Marble back coating glue based on stone waste slurry material and preparation method of glue

A waste slurry and back-coating technology, which is applied in the field of marble back-coating and its preparation, achieves good application prospects, improves sticking strength, and efficiently utilizes resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

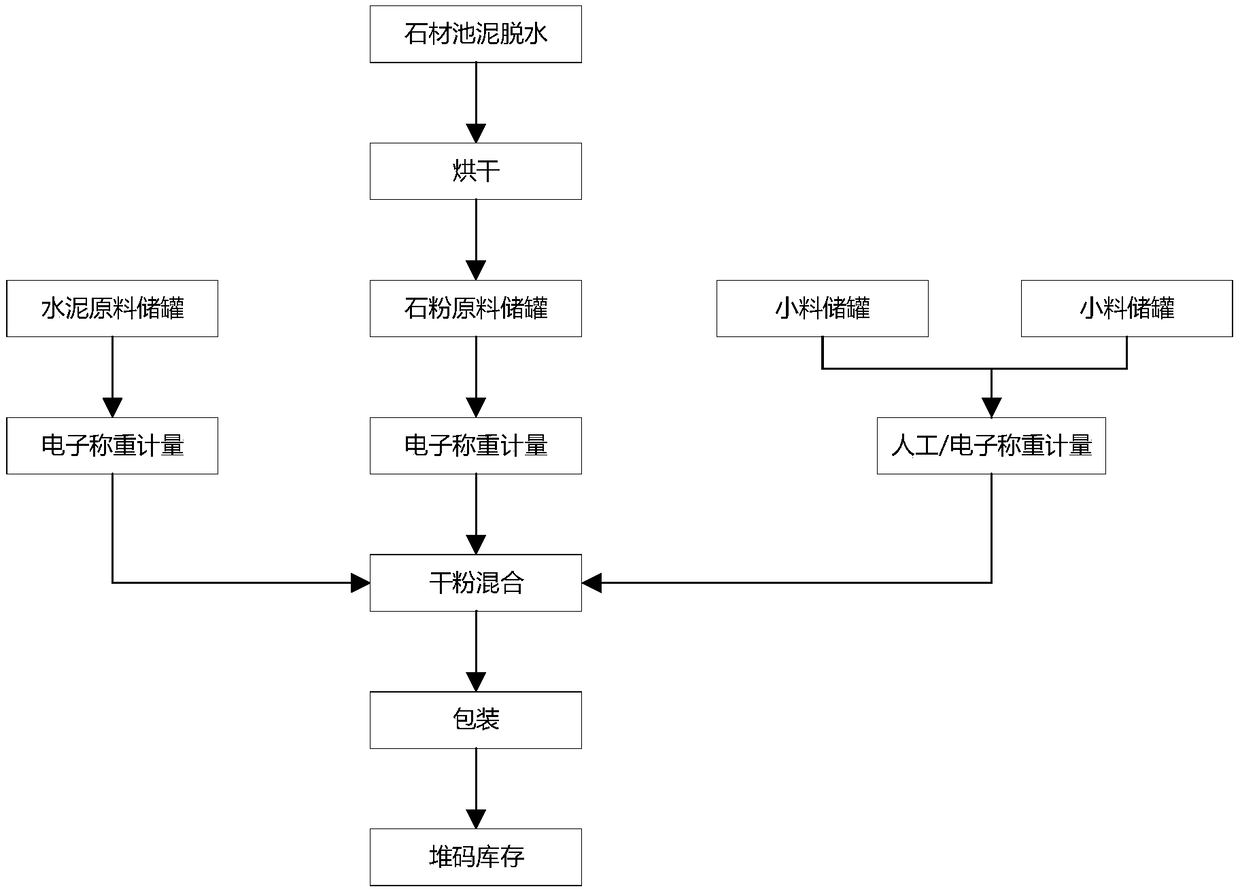

[0038] The preparation method of this marble back glue based on stone material waste slurry comprises the following steps:

