Centralized purification and quality-dividing water supply system for medicinal water

A quality-based water supply and medical technology, applied in the field of water treatment, can solve the problems of multiple equipment, large investment, unfavorable comprehensive utilization of water resources, etc., and achieve the effect of realizing utilization, reducing operating costs and management costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

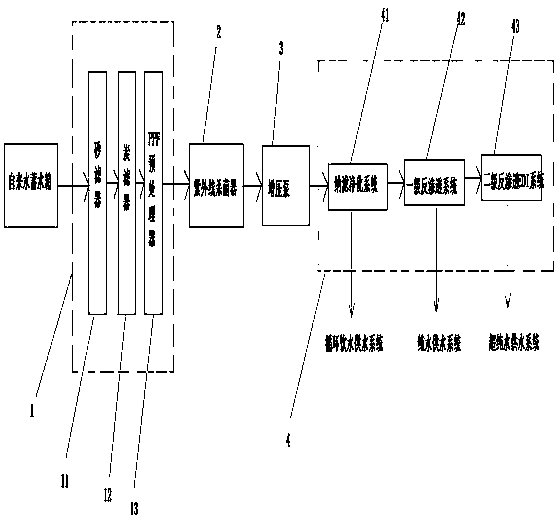

[0014] refer to figure 1 , a medical water centralized purification and quality-based water supply system, said system sequentially includes a multi-stage pretreatment device 1, an ultraviolet sterilizer 2, a booster pump 3 and a three-stage purification system 4, wherein the water inflow of the multi-stage pretreatment device 1 Terminate with tap water.

[0015] Specifically, the three-level purification system 4 includes a first-level purification system 41, a second-level purification system 42, and a third-level purification system 43 connected in sequence, and the first-level purification system 41 is a nanofiltration purification system. The tap water sent by the booster pump 3 is used to purify drinking water for production.

[0016] The second-level purification system 42 is a first-level reverse osmosis system, which connects drinking water p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com