Dung and urine removing process for breeding of live pigs

A technology of feces and pigs, which is applied in the field of pig breeding feces and urine removal technology, can solve the problems of poor separation of urine and feces, unsmooth urine discharge, and blockage of feces urination pipes, etc., to maintain the microclimate environment and efficiently It is beneficial to the health of pigs and the effect of reducing odor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

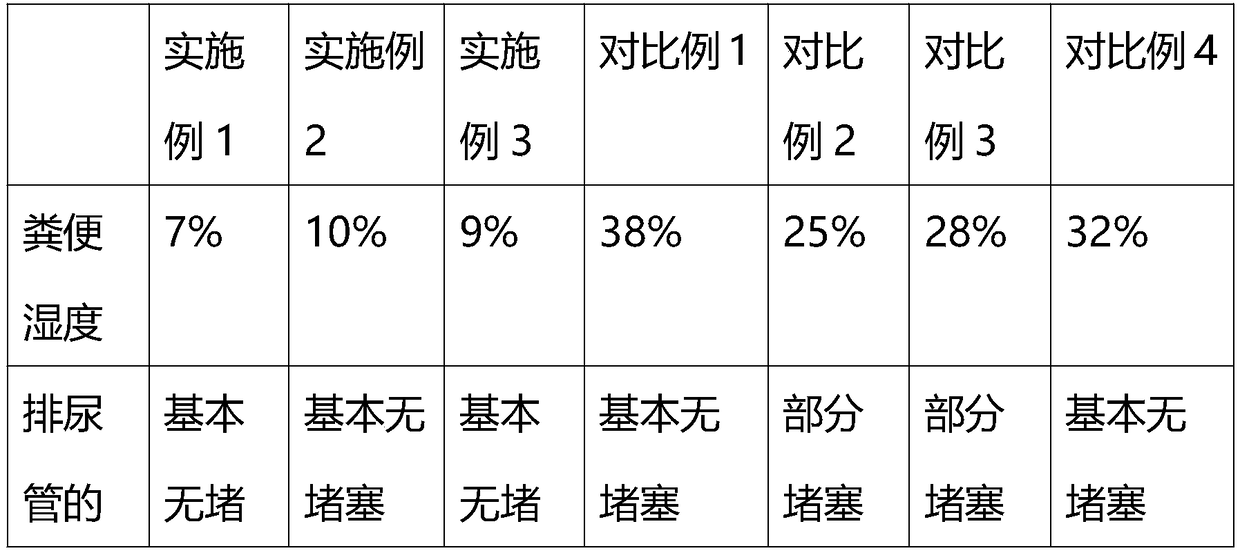

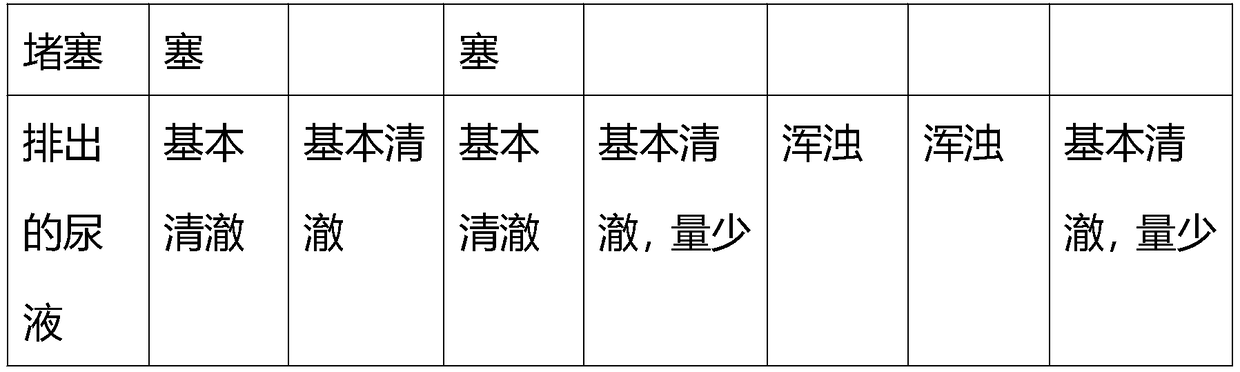

Embodiment 1

[0023] A process for removing excrement and urine from pig breeding, which is characterized in that it includes: adopting a bowl-type water-saving drinking fountain to provide drinking water; using a dung leaking board on the ground surface of the pig house, and a dung tank is arranged on the lower side of the dung leaking board; The groove includes a scraper and a urinary catheter; the scraper slopes from the edge to the middle, with a slope of 35%, forming a funnel shape, and a catheter is provided at the bottom of the center of the scraper, and the catheter guides the dripping water and urine together. Walk; the surface of the scraper is treated with anti-slip agent, and the friction coefficient is 0.85; use the scraper to scrape manure twice a day on the scraper, and keep the scraped dung dry; the contact part of the scraper with the scraper is rubber The width of the material is 2cm; the exported urine is fermented and then used as fertilizer; the scraped pig manure does n...

Embodiment 2

[0027] A process for removing excrement and urine from pig breeding, which is characterized in that it includes: adopting a bowl-type water-saving drinking fountain to provide drinking water; using a dung leaking board on the ground surface of the pig house, and a dung tank is arranged on the lower side of the dung leaking board; The groove includes a scraper and a urinary catheter; the scraper slopes from the edge to the middle, with a slope of 25%, forming a funnel shape, and a catheter is provided at the bottom of the center of the scraper, and the catheter guides the dripping water and urine together. Walk; the surface of the scraper is treated with anti-slip agent, and the friction coefficient is 0.8; use the manure scraper to scrape manure twice a day on the scraper, and keep the scraped manure dry; the contact part of the scraper with the scraper is rubber The width of the material is 3cm; the exported urine is fermented and then used as fertilizer; the scraped pig manur...

Embodiment 3

[0031] A process for removing excrement and urine from pig breeding, which is characterized in that it includes: adopting a bowl-type water-saving drinking fountain to provide drinking water; using a dung leaking board on the ground surface of the pig house, and a dung tank is arranged on the lower side of the dung leaking board; The groove includes a scraper and a urinary catheter; the scraper slopes from the edge to the middle, with a slope of 45%, forming a funnel shape, and a catheter is provided at the bottom of the center of the scraper, and the catheter guides the dripping water and urine together. Walk; the surface of the scraper is treated with anti-slip agent, and the friction coefficient is 0.9; use the manure scraper to scrape manure twice a day on the scraper, and keep the scraped manure dry; the contact part of the scraper with the scraper is rubber The width of the material is 1cm; the exported urine is fermented and then used as fertilizer; the scraped pig manur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com