Underwater drilling tool attitude detection system

A technology of caisson and cutting edge, applied in drilling tools, automatic control system of drilling, measurement, etc., can solve the problems of excavation trajectory deviation, unsatisfactory final effect, heavy weight, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The technical solution of the present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

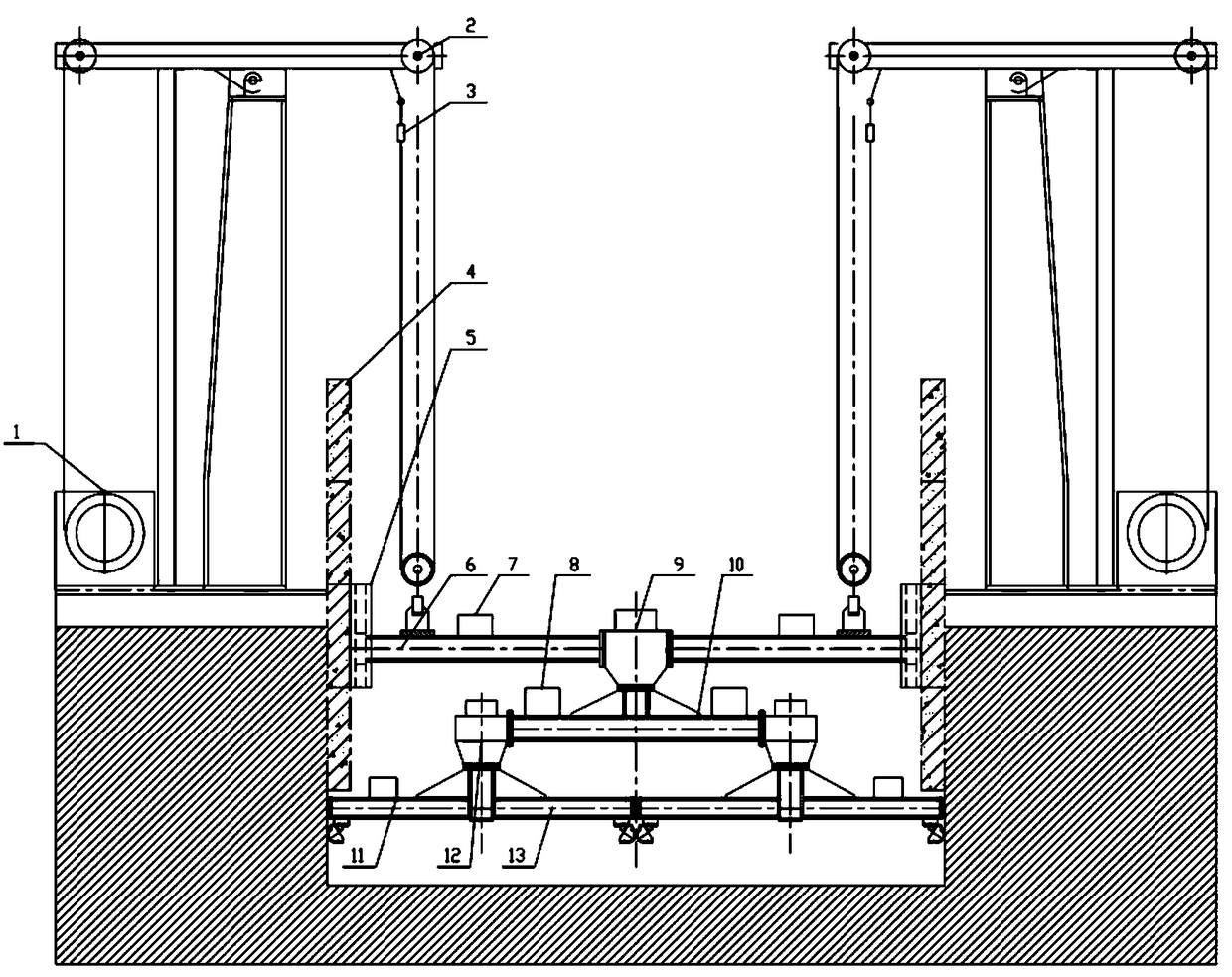

[0016] like figure 1 As shown, the underwater drilling tool posture detection system includes a driving mechanism, a power lifting mechanism arranged on the ground for lifting and releasing the driving mechanism, and an operation control system for controlling the operation of the above-mentioned mechanisms; the driving mechanism It includes a tunneling frame 6, a drill boom 10, a main drive device 9 for driving the drill boom to rotate, a drilling tool 13, an auxiliary drive device 12 for driving the drill tool to rotate, and the outer end of the tunneling frame is fixedly installed on The chute-type anti-torque device 5 on the shaft wall 4 slides and guides, and the pre-embedded steel plate on the shaft wall serves as the basis for welding the anti-torque chute. The main drive device 9 is installed on the tunneling ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com