Method and equipment for refining hydrargyrum oxydatum crudum

A technology of Hongshengdan and equipment, applied in the field of Hongshengdan refining and refining equipment, can solve the problems of high refining requirements, complex refining process, low refining product rate, etc., to prevent leakage, improve The effect of safety and quality improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

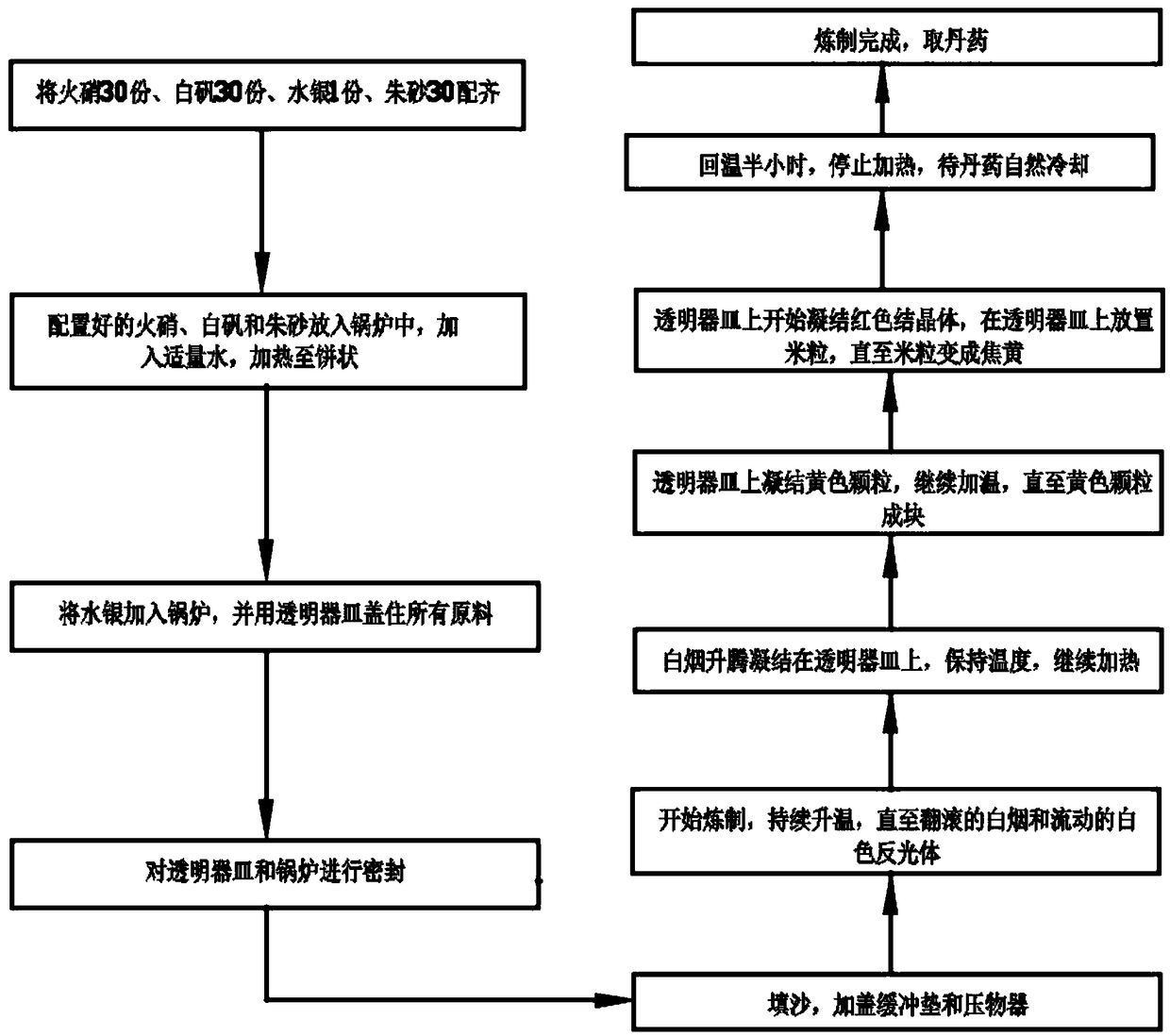

[0036] A method for refining Hongshengdan, comprising the steps of:

[0037] Step 1) Add all raw materials in boiler 2, and cover all raw materials with transparent container 3, also include following four steps before step 1):

[0038] a. Mix 30 parts of fire nitrate, 30 parts of alum, 1 part of mercury, and 30 parts of cinnabar;

[0039] b. Turn on the electric furnace 1 to evaporate the moisture in the transparent vessel 3;

[0040] c. Put the prepared fire salt, alum and cinnabar into the boiler 2, add water, cover the transparent vessel 3, and heat until the water evaporates completely. At this time, the raw materials are also refined into lumps at the bottom of the boiler;

[0041] d. Open the transparent vessel 3, and add 1 part of mercury to the boiler 2.

