Automatic brushing machine for interior wall paint

A technology for interior wall paint and brushing machine, which is applied in the direction of coating, devices for coating liquid on the surface, construction, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below in conjunction with accompanying drawing embodiment:

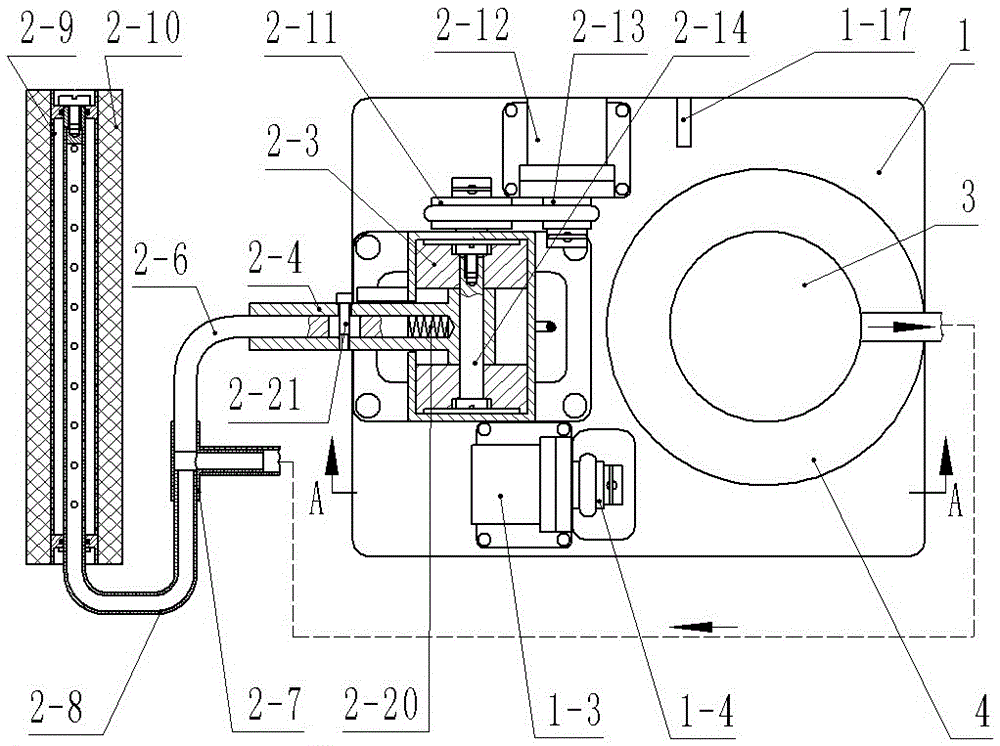

[0018] Such as figure 1 and image 3 The shown automatic brushing machine for interior wall paint includes a rolling brush head 2-10, the rolling brush head 2-10 of this embodiment is made of sponge, and the rolling brush head 2-10 is set on the paint delivery mandrel; The first power machine of the present embodiment is a stepper motor 1-3, the second power machine is a stepper motor 2-12, and the power pump is a vane pump 3; a front end is equipped with a proximity switch 1-17 by the stepper motor 1-3 Driven trolley; the trolley has a rectangular car panel 1 and two pairs of road wheels mounted on the bottom of the car panel 1, the two pairs of road wheels are a pair of front road wheels 1-1 and a pair of rear road wheels 1-8, two front road wheels Wheels 1-1 are all installed on the front wheel support by front wheel shaft 1-2, and the front wheel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com