System and method for detecting air leakage on combination surface of engine case

An engine casing and detection method technology, applied in the testing of machine/structural components, testing of fluid tightness, measuring devices, etc., can solve problems such as damage, high noise, and affecting engine efficiency, so as to improve the reliability of use, Avoid detecting missed effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

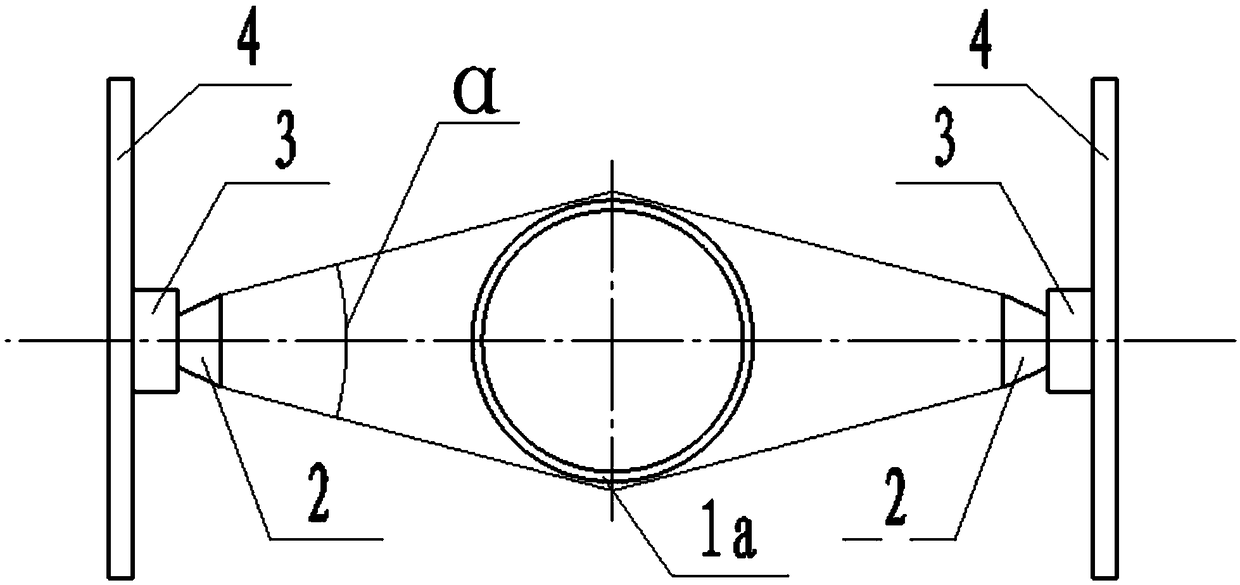

[0043] Such as Figure 4 As shown, the non-hand-held infrared thermometer is used to test the sealing of the joint surface of the circumferential installation edge of the casing.

[0044] 1) Non-handheld infrared thermometer model: FLUKE TIX580

[0045] (1) Temperature measurement range: -20~800℃.

[0046] (2) Thermal sensitivity: ≤0.05℃

[0047] (3) Temperature measurement accuracy: ±2°C

[0048] (4) Focusing system: Three focusing methods (multi-point autofocus, laser ranging autofocus, manual focus).

[0049] (5) Field of view: 32°C X 20°C

[0050] (6) Number of thermometers used: 4.

[0051] 2) Measurement data of the joint surface of the circumferential installation edge of the high-pressure compressor casing

[0052] The engine test speed is 96.58% N H , measure the temperature at the joint surface of the rear mounting edge of the high-pressure compressor casing, take an average of 120 test points along the circumferential direction, and record the temperature val...

