Long-acting heavy anti-corrosion coating containing graphene-zinc powder and preparation method thereof

A graphene and heavy-duty anti-corrosion technology, applied in the direction of anti-corrosion coatings, polyamide coatings, epoxy resin coatings, etc., can solve the problems of reduced anti-corrosion efficiency, health hazards of workshop personnel, and increased weight, so as to reduce the content of zinc powder, Excellent anti-corrosion performance, the effect of large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

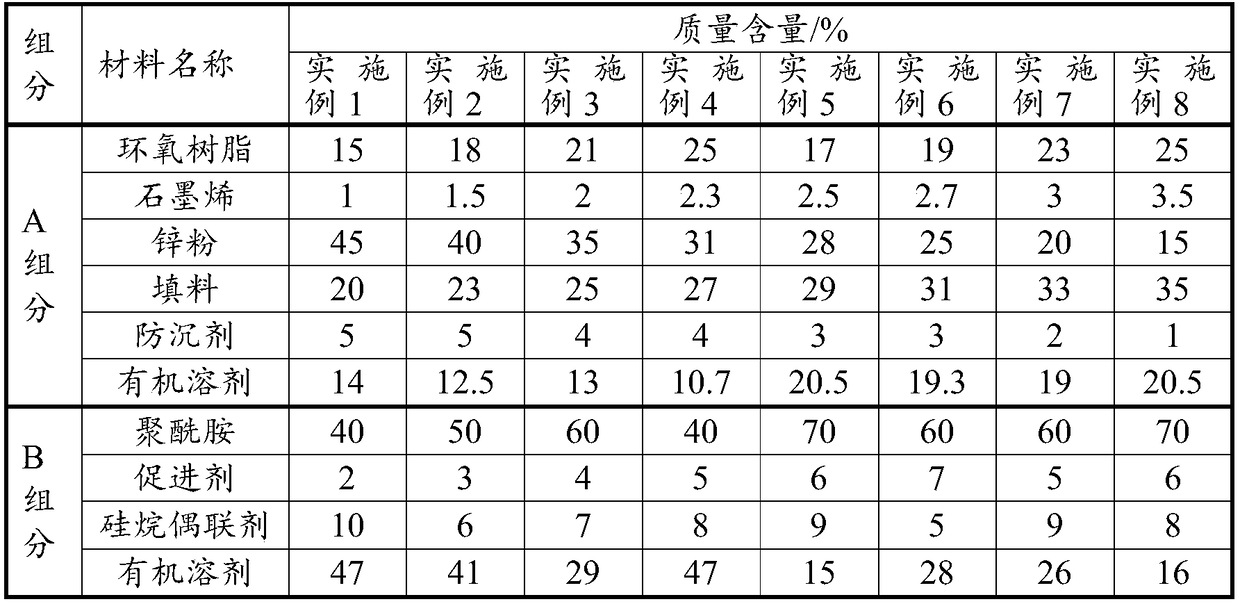

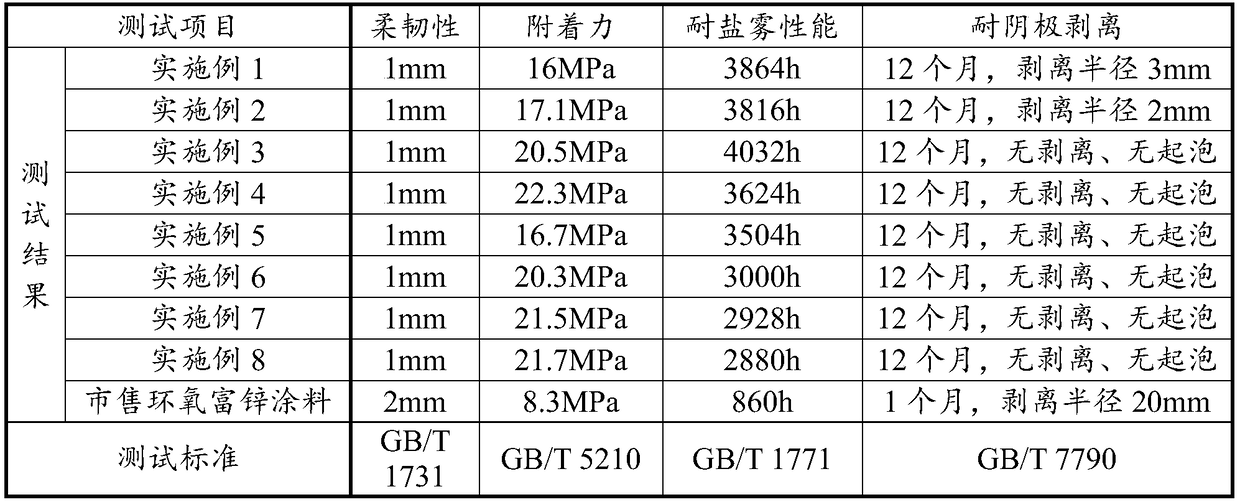

Examples

Embodiment 1

[0050] A kind of preparation method of graphene-zinc powder long-acting anticorrosion coating, concrete steps are as follows:

[0051] Ⅰ. Preparation method of component A of heavy-duty anti-corrosion coating:

[0052] (1) Add the epoxy resin, graphene, filler, and solvent in the formula of A component into the stirring container, and stir at 1200r / min until the dispersion is uniform;

[0053] (2) The mixture obtained in step (1) is added to a conical grinder for grinding, and the particle size of the slurry after grinding is 25 μm;

[0054] (3) Add the zinc powder and anti-sedimentation agent in the formula amount of component A to the mixture obtained in step (2), and stir at 2000r / min until uniformly dispersed;

[0055] (4) Add the mixture obtained in step (3) to a conical grinder for grinding, and the particle size of the slurry after grinding is 30 μm to obtain component A;

[0056] Ⅱ. Preparation method of component B of heavy-duty anti-corrosion coating:

[0057] (5)...

Embodiment 2

[0060] A kind of preparation method of graphene-zinc powder long-acting anticorrosion coating, concrete steps are as follows:

[0061] Ⅰ. Preparation method of component A of heavy-duty anti-corrosion coating:

