Bidirectional low-resistance injector syringe and preparation method thereof

A technology for low-resistance syringes and resistance reduction, applied in the field of syringes, can solve problems such as insurmountable injection resistance and inability to reduce resistance, achieve the effect of small reset force, overcome deformation, and reduce the possibility of pulling deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

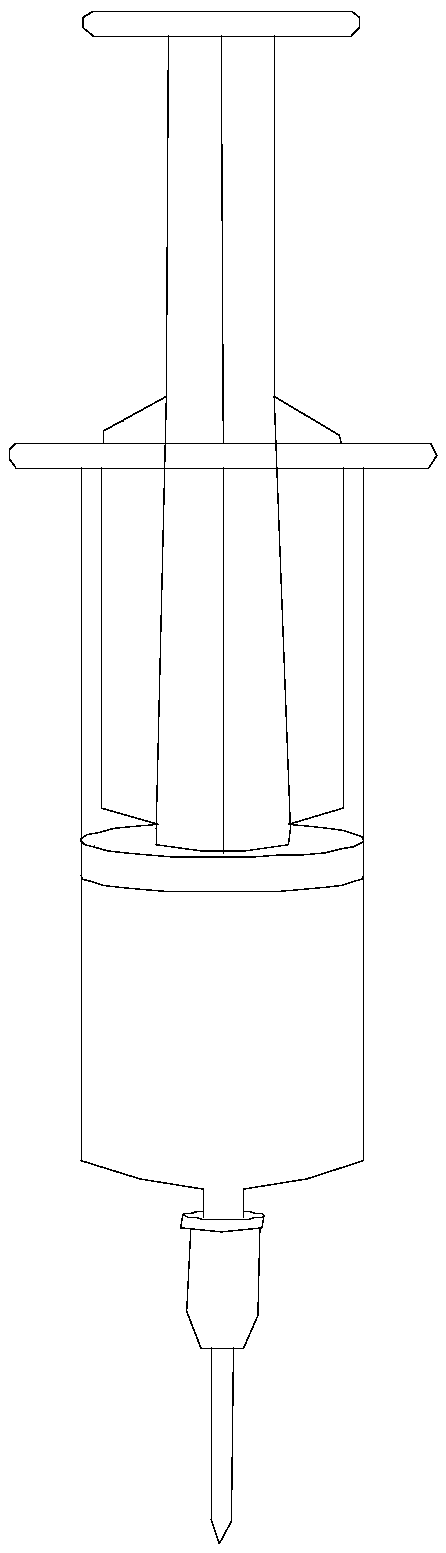

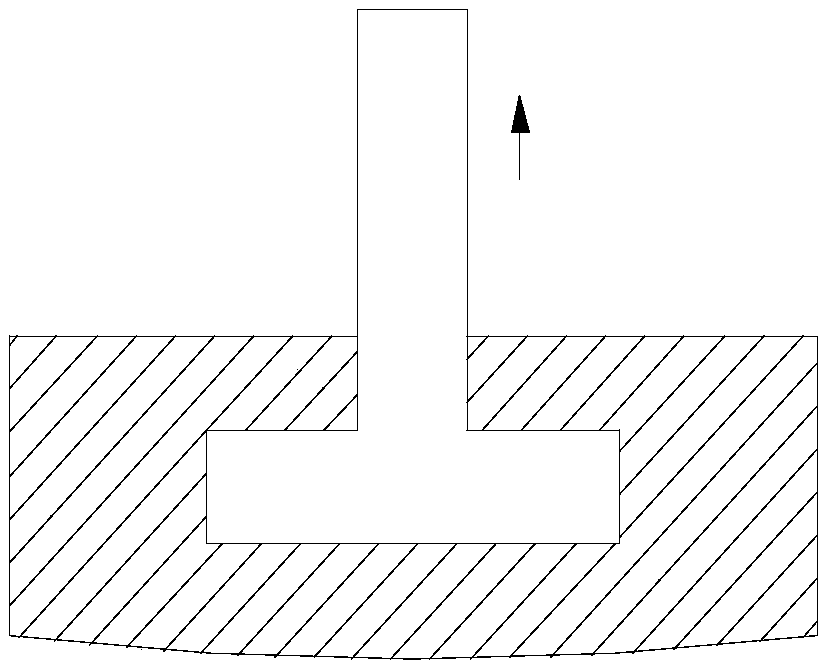

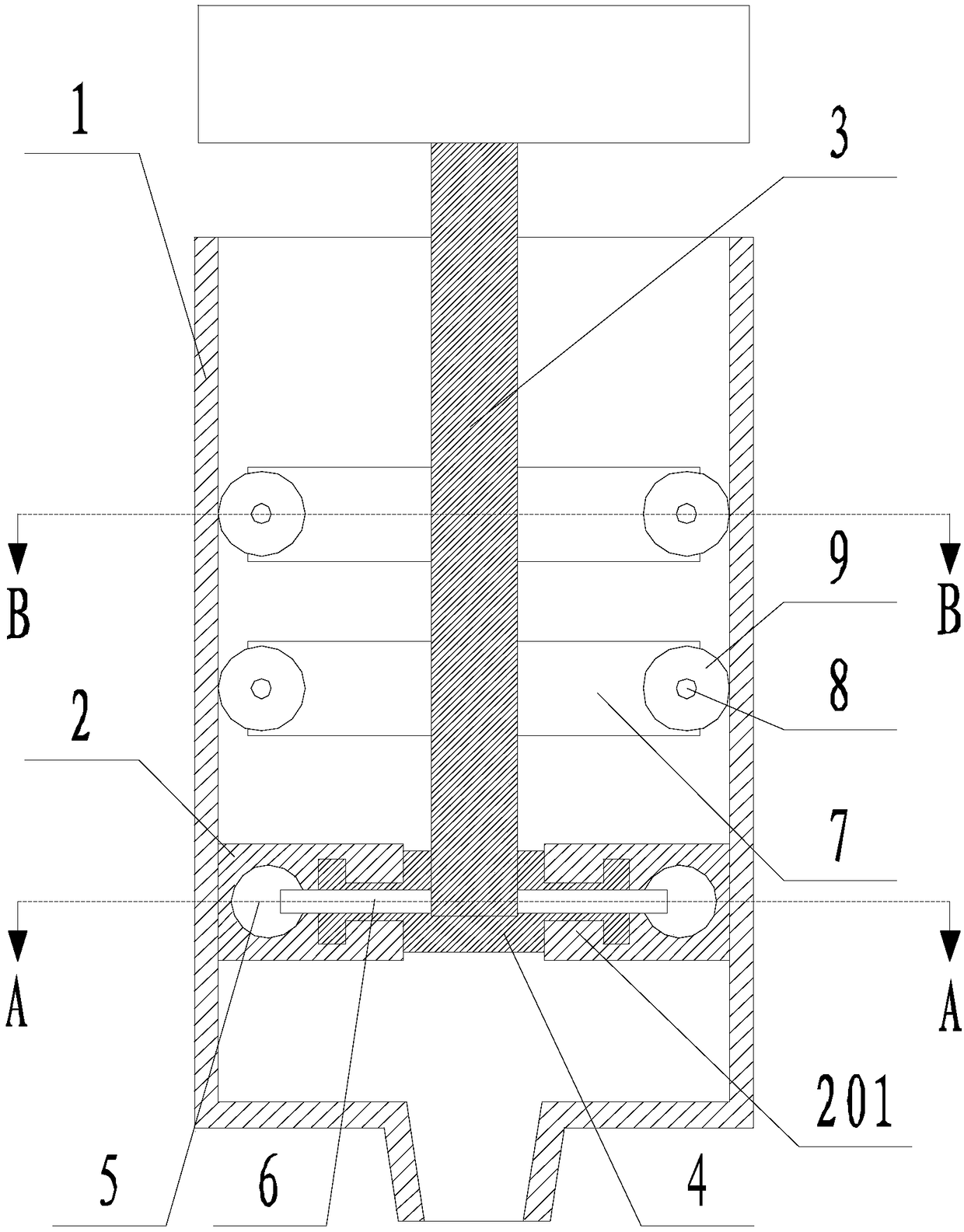

[0042] Such as Figure 3 to Figure 6 A two-way low-resistance syringe shown includes a syringe 1, a piston 2 inside the syringe 1, and a piston rod 3 connected to the piston 2, and one end of the piston rod 3 inside the syringe 1 is fixedly connected to a bearing. The force plate 4, the axis of the piston rod 3 is in line with the axis of the force plate 4; the piston 2 is annular, the piston 2 is set outside the force plate 4, and the outer side of the piston 2 is in contact with the inner wall of the syringe 1 , the ring-shaped piston 2 is provided with a number of ring-shaped evenly distributed steel balls 5, the steel balls 5 are connected to the piston rod 3 through the connecting rod 6 passing through the bearing plate 4, and the steel ball 5 is connected to the inner wall of the syringe 1 The spacing is 15% of the inner diameter of the syringe 1; several groups of drag-reducing components are evenly distributed in the axial direction on the piston rod 3, and each group ...

Embodiment 2

[0045] Such as Figure 3 to Figure 6 In the illustrated bidirectional low-resistance syringe, on the basis of Example 1, ring grooves facing each other are provided on both sides of the force bearing plate 4, and the ring grooves are concentric with the force bearing plate 4. The height of the inner wall of the ring groove is greater than the height of the outer wall, and the inner wall of the ring-shaped piston 2 is provided with a matching portion 201 matching the two ring grooves, and the matching portion 201 is stuck in the ring groove. The bearing plate 4, the piston rod 3, and the syringe 1 are all made of plastic, and the bearing plate 4 and the piston rod 3 are integrally formed; the piston 2 is a rubber stopper. The distance between two adjacent drag-reducing assemblies is 2 cm; the rollers 9 in the drag-reducing assemblies are made of plastic. There are two drag-reducing components. The central angle corresponding to the axes of two adjacent connecting rods 6 on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com