Oil-saving and emission-reducing system of engine

A technology for engines and exhaust valves, applied in engine components, engine control, machines/engines, etc., can solve the problems of large starting work, effort, starter and battery damage, etc., and achieve the effect of reducing fuel consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

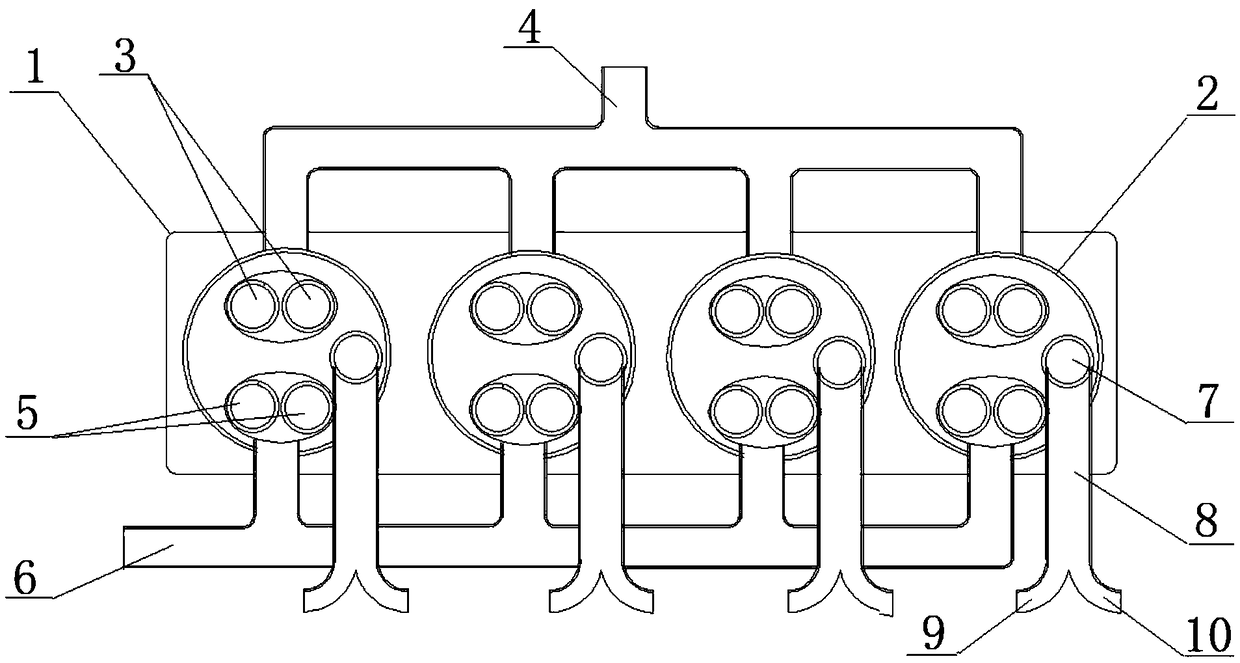

[0017] Such as figure 1 As shown, the present invention includes an engine 1, and several combustion chambers 2 located on the engine 1, each combustion chamber 2 includes two intake valves 3 and two exhaust valves 5, and also includes a decompression mechanism. The decompression mechanism includes a decompression valve 7, a decompression camshaft 16, a decompression runner 17 and a servo motor 20. The decompression valve 7 is arranged on each combustion chamber 2, and a decompression camshaft is arranged directly above the decompression door 7. 16. The decompression runner 17 at the end of the decompression camshaft 16 is connected to the servo motor 20; the decompression valve 7 is connected to the decompression pipe 8, and the end of the decompression pipe 8 is divided into two, which are divided into the intake branch pipe 9 and the exhaust pipe. Air branch pipe 10, wherein the intake branch pipe 9 is connected with the intake pipe 4 of the intake valve 3, and the exhaust ...

Embodiment 2

[0030] Such as figure 1 and figure 2 In the embodiment of the present invention given, the decompression pipe 8 is connected with the intake pipe 4 and the exhaust pipe 6 respectively, and the layout of the intake pipe 4 and the exhaust pipe 6 is selected according to actual needs, and is not limited to the main pipe of the intake pipe 4. The merging position of the exhaust pipe 6 is arranged in the middle of all the intake pipes 4, and the merging position of the main pipe of the exhaust pipe 6 is not limited to being arranged on the left side of all the exhaust pipes 6.

[0031] Similarly, the intake runner 15 at the end of the intake camshaft 14, the exhaust runner 19 at the end of the exhaust camshaft 18, the decompression runner 17 at the end of the decompression camshaft 16, and the decompression runner 17 at the end of the crank wheel The crank wheel 13 is not limited to being arranged on the right side of the combustion chamber 2, and can also be selected on the left...

Embodiment 3

[0035] The present invention can cooperate with the sensor to constitute the control system for fuel saving and emission reduction of the engine 1 .

[0036] When the cylinder deactivation system is working, the cylinder pressure information in the combustion chamber 2 of the engine 1 is collected through the mass-produced piezoresistive cylinder pressure sensor arranged in the cylinder, and the crankshaft 12 of the engine 1 is determined according to the cylinder pressure information in the combustion chamber 2 of the engine 1 phase information, and then determine the speed information of the engine 1 according to the phase information of the crankshaft 12 of the engine 1; finally, the controller of the engine 1 judges and drives the injector according to the phase information and speed information of the engine 1. When it is detected that the rotational speed information of the transmitter exceeds 800r / min, the crankshaft motor 11 driving the crankshaft 12 does not intervene ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com