A kind of film of depolarization beam combiner and design method thereof

A design method and depolarization technology, which is applied in the field of lasers, can solve the problem of inability to obtain high reflectivity, transmittance depolarization effect, large polarization separation of P-polarized light and S-polarized light, and inability to take both anti-reflection and high reflection into consideration. and other problems, to achieve good depolarization effect and spectral characteristics, eliminate polarization separation, and excellent spectral characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

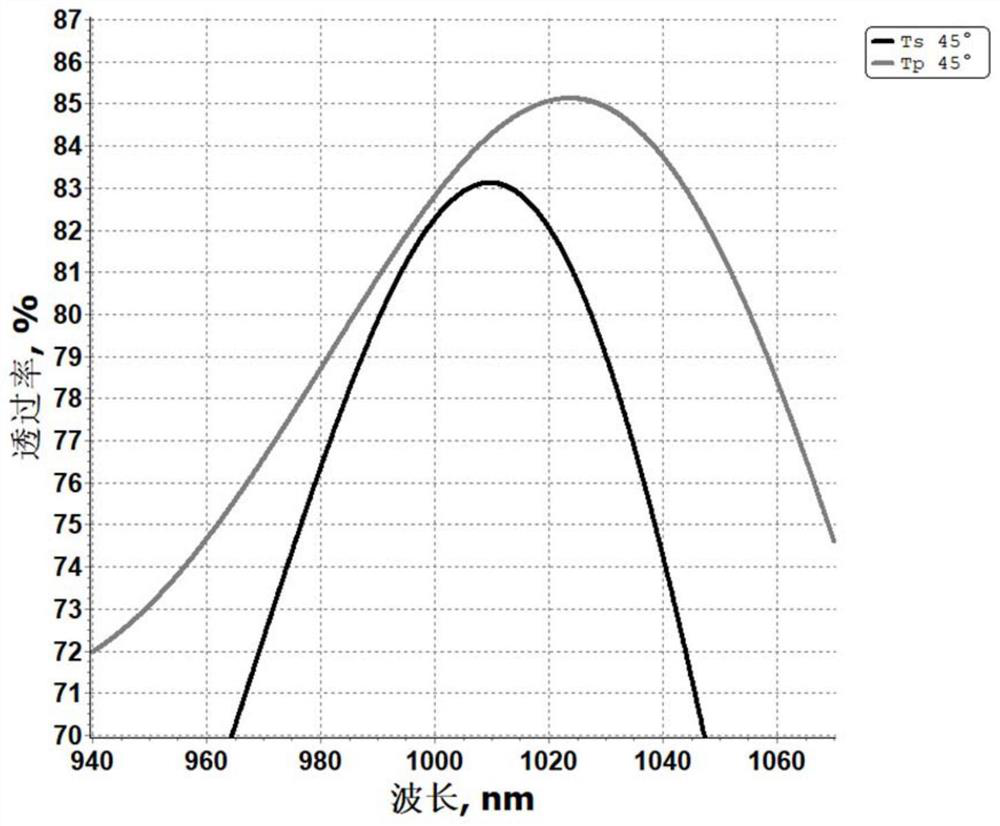

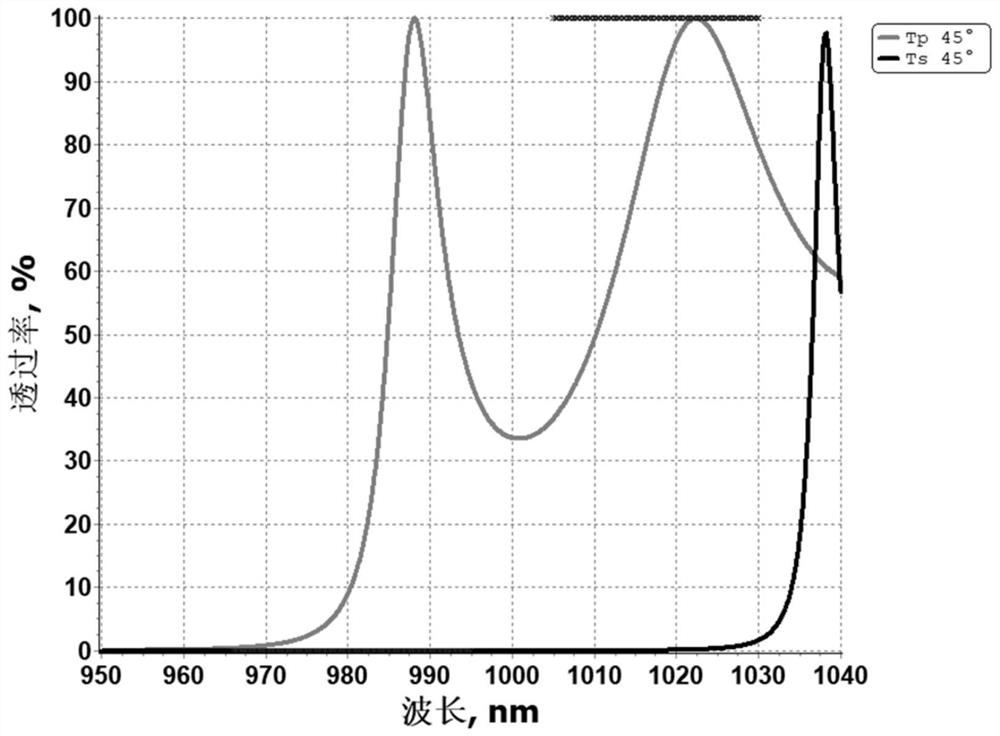

[0065] This embodiment provides a 45-degree near-infrared depolarization beam combiner film and a design method. Its combined laser beam wavelength: λ A 976nm, λ B It is 1010nm, that is, it needs to meet the high reflection of P-polarized light and S-polarized light at 976nm, and the high transmission of P-polarized light and S-polarized light at 1010nm, and eliminate the polarization separation of P-polarized light and S-polarized light. image 3 Shown is the regular high-reflection film: Sub|(HL)^20|Air transmittance spectrum, it can be seen that the initial film system has a large degree of polarization separation, even through optimization, it is difficult to completely eliminate polarization. Therefore, more effective depolarization design methods are needed.

[0066] The specific design method includes the following steps:

[0067] 45-degree near-infrared depolarization beam combiner film structure, such as figure 1 As shown, it includes a substrate 1 and a first thi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com