Blade, having different thicknesses, for the lining of a mold used for vulcanizing a tire

An in-mold and thin-plate technology, which is applied to home appliances, other home appliances, tires, etc., can solve problems such as inability to optimize tire performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

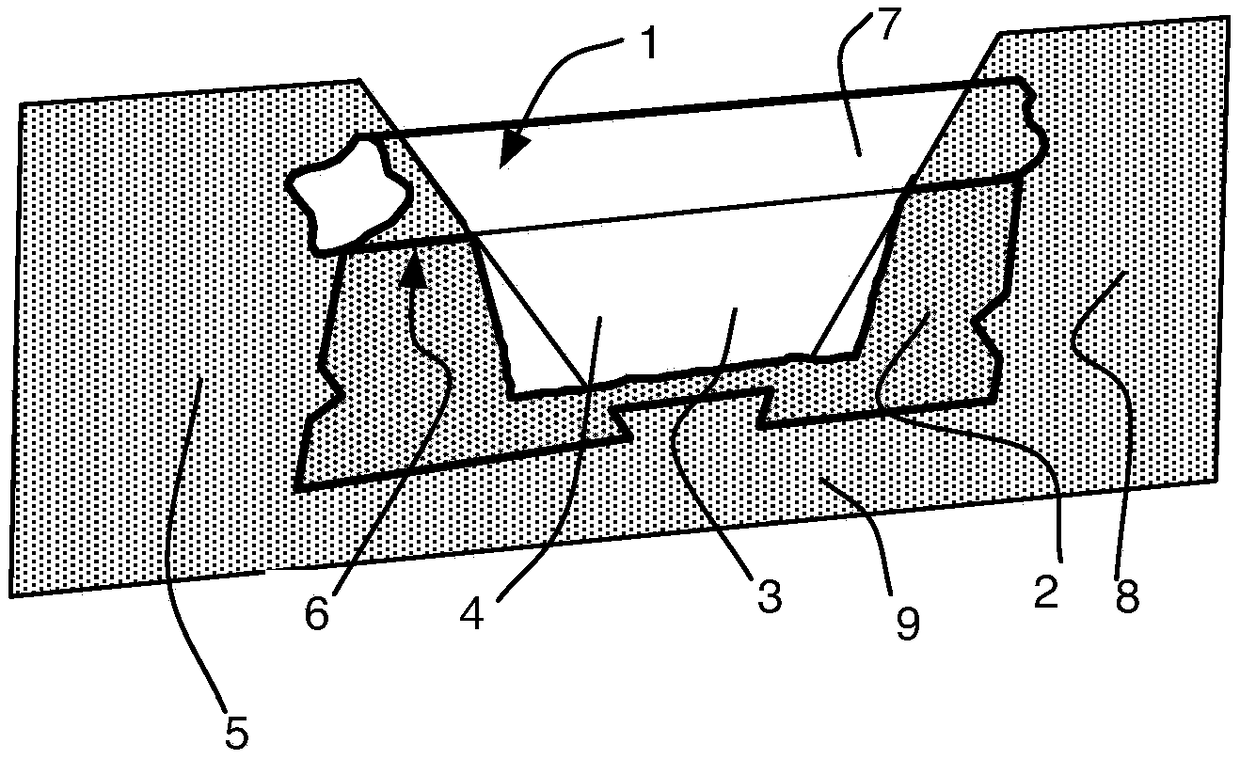

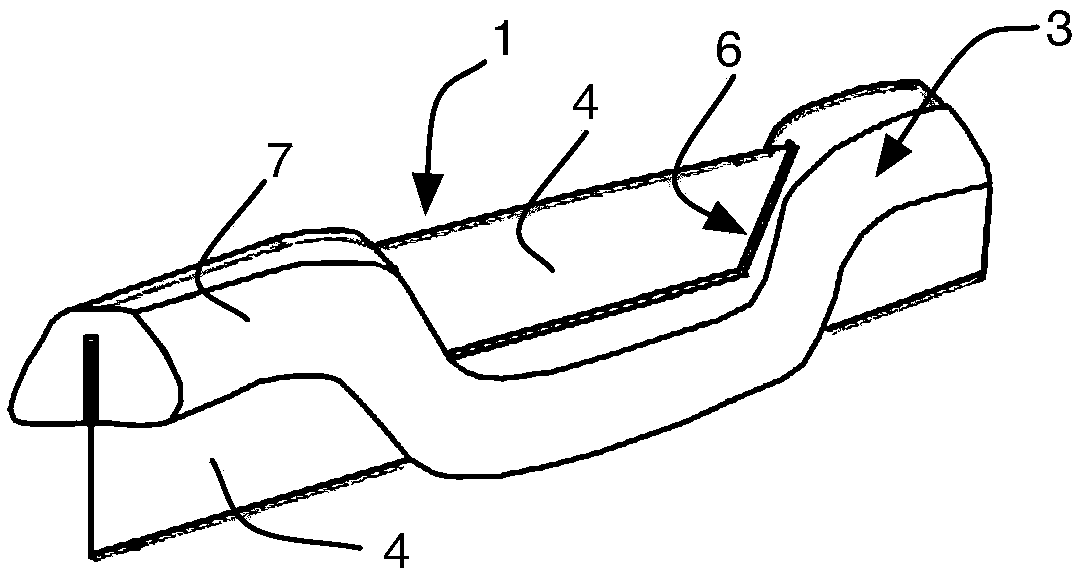

[0025] figure 1 An exemplary embodiment of a sheet 1 of a mold insert intended for tire tread vulcanization is shown. The main body 5, into which the thin plate is inserted, is shown in section. It can be seen that the thin plate extends from one side of the body 5 to the other, and it can be seen that a section called the molded part 3 is hollow between the two strips 8 of the body 5 . The part of the sheet housed in the strip 8 and the base 9 of the body 5 forms the fixed part 2 . The molding portion 3 is configured to mold at least one cut in the tire tread. The fixing part 2 is configured to hold the sheet 1 in the body 5 of the insert.

[0026] As shown, the molded part 3 includes a protrusion 7 and a thin part 4 . Depending on the embodiment, the thin portion may have an average thickness between 0.1 mm and 0.4 mm, the thinnest area can even be as thin as 0.05 mm. Advantageously, this thickness is obtained by a forming method such as pressing.

[0027] exist fig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com