Barrel forming machine

A molding machine and barrel technology, applied in the field of barrels, can solve the problems of misplacement of parts, poor stability, poor processing effect, etc., and achieve the effect of preventing misplacement and misplacement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

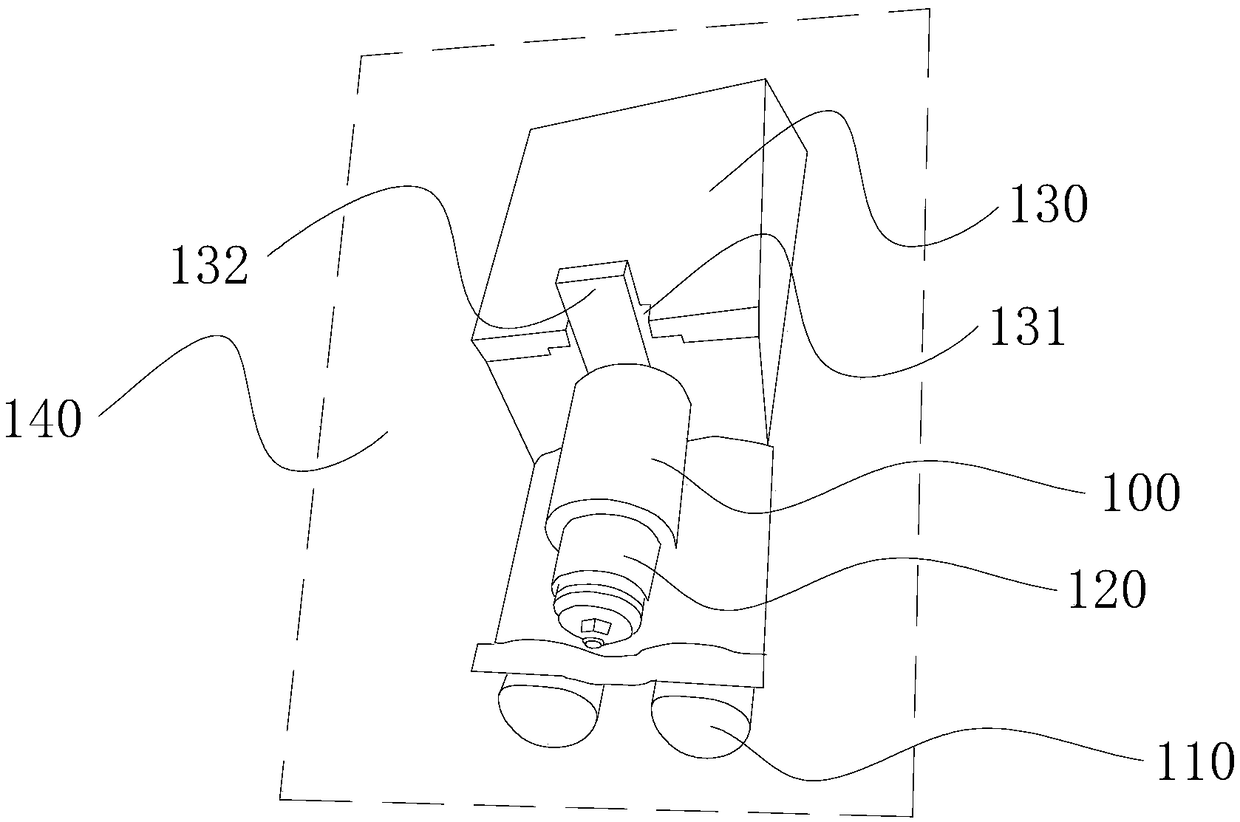

[0013] refer to figure 1 , an embodiment of the present invention provides a barrel forming machine, including a main body, the main body includes a driving wheel 100, a driven wheel 110, and a processing wheel 120 for pressing the sheet into a barrel shape, and the processing wheel 120 Connected to one end of the driving wheel 100, the driven wheel 110 is tightly connected to the lower part of the driving wheel 100 and has a processing gap for the machine piece to be placed between the driving wheel 110 and the processing wheel 120, the cross section of the driving wheel 100 and the driven wheel 110 The sum of the lengths is not greater than the cross-sectional length of the driven wheel 110 .

[0014] In this embodiment, the rotation of the driving wheel 100 is used to drive the driven wheel 110 below it to rotate and the processing wheel 120 connected to one end to rotate. In the processing gap between the two wheels, after one rotation cycle, it will be rolled into the sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com