[0042] Step 2) Seal the contact portion between the transparent vessel 3 and the boiler 2 with the prepared thin mud, which can effectively prevent sand from entering the transparent vessel, contaminate the raw ma...

Embodiment 2

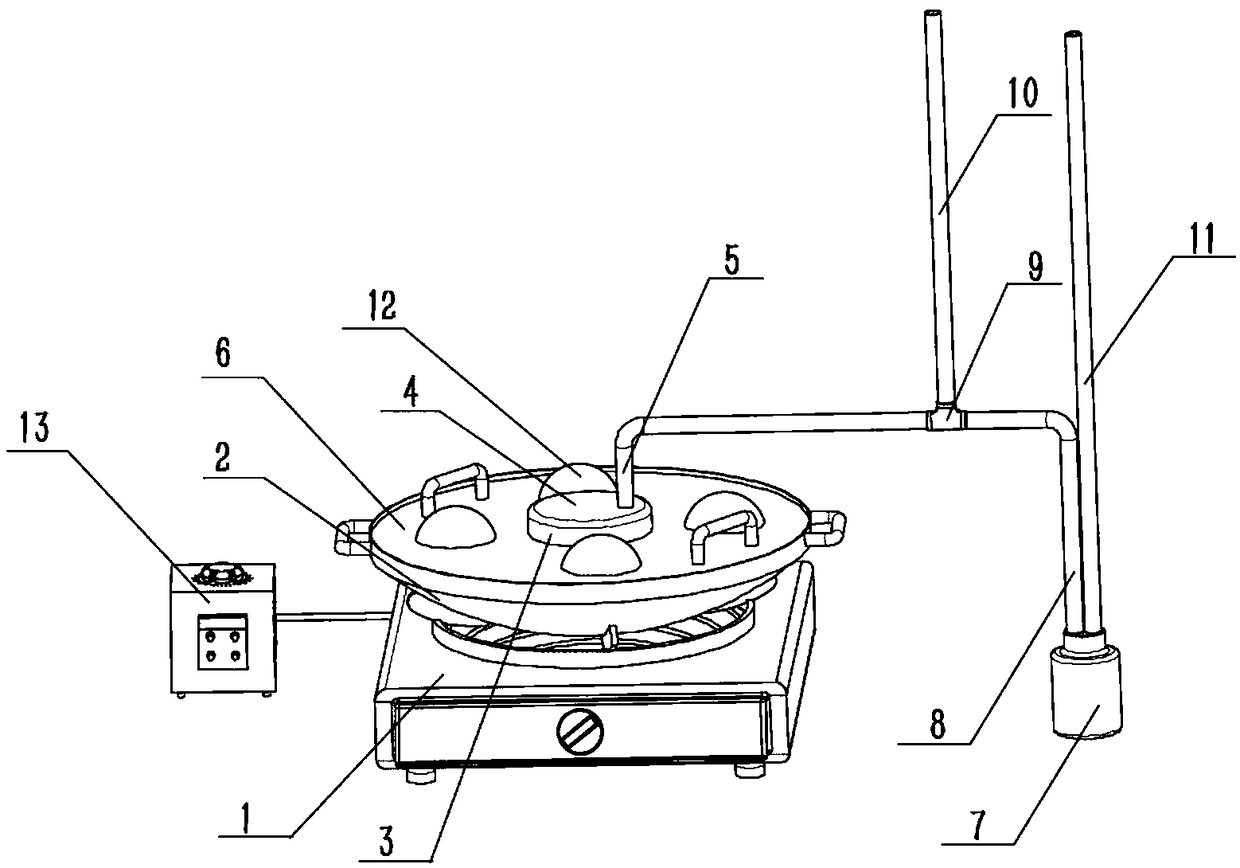

[0060] A kind of equipment used for refining Hongshengdan by the above method: it includes an electric furnace 1 and a boiler 2, the boiler 2 is arranged on the electric furnace 1, the electric furnace 1 is connected with a voltage regulator 13, and the center of the boiler 2 is provided with an inverted transparent container 3, transparent The cover 4 of the container 3 is provided with a total exhaust pipe 5, and a buffer pad 6 is arranged above the boiler 2, and a relief hole for the cover 4 is provided in the middle of the buffer pad 6, and sand is filled between the boiler 2 and the buffer pad 4.

[0061] In the present invention, a transparent container is arranged in the boiler, which is beneficial to observe the refining situation in time during the alchemy process. By embedding the container in the sand, the heating temperature of the entire container can be guaranteed to be uniform, which is beneficial to improve the quality of alchemy. In addition, the buffer pad can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com