High-pressure-resistant tee forming machine capable of improving yield

A high-pressure-resistant, forming machine technology, applied in the field of high-pressure-resistant three-way forming machines, can solve the problems of lower yield, insufficient water pressure of U-shaped pipes, water leakage, etc., and achieve the effect of increasing yield and avoiding internal water pressure loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

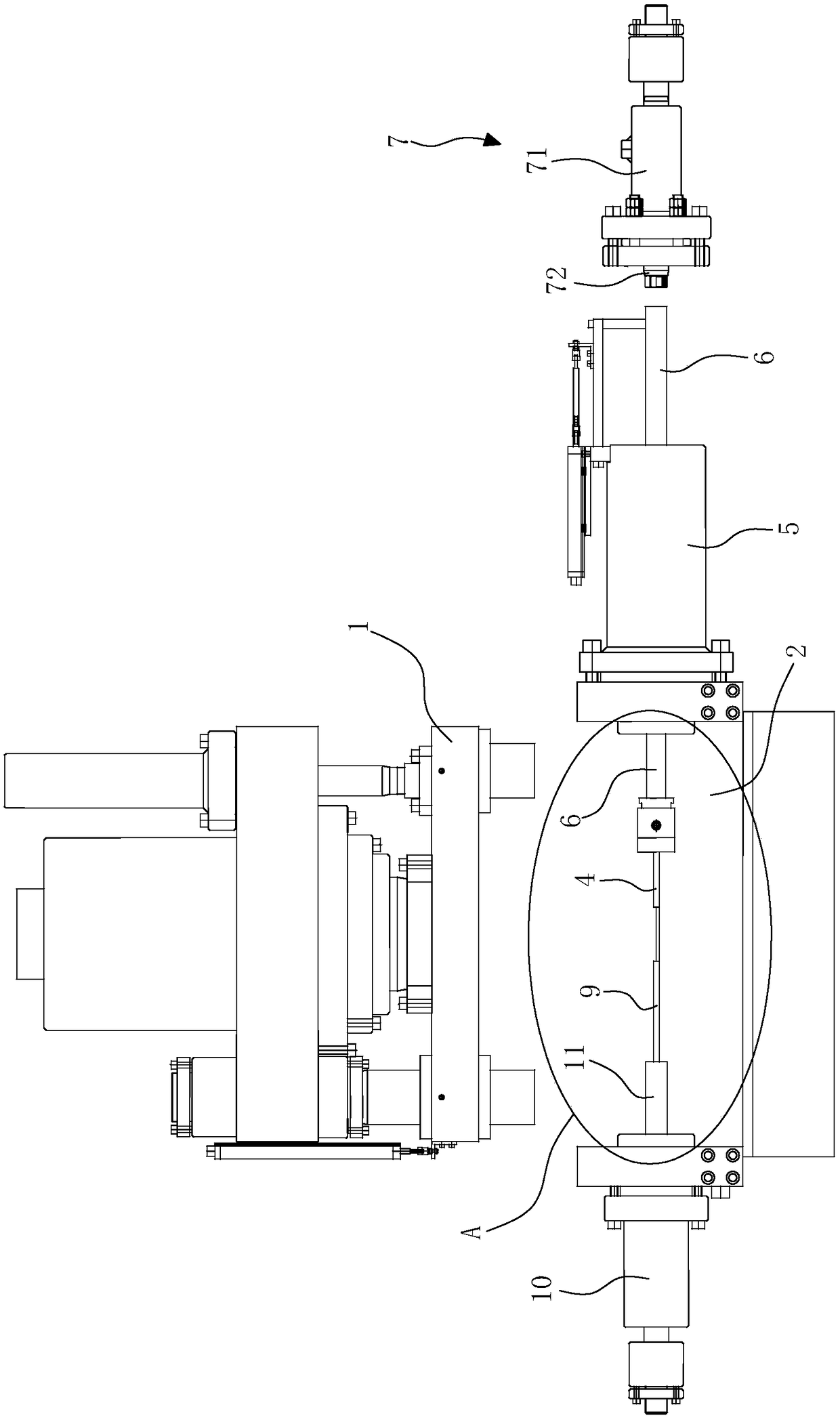

[0029] Embodiment 1. The telescopic anti-retraction device 7 stops the retreat oil cylinder 71. The retreat oil cylinder 71 is arranged at the tail of the main piston rod 6. The retreat stop piston rod 72 of the stop-retreat oil cylinder 71 is facing the tail end of the main piston rod 6 to prevent the main piston rod 6 from The backward movement is generated, which is achieved by the anti-retraction piston rod 72 against the end of the main piston rod 6. This structure will not affect the secondary forward movement of the main piston rod 6. After the production is completed, the anti-retraction piston rod 72 will retreat Reset, then the main piston rod 6 also retreats and resets.

Embodiment 2

[0030] Embodiment 2: The telescopic anti-retraction device 7 is a first electromagnetic telescopic device 73, and the first electromagnetic telescopic device 73 is installed above the tail end of the main piston rod 6. When the main piston rod 6 is pushed forward for the first time, the first electromagnetic telescopic device 73 starts, stretches out the electromagnetic piston rod 74, and blocks the end of the main piston rod 6 to prevent the main piston rod 6 from retreating. This structure will not affect the secondary forward action of the main piston rod 6. 74 is retracted and reset, and the main piston rod 6 is also retracted subsequently.

Embodiment 3

[0031] Embodiment three, telescopic anti-retraction device 7 is the second electromagnetic stretcher 75, the second electromagnetic stretcher 75 is arranged on the front end of the main piston rod 6, the first card 76 is installed on the main piston rod 6, and the second electromagnetic stretcher 75 is installed At the rear of the first card 76, when the main piston rod 6 is pushed forward for the first time, the second electromagnetic retractor 75 is activated, and the electromagnetic piston rod 77 is stretched out to block the rear end surface of the first card 76 to prevent the main piston rod from 6 retreats, after finishing production, electromagnetic piston rod 77 retracts, and then main piston rod 6 also retracts.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com