Preparation method of low-hardness high-volume resistance rubber water cutting strips

A rubber-water, high-volume technology, applied in rubber insulators, devices for applying liquid to surfaces, coatings, etc., can solve problems such as increased manufacturing costs, corrosion of body sheet metal, and poor anti-corrosion effect, and achieves good processability. , good performance, good reinforcement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

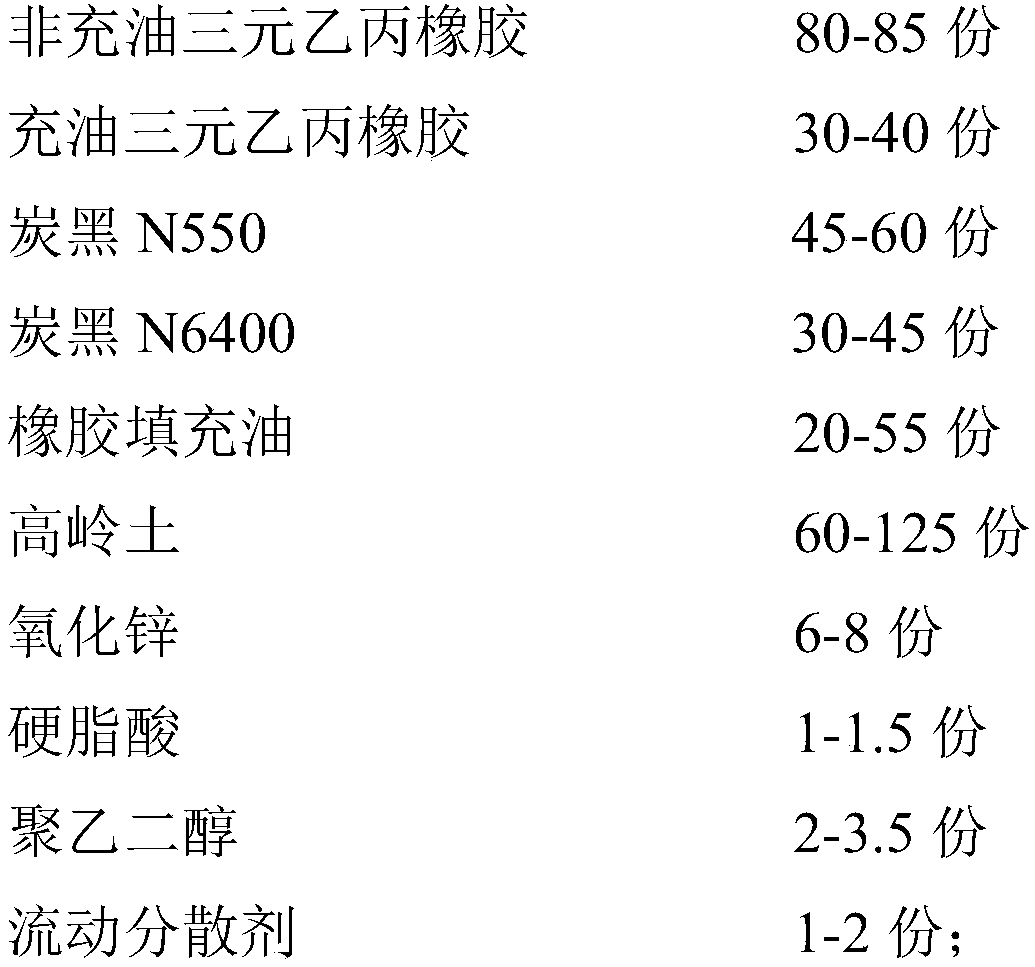

Method used

Image

Examples

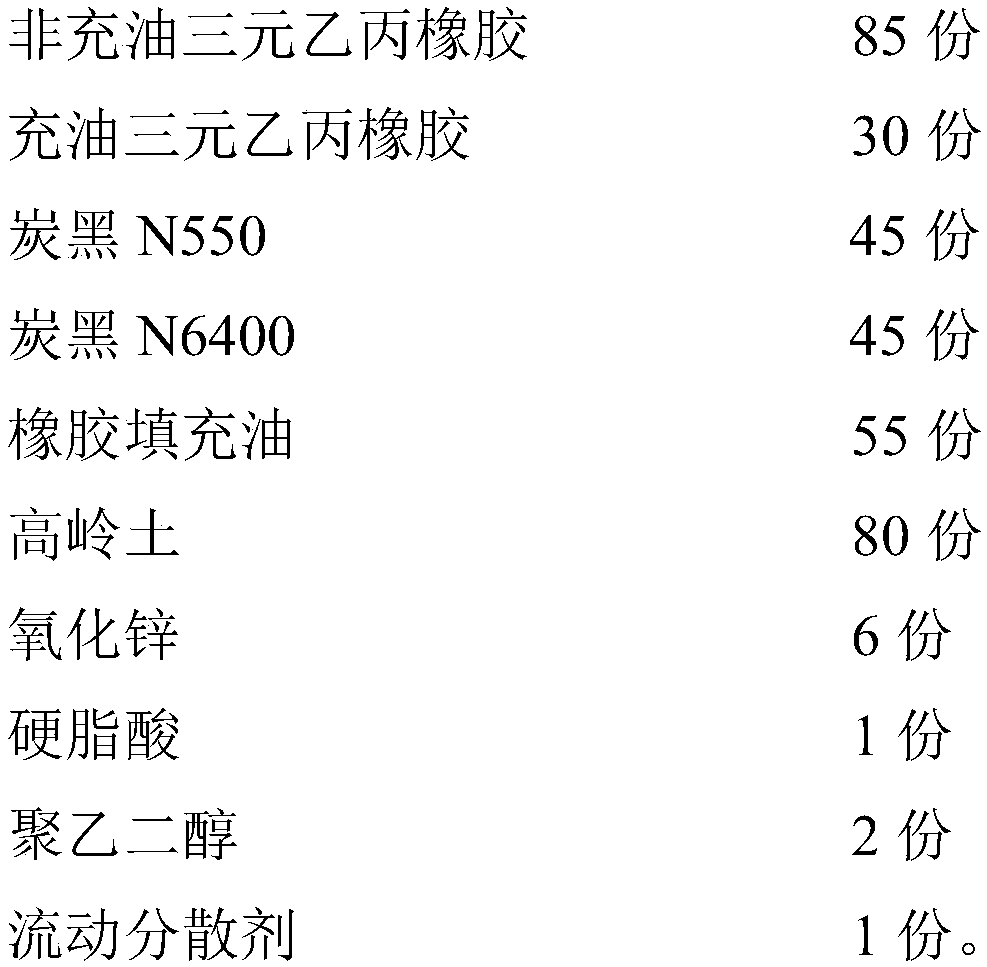

Embodiment 1

[0061] Embodiment 1: The preparation method of a kind of low hardness high volume resistance rubber water-cut strip provided by the present invention comprises the following steps:

[0062] 1) Raw rubber mastication: The raw rubber is masticated on a pressurized internal mixer, the mastication time is 60s, and the mastication temperature is 60°C;

[0063] 2) One-stage rubber mixing: add one-stage rubber formula to the masticated raw rubber for mixing; the mixing process of the internal mixer is to pressurize and banbury for 4 minutes until the temperature reaches 155°C;

[0064] 3) Thinning of a section of glue: transport the mixed section of glue to the first open mill, and carry out thinning on the open mill for 2 minutes. After the thinning is completed, the film is sliced, cooled, and conveyed;

[0065] 4) Second-stage rubber refining: the first-stage rubber after thinning is milled on the second mill, and the raw materials of the second-stage rubber formula are mixed at t...

Embodiment 2

[0072] Embodiment 2: The preparation method of a kind of low hardness high volume resistance rubber water-cut strip provided by the present invention comprises the following steps:

