Flame-retardant novel material carpet

A new flame retardant material and carpet technology, applied in the field of disposable biodegradable flame retardant new material carpet, can solve the problems of insufficient strength of floor mat, insufficient flame retardant performance, insufficient stiffness, etc. Flammability, reduced risk effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

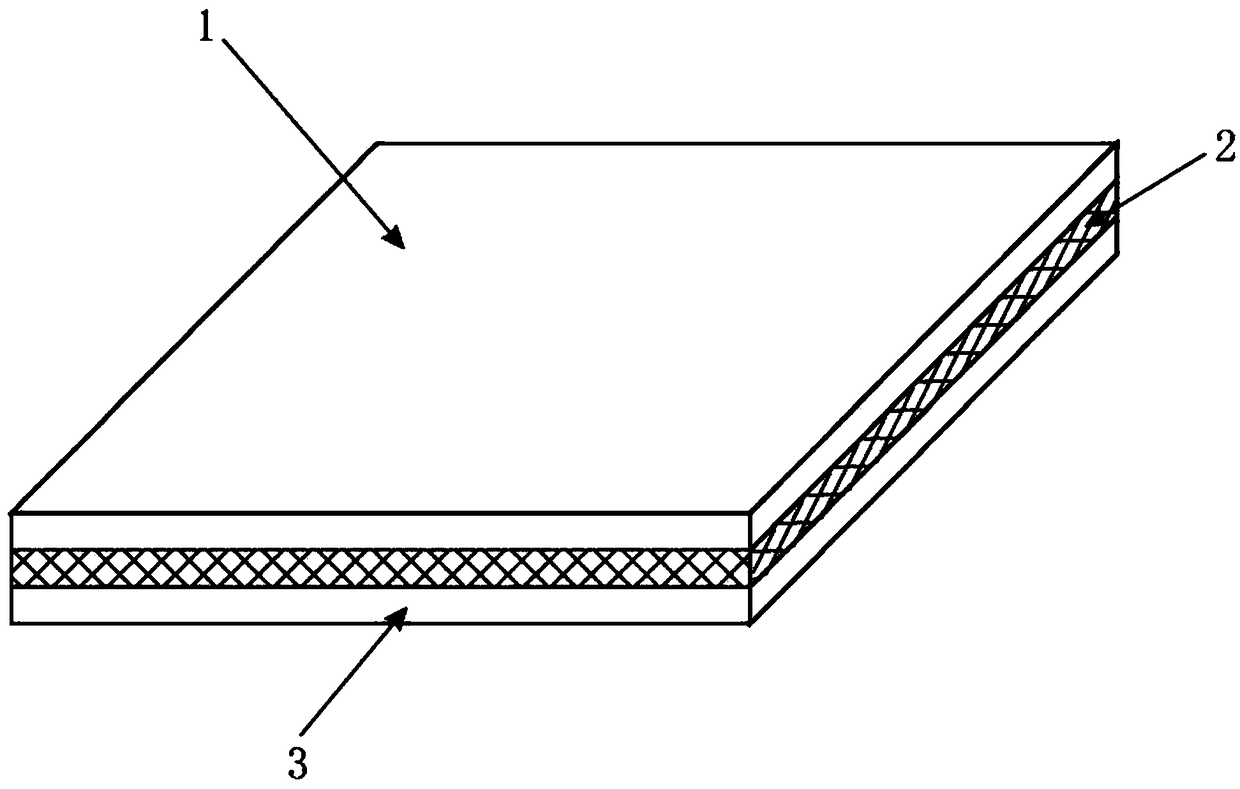

[0015] Such as figure 1 In the flame-retardant new material carpet shown, the polyvinyl alcohol flame-retardant film 1 is bonded with the flame-retardant polyvinyl alcohol glue 2 and the polyvinyl alcohol flame-retardant non-woven fabric 3, and the outer surface of the polyvinyl alcohol flame-retardant non-woven fabric 3 is designed There is a printing layer;

[0016] Wherein, the coating formula of the printing layer is composed of the following raw materials in parts by weight: 30-50 parts of acrylic modified polyurethane emulsion; 10-20 parts of silica sol; 20 parts of water; 10 parts of ethanol; 0.5 parts of leveling agent; 0.5 part of defoamer.

[0017] The thickness of the polyvinyl alcohol flame-retardant film 1 is 30-50 microns, the weight range of the polyvinyl alcohol flame-retardant nonwoven fabric 3 is 45-130 g / square meter, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com