Optical lens detection device and method

A technology of optical lenses and testing equipment, which is applied in the direction of mechanical thickness measurement, etc., can solve the problems of optical lens damage detection accuracy, etc., and achieve the effects of avoiding optical lens damage, accurate and effective detection results, and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

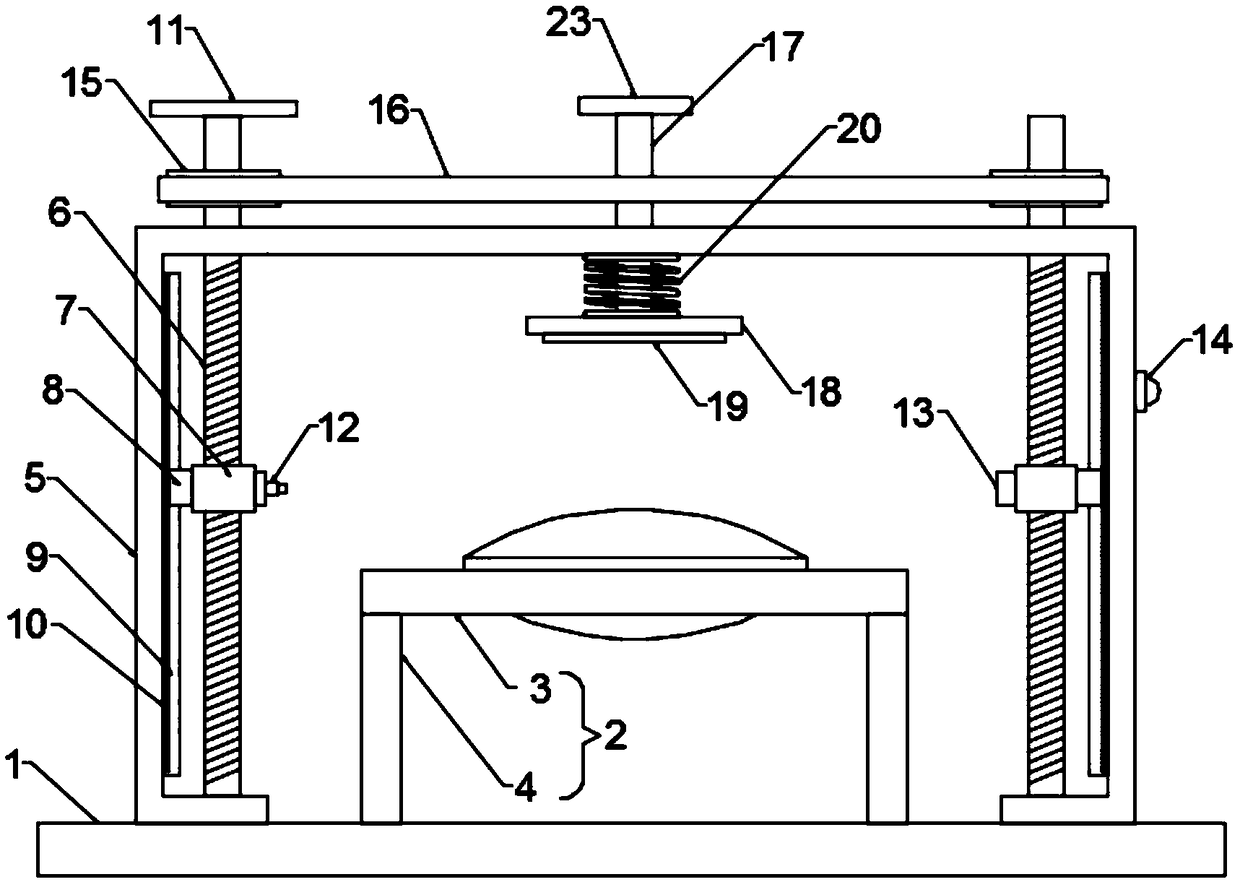

Embodiment 1

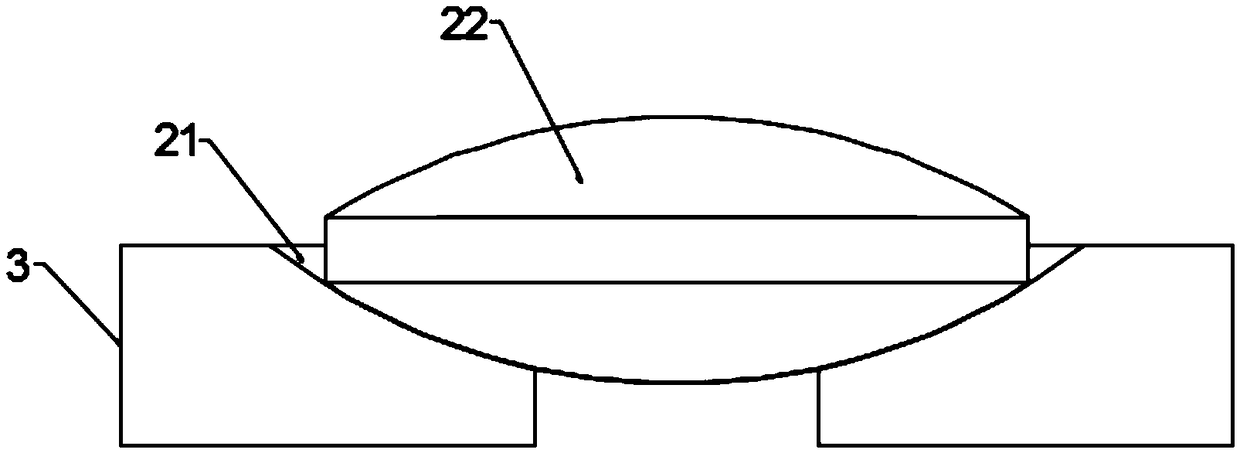

[0023] see figure 1 and 2 , in an embodiment of the present invention, an optical lens inspection device includes a base substrate 1, a placement platform 2 and a mounting rod frame 5, and the placement platform 2 and the mounting rod frame 5 are fixedly installed on the upper end surface of the base substrate 1, so The placement platform 2 is located inside the installation pole frame 5, the placement platform 2 includes two symmetrical decks 3 and a support pole 4 for supporting the deck 3, the lower end of the support pole 4 is fixed on the upper end surface of the base substrate 1 The opposite sides of the upper ends of the two platens 3 are provided with arc-shaped placement grooves 21, and a bracket is formed between the two placement grooves 21, and optical lenses soaked in black ink and dried all over the body are placed in the brackets 22. The installation rod frame 5 is provided with two symmetrical lifting screw rods 6, the axes of the two lifting screw rods 6 are ...

Embodiment 2

[0026] The difference between this embodiment of the present invention and Embodiment 1 is that: the upper end of the installation rod frame 5 is also provided with a pressing mechanism, the pressing mechanism is located directly above the placement platform 2, and the pressing mechanism includes a rod that runs through the upper end of the installation rod frame 5 wall and the guide rod 17 that slides and fits with it, the bottom end of the guide rod 17 is provided with a pressure plate 18, the upper end surface of the pressure plate 18 is connected to the wall of the rod support 5 by the spring 20, and the lower end surface of the pressure plate 18 is provided with a protective pad 19 to avoid To cause damage to the optical lens 22, the top of the guide rod 17 is provided with a pressing plate 23, and the setting of the pressing mechanism can make the optical lens 22 be pressed before detection to ensure its horizontal placement.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com