Cleaning method of steam generator

A technology of steam generator and trolley, which is applied in the directions of cleaning methods and utensils, chemical instruments and methods, cleaning hollow objects, etc., which can solve the problems of inaccessibility of personnel for cleaning and reduction of heat transfer efficiency of pipe walls.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

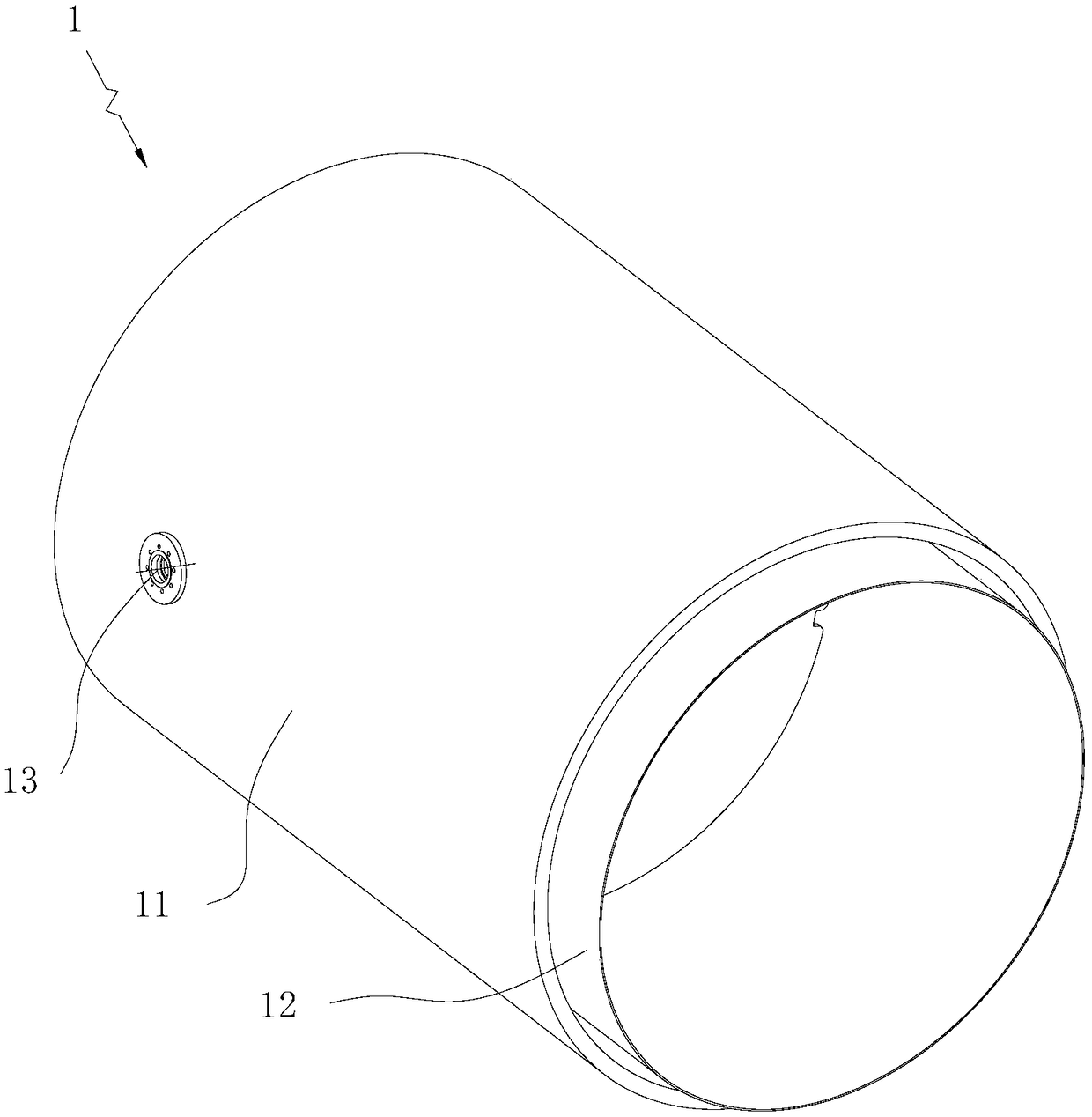

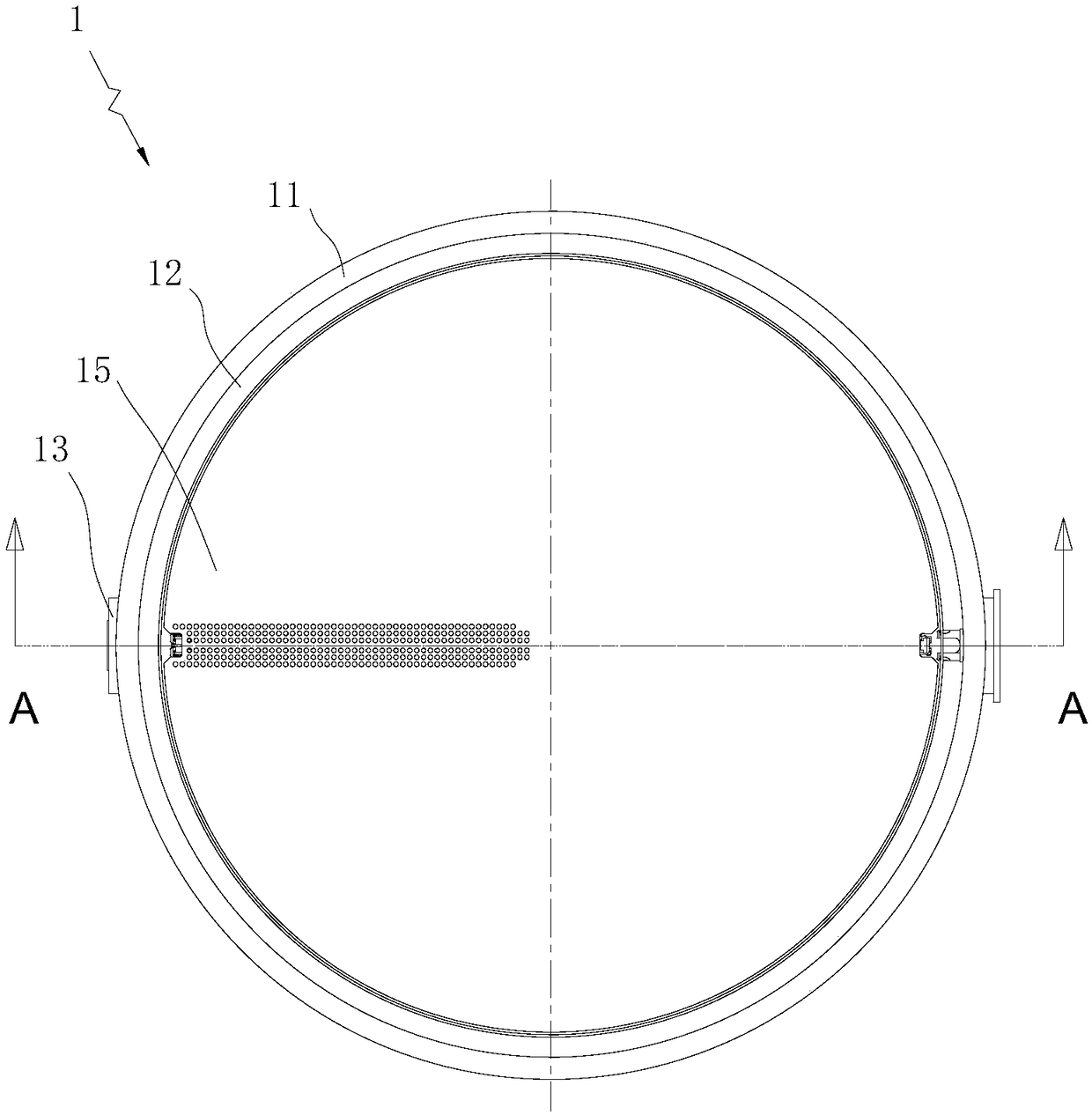

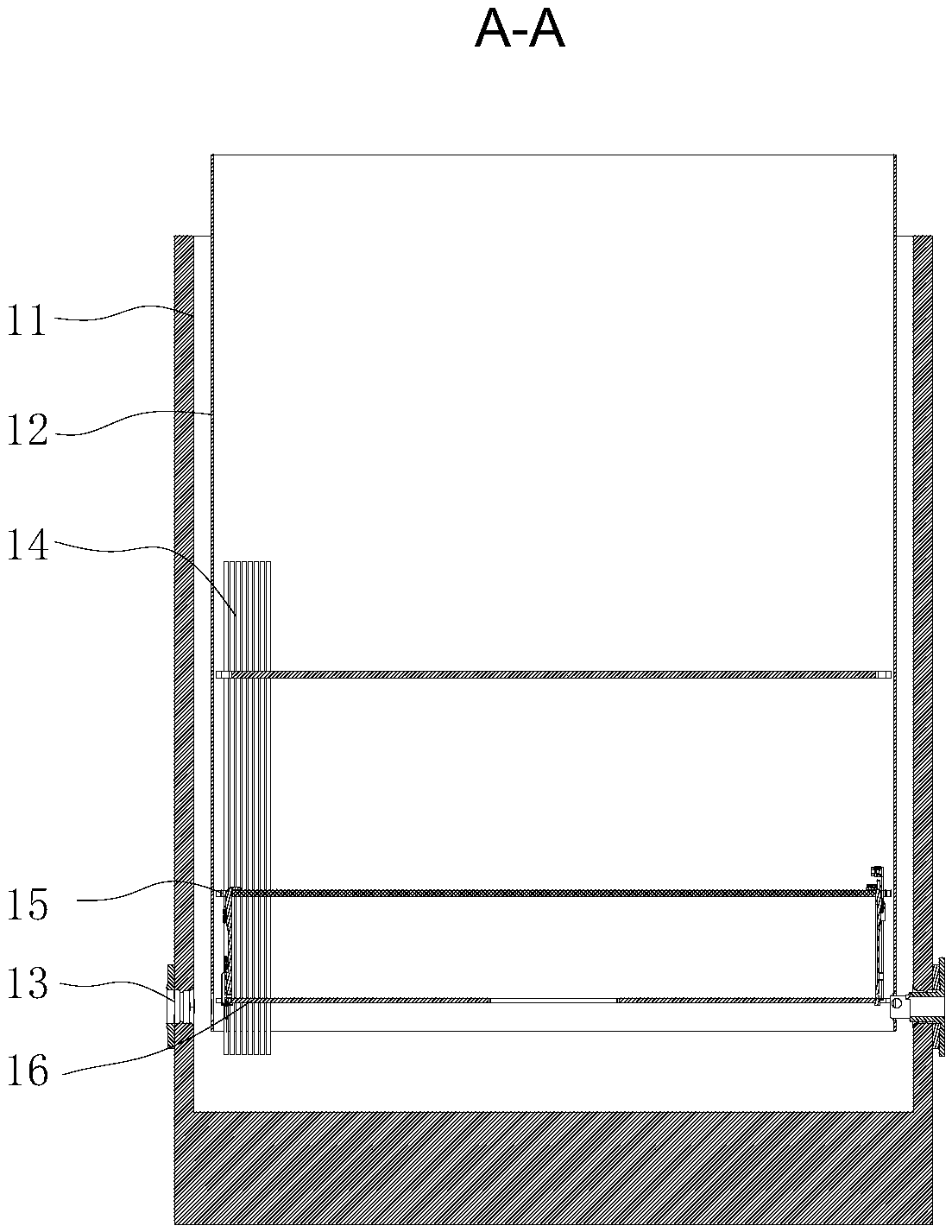

[0053] Furthermore, please also refer to Figure 11 , as a specific embodiment of the cleaning method of the steam generator 1 provided by the present invention, step A specifically includes the following steps:

[0054] A1. Lay out the threading trolley and the tensile cable, place the threading trolley 4 on the first support plate 15 through the hand hole 13 on one side of the steam generator 1, the threading trolley 4 is connected with a tensile cable, and control the threading trolley 4 to move to The hand hole 13 on the other side of the steam generator 1, and take out the threading trolley 4;

[0055] A2. Pull the chain assembly 23 and the washing trolley 3 by the tensile cable to realize the laying of the chain assembly 23 and the washing trolley 3 . Specifically, between the follow-up operations, first use the threading trolley 4 to thread the cables into the first support plate 15 of the steam generator 1. Due to the large volume of the steam generator 1, the chain a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com