Embodiment 2

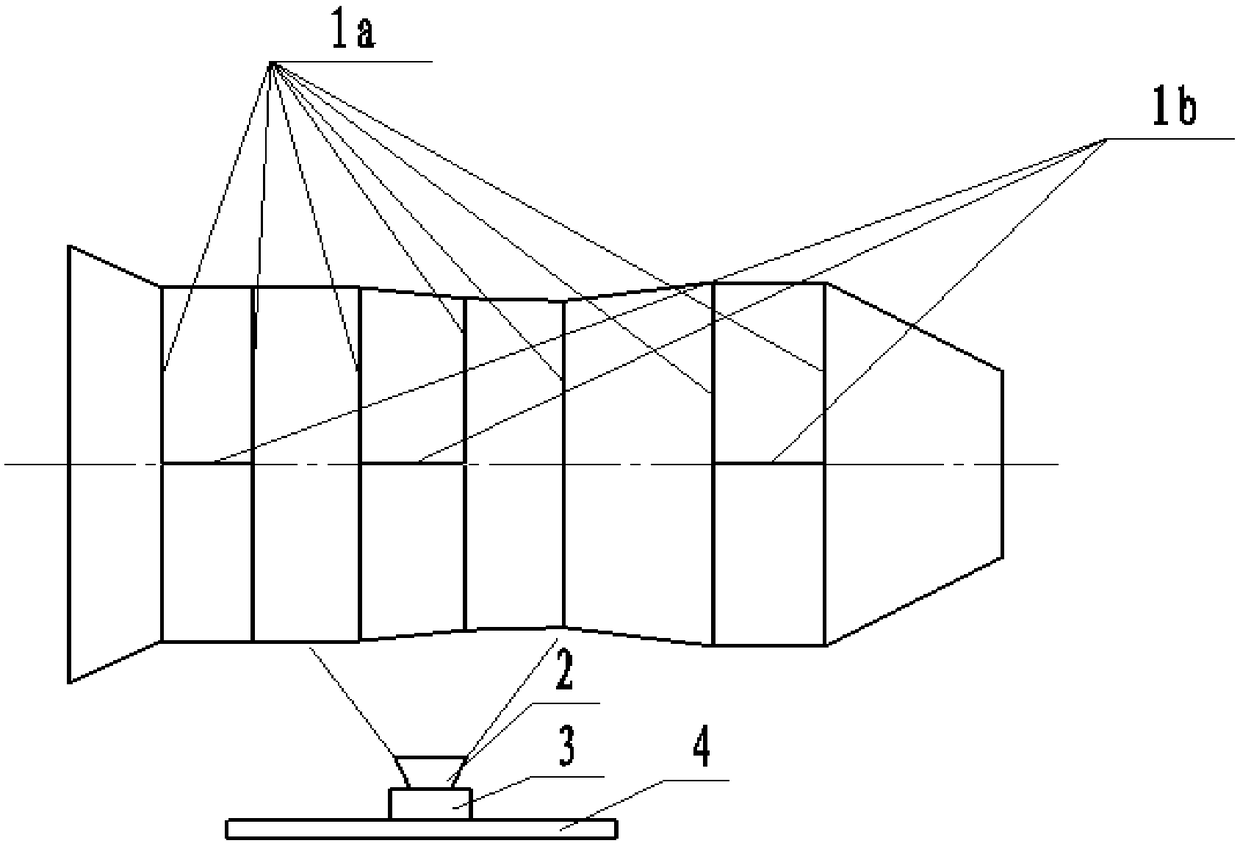

[0060] Such as Figure 5 As shown in , a non-hand-held infrared thermometer was used to test the sealing of the joint surface of the axial mounting edge of the casing.

[0061] 1) The model and parameters of the non-handheld infrared thermometer are the same as those in Embodiment 1.

[0062] 2) Measurement data of the joint surface of the axial mounting edge of the high-pressure compressor casing

[0063] The engine test speed is 95.38% N H , measure the temperature at the joint surface of the axial mounting edge of the high-pressure compressor casing, take an average of 60 test points along the axial direction, and record the temperature value of each test point in the following table:

[0064] The measured value of the temperature at the joint surface of the axial mounting edge of the high-pressure compressor casing (°C)

[0065] serial number

temperature

serial number

temperature

serial number

temperature

serial number

temperature

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com