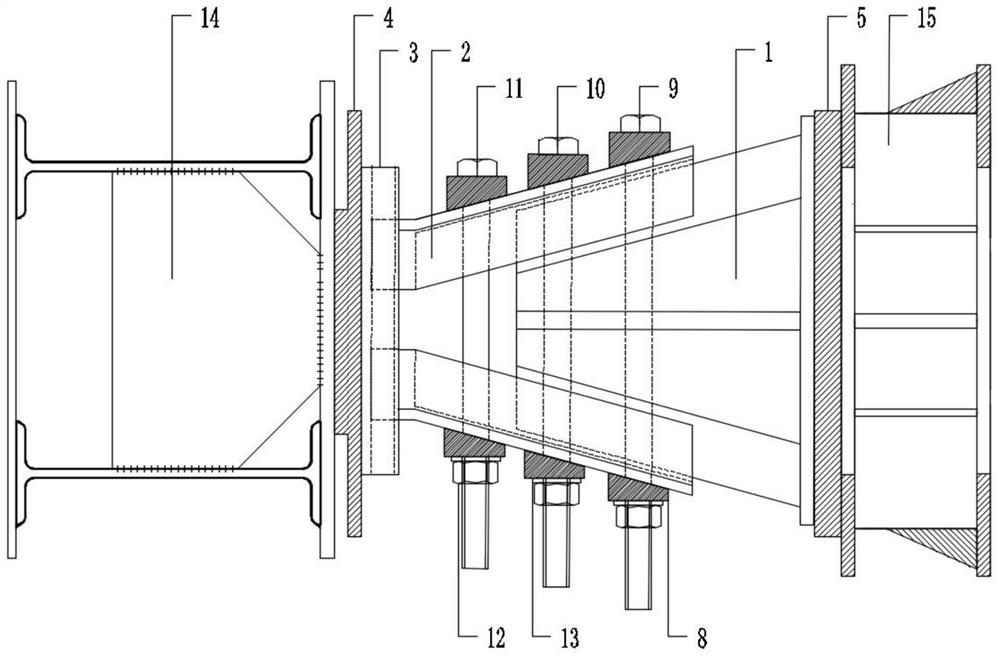

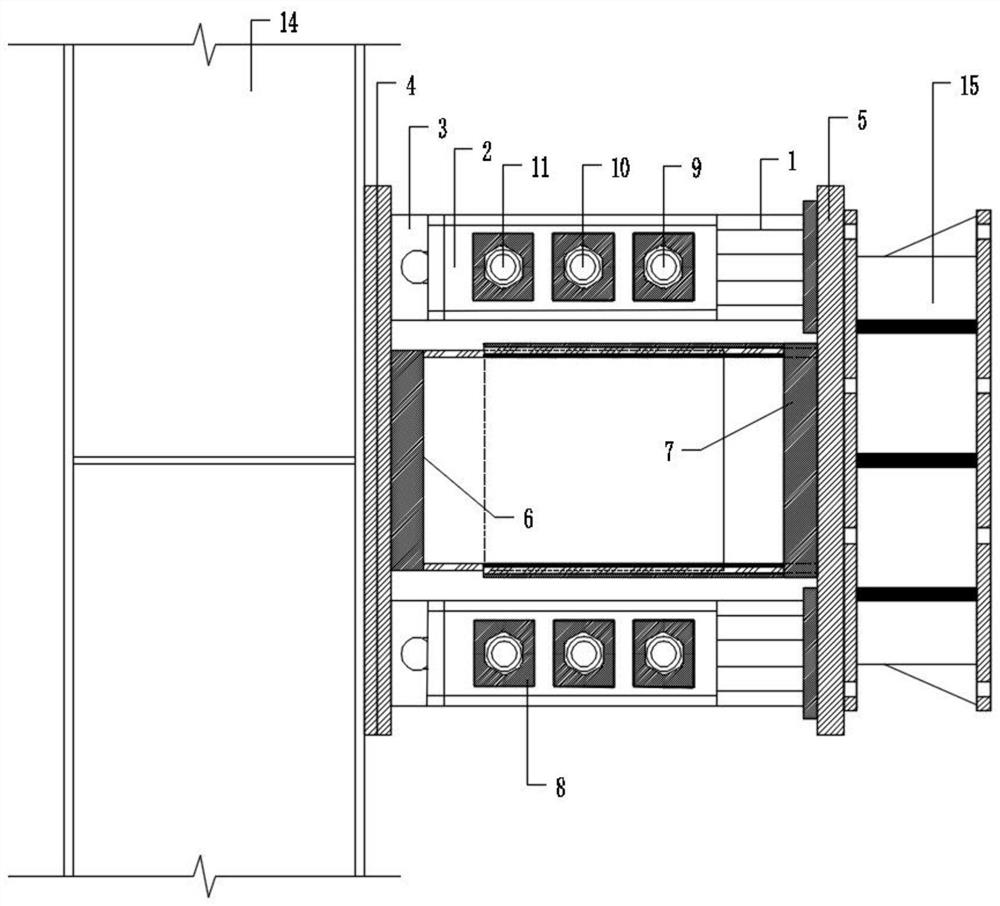

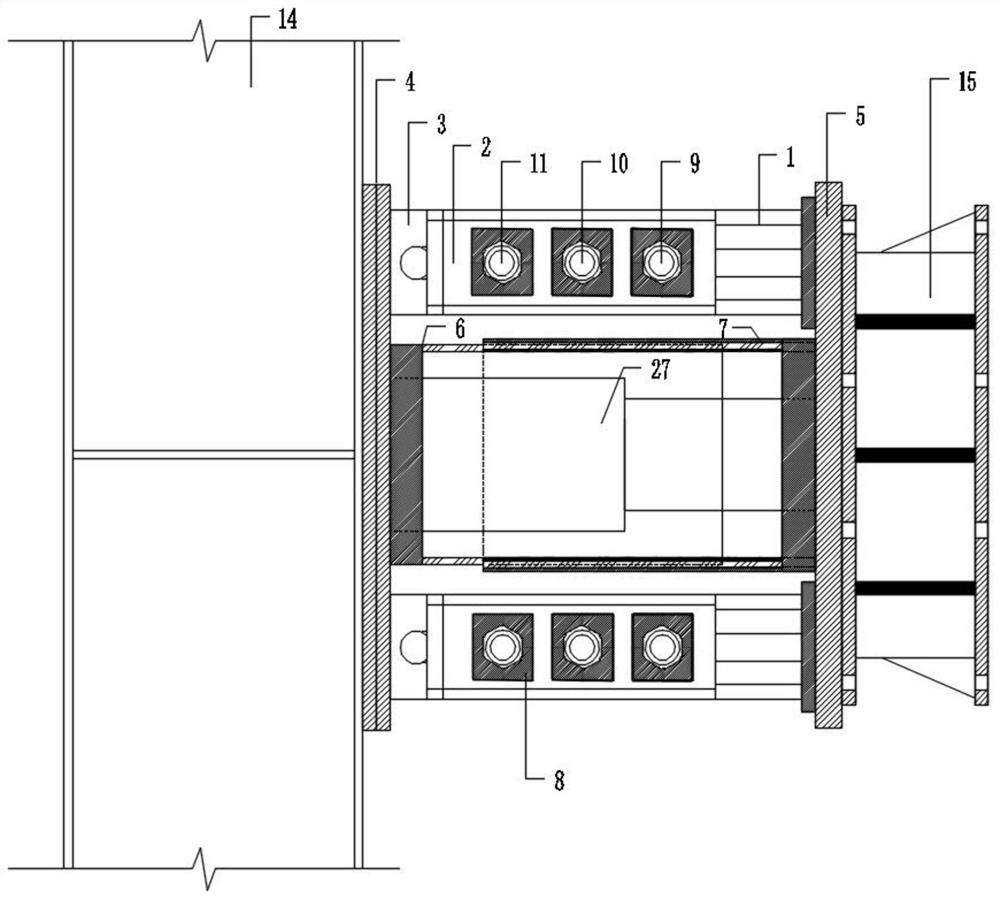

A nested detachable node with double outriggers for prefabricated support and its construction method

A nested, double outrigger technology, applied in excavation, pillars, infrastructure engineering, etc., can solve problems such as difficult quality control, insufficient rigidity and stability, and a large number of spare parts, achieving important engineering application value and development Foreground, on-site use is simple and fast, and the effect of a small number of components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0063] Example background:

[0064] The foundation pit of an open cut subway station has a total length of 598.5m, which is divided into three parts: the shield tunnel at the west end, the standard section and the shield tunnel at the east end. Among them, the standard section is 564.45m long, 20.2m wide, and 18.0m deep. gravel soil. The groundwater depth of the standard section of the station is 12m. A total of three Φ609 steel supports with a wall thickness of 16mm were erected, the spacing between the first support was 5.25m, and the spacing between the second and third supports was 5m. Using the double-leg nested detachable node for assembly support proposed by the present invention to carry out the scheme design of the detachable adjustment node of the first and third steel supports in the standard section of the foundation pit, the following application examples are proposed.

[0065] The specific processing and installation process is as follows:

[0066] All wedge-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com