[0062] (1) Add the epoxy resin, graphene, filler, and solvent in the formula of A component into the stirring container, and stir at 1000r / min until the dispersion is uniform;

[0063] (2) The mixture obtained in step (1) is added to a conical grinder for grinding, and the particle size of the slurry after grinding is 15 μm;

[0064] (3) Add the zinc powder and anti-sedimentation agent in the formula amount of component A to the mixture obtained in step (2), and stir at 1200r / min until uniformly dispersed;

[0065] (4) Add the mixture obtained in step (3) to a conical grinder for grinding, and the particle size of the slurry after grinding is 45 μm to obtain component A;

[0066] Ⅱ. Preparation method of component B of heavy-duty anti-corrosion coating:

[0067] (5)...

Embodiment 3

[0070] A kind of preparation method of graphene-zinc powder long-acting anticorrosion coating, concrete steps are as follows:

[0071] Ⅰ. Preparation method of component A of heavy-duty anti-corrosion coating:

[0072] (1) Add the epoxy resin, graphene, filler, and solvent in the formula of A component into the stirring container, and stir at 1500r / min until the dispersion is uniform;

[0073] (2) The mixture obtained in step (1) is added to a conical grinder for grinding, and the particle size of the slurry after grinding is 20 μm;

[0074] (3) Add the zinc powder and anti-sedimentation agent in the formula amount of component A to the mixture obtained in step (2), and stir at 2000r / min until uniformly dispersed;

[0075] (4) Add the mixture obtained in step (3) to a conical grinder for grinding, and the particle size of the slurry after grinding is 25 μm to obtain component A;

[0076] Ⅱ. Preparation method of component B of heavy-duty anti-corrosion coating:

[0077] (5)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| adhesivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com