Liquid crystal displaying panel

A liquid crystal display panel and substrate technology, which is applied in nonlinear optics, instruments, optics, etc., can solve the problems of light leakage at the edge of the panel, and achieve the effects of reducing phase delay, reducing stress, and improving light leakage at the edge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

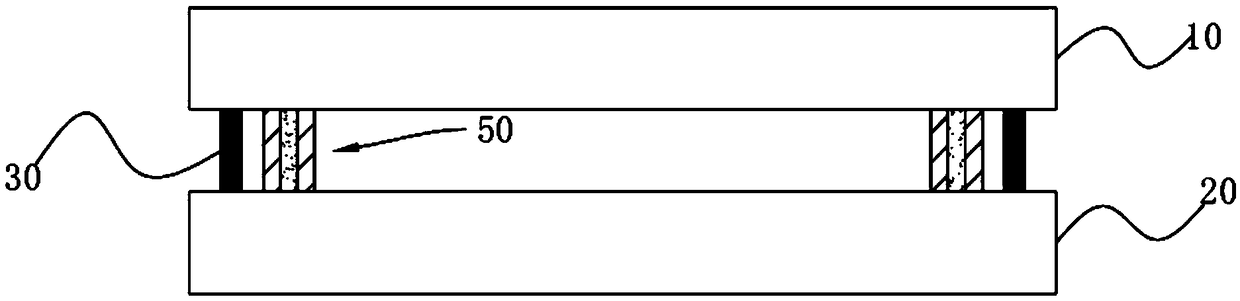

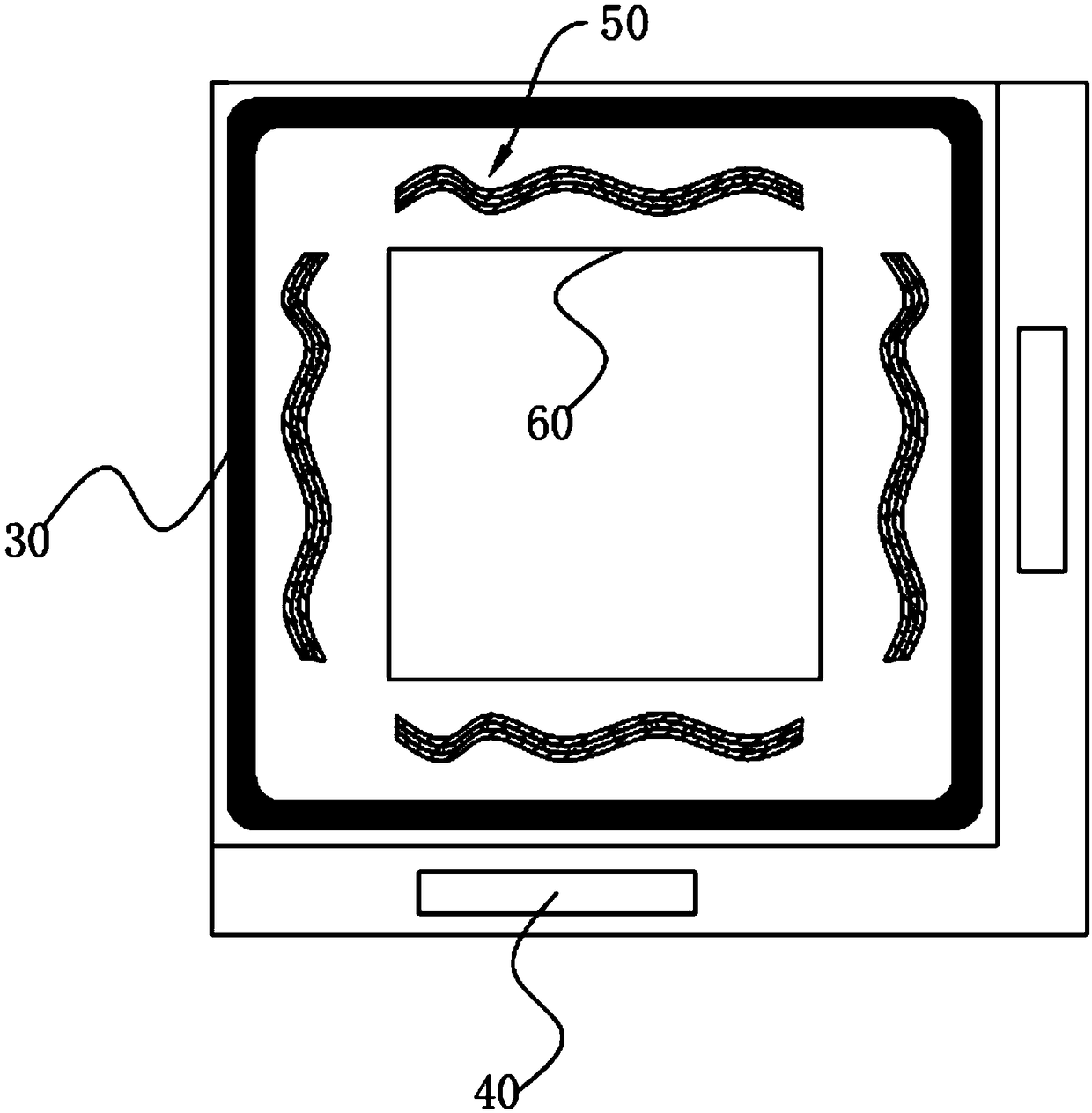

[0031] A liquid crystal display panel, such as figure 1 As shown, the liquid crystal display panel includes a driver chip 40, a color filter substrate 10, a thin film transistor substrate 20, and a sealant 30 disposed between the color filter substrate 10 and the thin film transistor substrate 20. The sealant 30 A liquid crystal layer (not shown in the figure) is disposed in the sealed cavity formed with the color filter substrate 10 and the thin film transistor substrate 20 .

[0032] Among them, such as figure 1 with figure 2 As shown, an elastic buffer structure 50 distributed around the display area 60 is also provided between the color filter substrate 10 and the thin film transistor substrate 20 , and the elastic buffer structure 50 is located inside the sealant 30 .

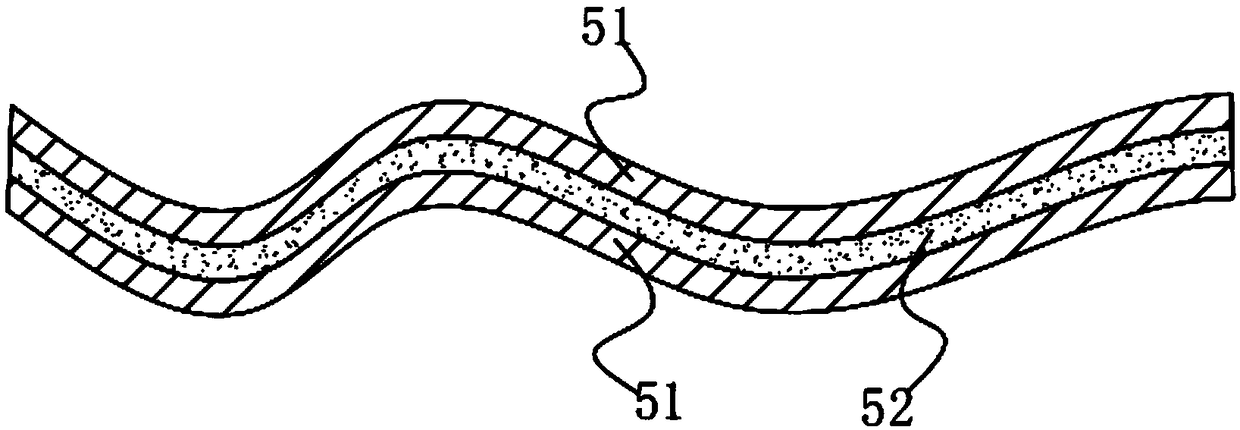

[0033] Specifically, the elastic buffer structure 50 includes a first elastic member fixedly arranged on the color filter substrate 10 and a second elastic member fixedly arranged on the thin film trans...

Embodiment 2

[0044] A liquid crystal display panel, such as Figure 4 As shown, it differs from Embodiment 1 only in that the number of second elastic strips 52 included in the second elastic member is different.

[0045] Specifically, the second elastic member includes at least two second elastic strips 52 arranged in parallel.

[0046] It should be noted, Figure 4 2 only illustrates the case where the second elastic member includes two second elastic strips 52 , in a specific implementation, the second elastic member may also include three, four or more second elastic strips 52 .

Embodiment 3

[0048] A liquid crystal display panel, such as Figure 5 As shown, it differs from Embodiment 1 only in that the number of second elastic strips 52 included in the second elastic member and the number of first elastic strips 51 included in the first elastic member are different.

[0049] Specifically, the second elastic member includes at least two second elastic strips 52 arranged in parallel and spaced apart, and the first elastic member includes a first elastic strip 51 .

[0050] Wherein, the shape of the gap between the adjacent second elastic strips 52 is adapted to the shape of the first elastic piece, and when the first elastic piece engages with the second elastic piece, the first elastic piece The elastic piece is located in the gap between the adjacent second elastic strips 52 .

[0051] It should be noted, Figure 5 2 only illustrates the case where the second elastic member includes two second elastic strips 52 , in a specific implementation, the second elastic ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com