Susceptor for wafer

A chip and base technology, applied in discharge tubes, electrical components, circuits, etc., can solve problems such as inability to ensure insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

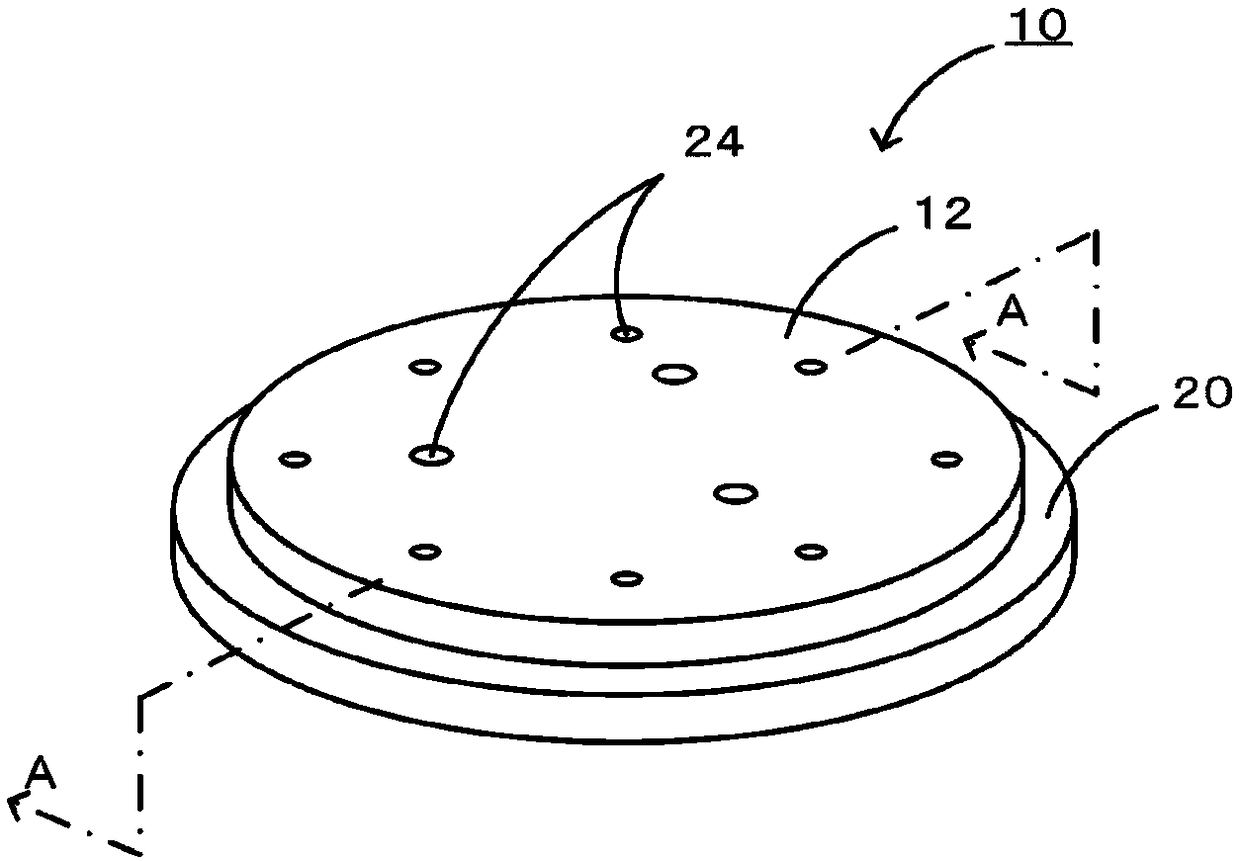

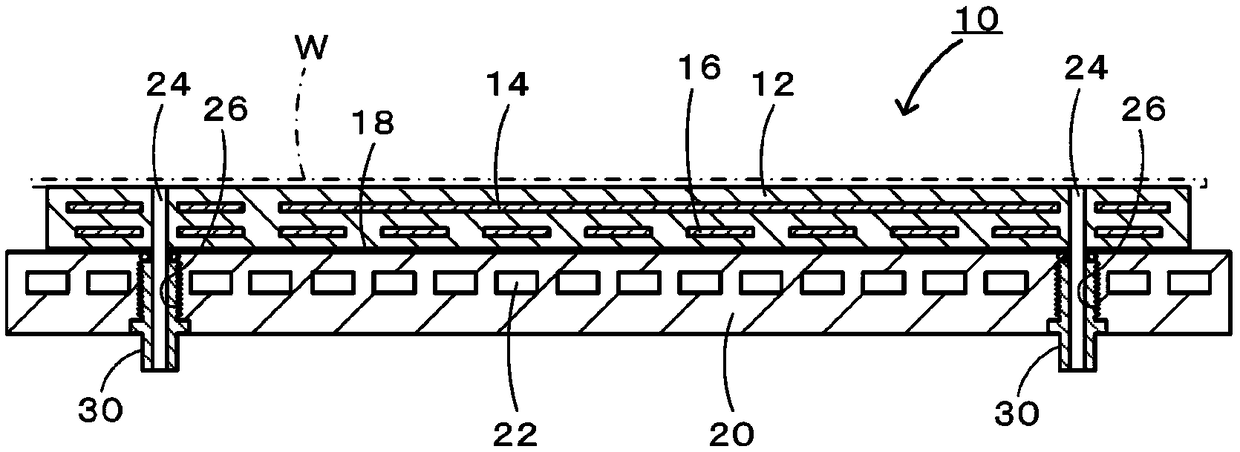

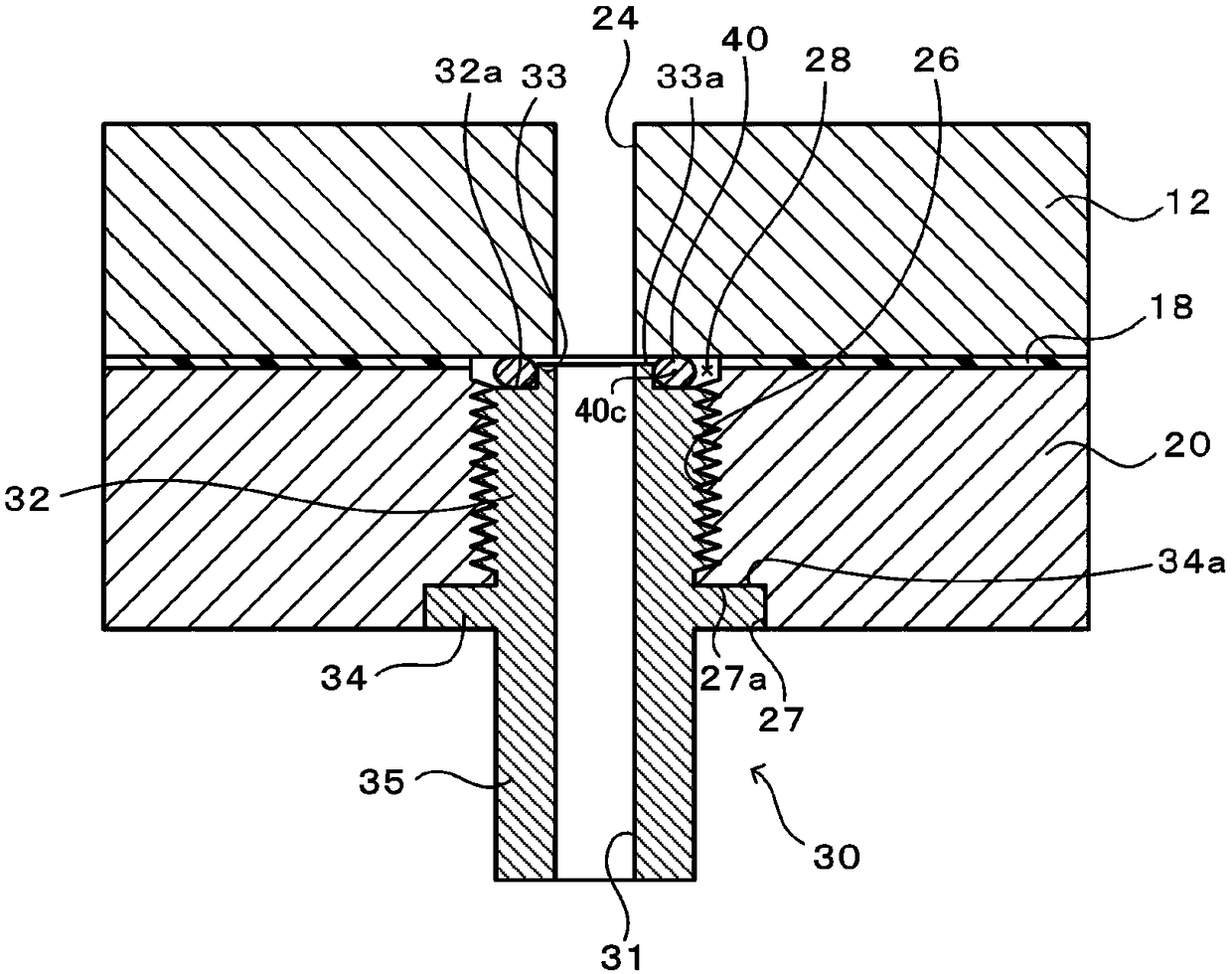

[0028] Embodiments of the present invention will be described based on the drawings. figure 1 It is a perspective view of an electrostatic chuck 10 as an example of the wafer susceptor of the present invention, figure 2 yes figure 1 The A-A sectional view of image 3 yes figure 2 An enlarged view of the periphery of the insulating tube 30, Figure 4 is an enlarged perspective view of the annular protrusion 33, Figure 5 It is a sectional view showing how the insulating tube 30 is attached to the screw hole 26 . In addition, in image 3 and Figure 5 In the figure, the electrostatic electrode 14, the resistance heating element 16, and the refrigerant passage 22 are omitted.

[0029] The electrostatic chuck 10 includes a flat plate 12, a cooling plate 20, a plurality of through holes 24, and an insulating tube 30 inserted into and fixed to each of the through holes 24 (refer to figure 2 , image 3 ), the upper surface of the flat plate 12 serves as a mounting surface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com