[0039] 1) Stone powder raw material preparation: After dehydrating the waste slurry in the stone mud pool, add it to a dryer for continuous drying, and then remove dust, and store the obtained stone powder in a stone powder raw material storage tank for later use;

[0040] 2) Small material preparation: After weighing and measuring redispersible latex powder, preservative, defoamer, cellulose ether additive, thickener, and antifungal agent, mix and stir in a mixer evenly, and the obtained small material Store in small material storage tanks for later use;

[0041] 3) Preparation of back coating: After weighing and measuring stone powder raw materials, small materials, cement and quartz sand, they are mixed and stirred evenly in a mixer to obtain the marble back coating based on stone waste slurry of the aforementioned composition.

[0042] Preferably, i...

Embodiment 1

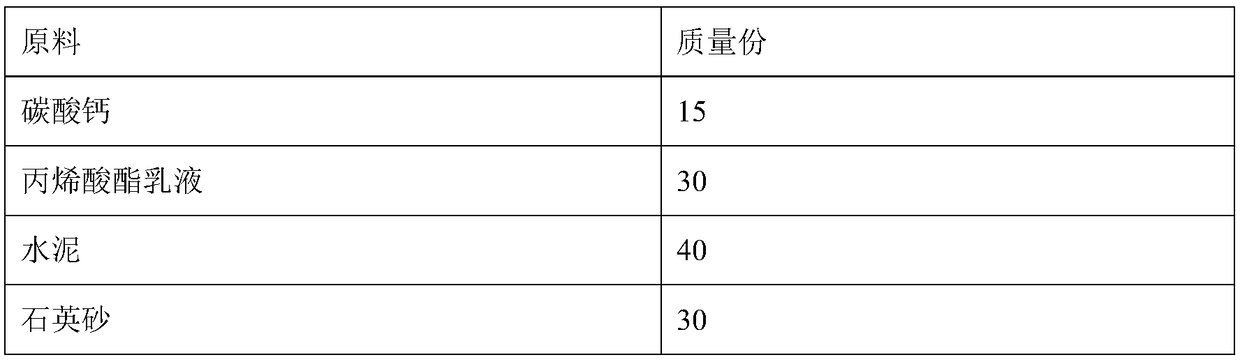

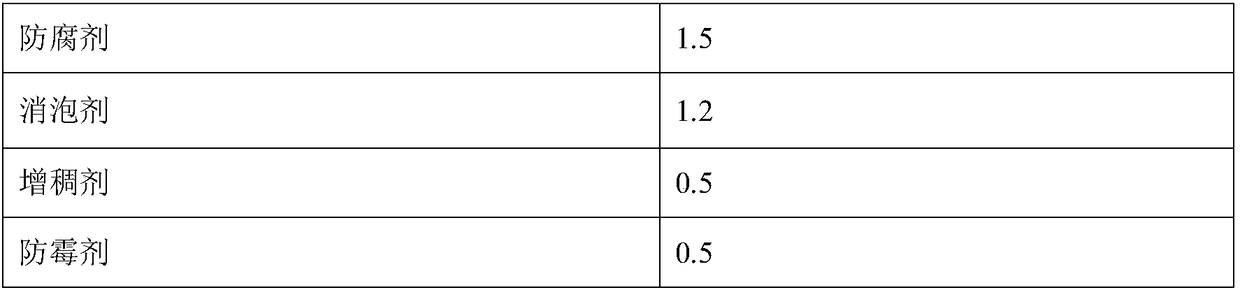

[0050] Example 1 The raw material of the marble back coating glue based on stone waste slurry is composed of the components shown in Table 1.

[0051] Table 1 embodiment 1 is based on the raw material composition of the marble back glue of stone material waste slurry

[0052] raw material

Embodiment 2

[0054] Example 2 The raw materials of the marble back coating glue based on stone waste slurry are composed of the components shown in Table 2.

[0055] Table 2 embodiment 2 is based on the raw material composition of the marble back glue of stone material waste slurry

[0056] raw material

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| flame retardant | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com