Carbon/oil/gas co-production integrated device and method

An integrated, carbonization technology, applied in chemical instruments and methods, inorganic chemistry, carbon compounds, etc., can solve the problems of insufficient utilization of waste heat, poor environmental protection, cumbersome system, etc., and achieve the effect of improving the level of automation, reasonable layout, and improving thermal efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

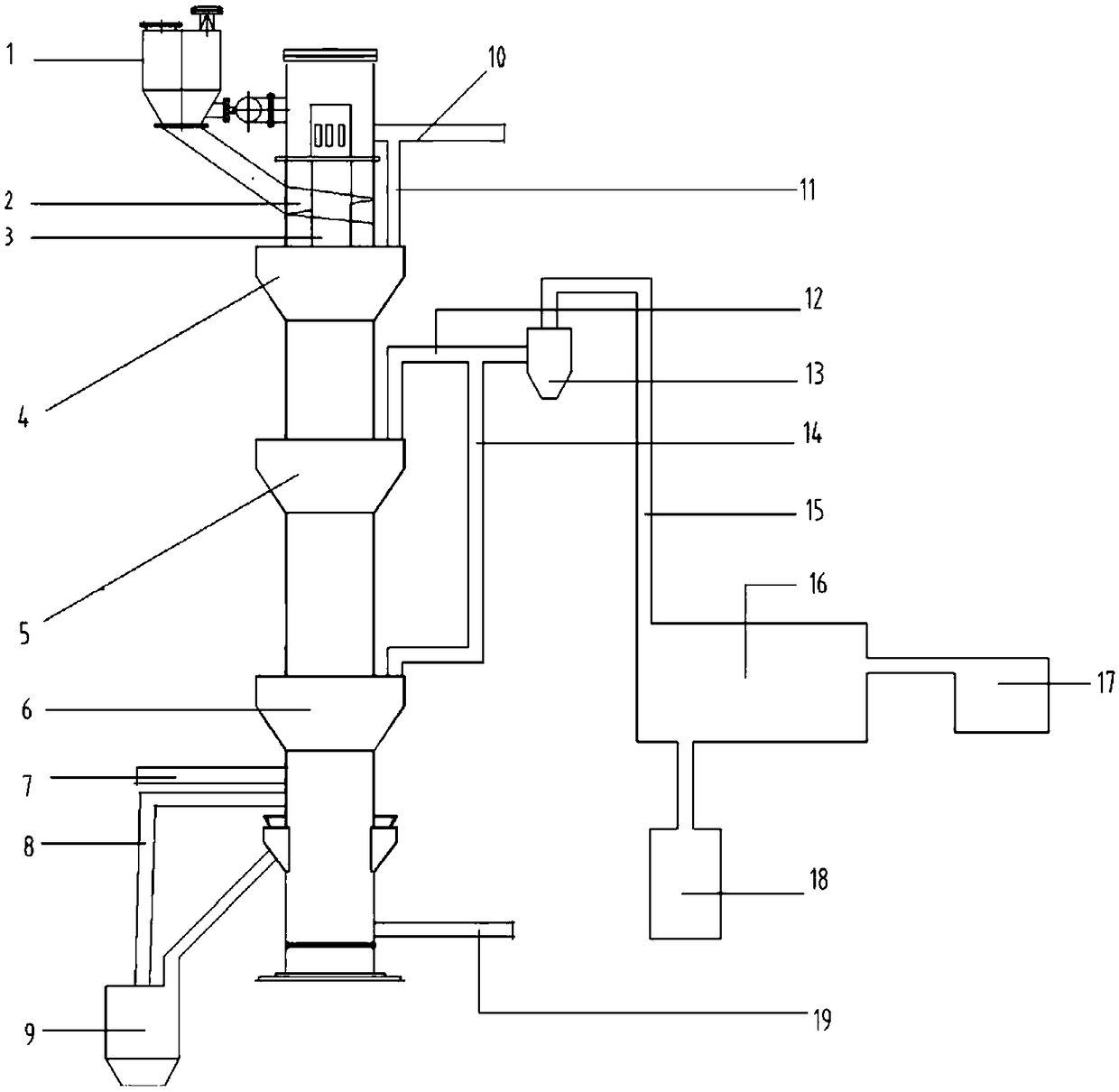

[0052] An integrated device for cogeneration of carbon / oil / gas, such as figure 1 As shown, the device mainly includes a feeder 1, a screw conveyor 2, a flue gas channel 3, a drying section air chamber 4, a pyrolysis section air chamber 5, an activation section air chamber 6, an activation gas inlet 7, and a cooling water vapor pipeline 8. Discharge sealing tank 9, flue gas outlet pipe 10, pyrolysis gas channel 11 in the drying section, pyrolysis gas channel 12 in the pyrolysis section, cyclone separator 13, pyrolysis gas channel 14 in the activation section, pyrolysis gas channel 15, Multi-stage condensing device 16, gas cabinet 17, liquid collector 18, high temperature flue gas channel inlet 19.

[0053] The device is integrated, the center is the flue gas channel 3, the screw conveyor 2 surrounds the flue gas channel 3, the feeder 1 is connected to the inlet of the screw conveyor 2, and the screw conveyor 2 is divided into a drying section, a pyrolysis section, and an activa...

Embodiment 2

[0060] The device described in Example 1 was used to realize biomass pyrolysis polygeneration.

[0061] Step 1, sending the biomass pellets (moisture content is 15%) into the screw conveyor 2 through the feeder 1, and the feed rate is 500kg / h;

[0062] Step 2. Control the reaction temperature of the drying furnace to be 200° C., and the solid phase residence time to be 20 minutes. The dried material is conveyed into the pyrolysis section through screw conveying, and the feed rate is about 400 kg / h (moisture content is 5%);

[0063] Step 3. Control the pyrolysis reaction temperature to 500°C. The high-temperature pyrolysis gas phase product is passed into a three-stage condenser. After condensation, a liquid product and a non-condensable combustible gas are obtained. The yields are 160kg / h and 80kg / h respectively. The semi-coke is transported downwards by spiral and enters the activation section, and the feed rate is 160kg / h;

[0064]Step 4. Control the activation reaction tem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com