Intelligent wax printing cloth stacker with adjusting function

A stacker and adjustment technology, which is applied in the stacking, transportation and packaging of objects, can solve the problems of high friction between the cloth and the stacker, loose stacking of the cloth, and difficulty in unloading, so as to facilitate automatic adjustment, reset and stacking. The effect of leveling, avoiding tilting or shaking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

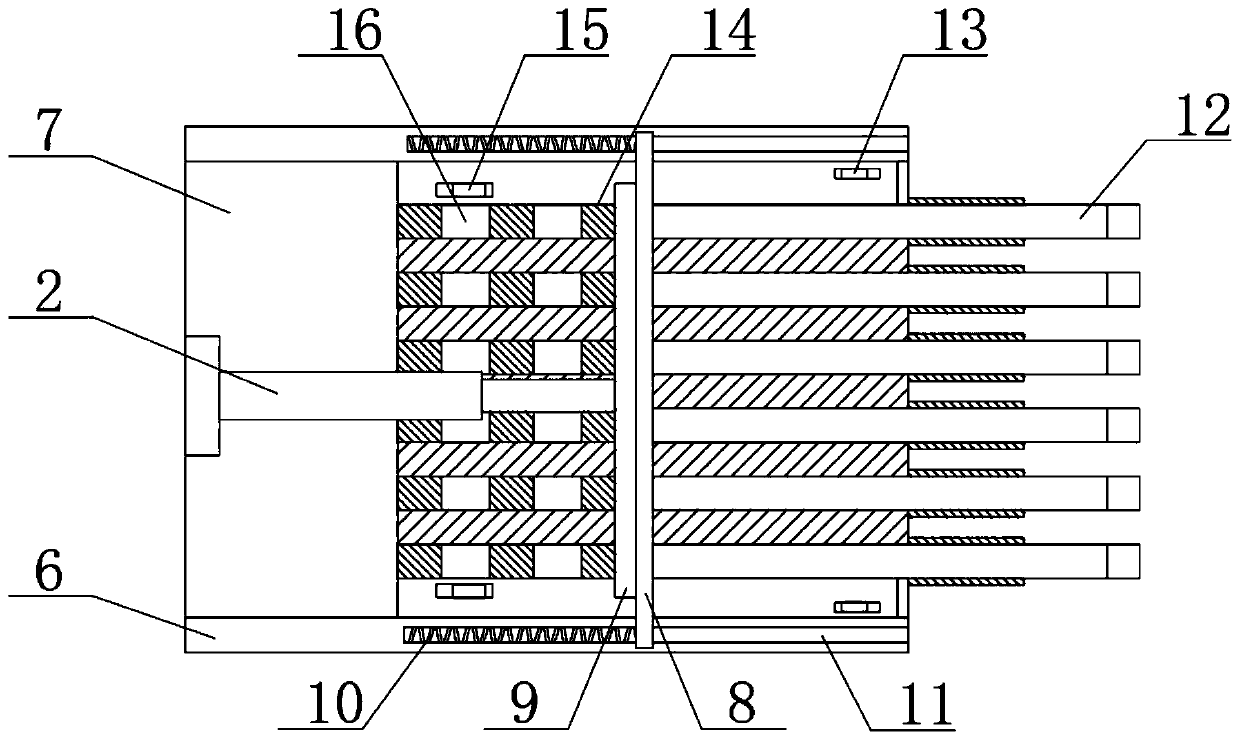

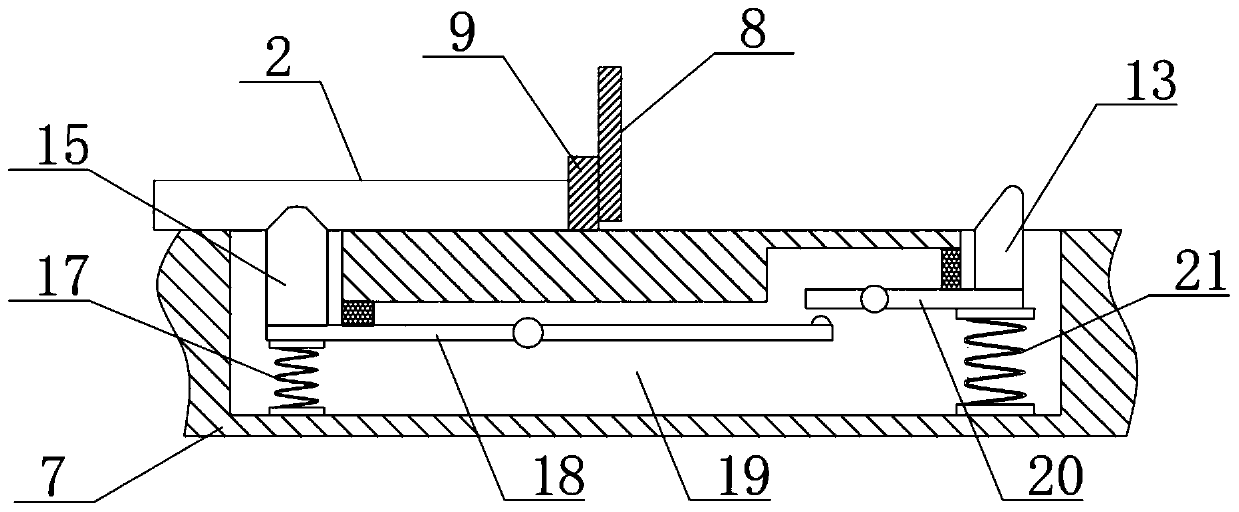

[0023] see figure 1 , figure 2 , image 3 , Figure 4 with Figure 5 , the present invention provides a technical solution: an intelligent batik cloth stacker with adjustment, comprising a stacker bracket 1, a bottom plate 3, a moving wheel 4 and a loading plate 7, and the stacker bracket 1 is arranged on two sides of the upper end surface of the bottom plate 3 side, the moving wheels 4 are arranged on the four corners of the lower end surface of the bottom plate 3, the loading plate 7 is arranged between the two stacker brackets 1, and the electric telescopic arm 2 is arranged on one side of the upper end surface of the object loading plate 7, and the end of the electric telescopic arm 2 The fixed part is provided with a fixed plate 9, and the upper end surface of the loading plate 7 is provided with grooves 14, and there are six grooves 14 evenly distributed, and a sliding rod 12 is embedded in the groove 14, and the upper surface of the embedded end of the sliding rod 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com