[0073] 1) Raw rubber mastication: masticate the raw rubber on a pressurized internal mixer, the mastication time is 60s, and the mastication temperature is 80°C;

[0074] 2) One-stage rubber mixing: add one-stage rubber formula to the masticated raw rubber for mixing; the mixing process of the internal mixer is to pressurize and banbury for 5 minutes until the temperature reaches 160°C;

[0075] 3) Thinning of a section of glue: transport the mixed section of glue to the first open mill, and carry out thinning on the open mill for 3 minutes. After the thinning is completed, the film is sliced, cooled, and conveyed;

[0076] 4) Second-stage rubber milling: The first-stage rubber after thinning is milled on the second mill, and the raw materials of the second-stage rubber formula are mixed at the sa...

Embodiment 3

[0083] Embodiment 3: The preparation method of a kind of low hardness high volume resistance rubber water-cut strip provided by the present invention comprises the following steps:

[0084] 1) Raw rubber mastication: The raw rubber is masticated on a pressurized internal mixer, the mastication time is 60s, and the mastication temperature is 60°C;

[0085] 2) One-stage rubber mixing: add one-stage rubber formula to the masticated raw rubber for mixing; the mixing process of the internal mixer is to pressurize and banbury for 6 minutes until the temperature reaches 165°C;

[0086] 3) Thinning of a section of glue: transport the mixed section of rubber to the first open mill, and carry out thinning on the open mill for 4 minutes. After the thinning is completed, the film is sliced, cooled, and conveyed;

[0087] 4) Second-stage rubber milling: The first-stage rubber after thinning is milled on the second mill, and the raw materials of the second-stage rubber formula are mixed at ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com