid at the leakage point and measuring the liquid tightness by using liquid/vacuum degree, so as to ensure the air tightness Density, resource saving, and good coordination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The following is further described in detail through specific implementation methods:

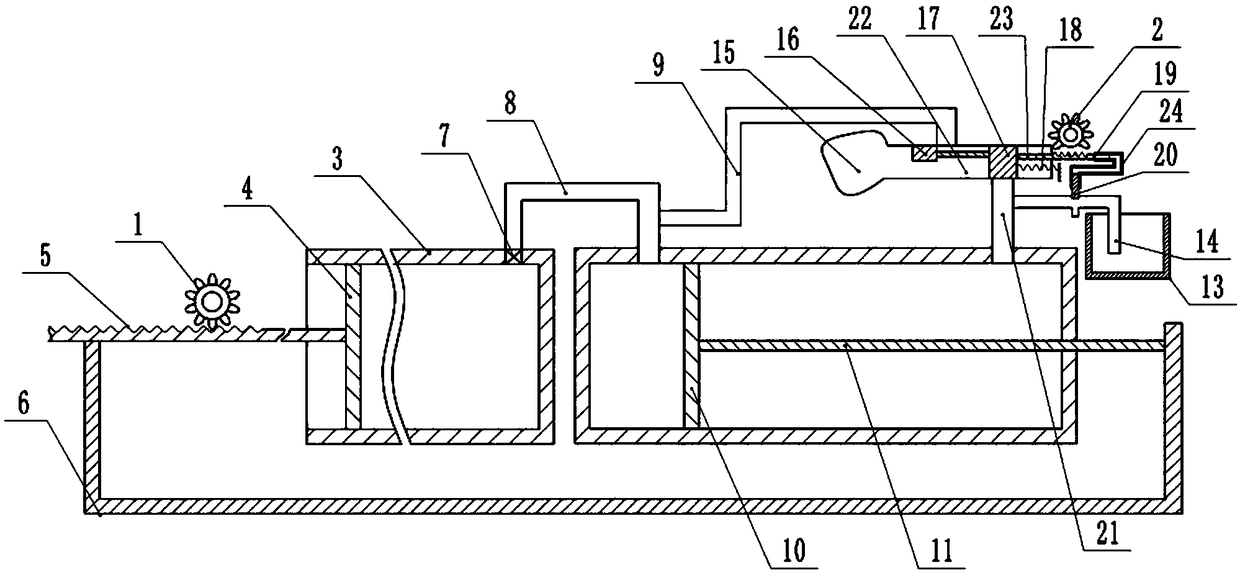

[0017] The reference signs in the drawings of the description include: gear 1, incomplete gear 2, piston barrel 3, slide plate 4, first rack 5, U-shaped connecting rod 6, air outlet valve 7, first pipeline 8, second pipeline 9 , piston 10, piston rod 11, detection groove 13, detection tube 14, elastic air bag 15, second stopper 16, first stopper 17, return spring 18, push rod 19, third stopper 20, vertical tube 21 , the horizontal pipe 22, the second rack 23.

[0018] The embodiment is basically as attached figure 1 Shown: hydraulic cylinder detection device, including frame, air intake unit, detection unit and limit parts, air intake unit includes first drive part and piston barrel 3, slide plate 4 is sealed and slidably connected inside piston barrel 3, piston barrel 3 There is an air outlet on the upper, and the first pipeline 8 is connected to the air outlet, and an air outlet ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com