Sewage treatment system for metal surface treatment wastewater and control method

A metal surface treatment and sewage treatment system technology, applied in water/sewage treatment, metallurgical wastewater treatment, oxidized water/sewage treatment, etc., can solve the problems of poor treatment effect, low treatment efficiency, long process flow, etc., and achieve full promotion Mixing, good treatment effect, simple treatment process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

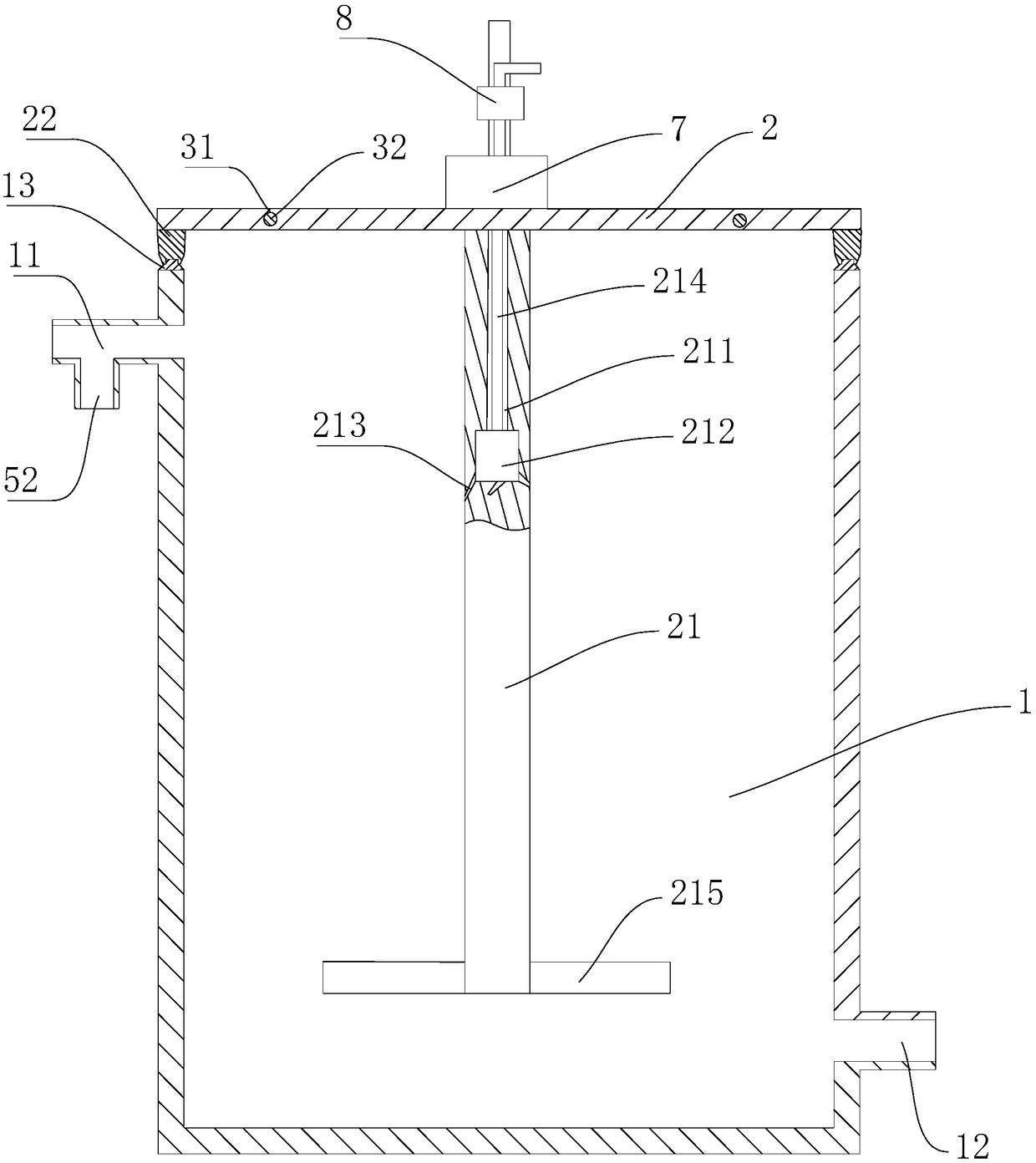

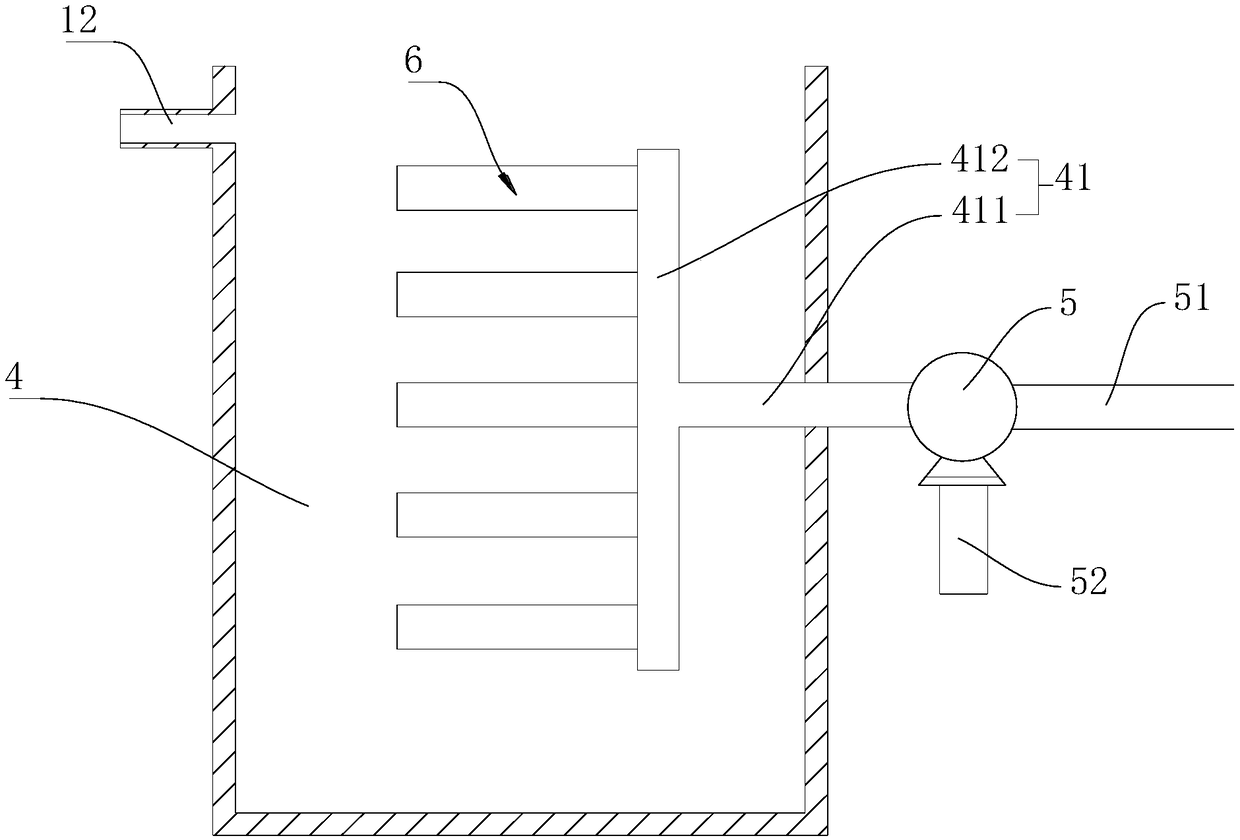

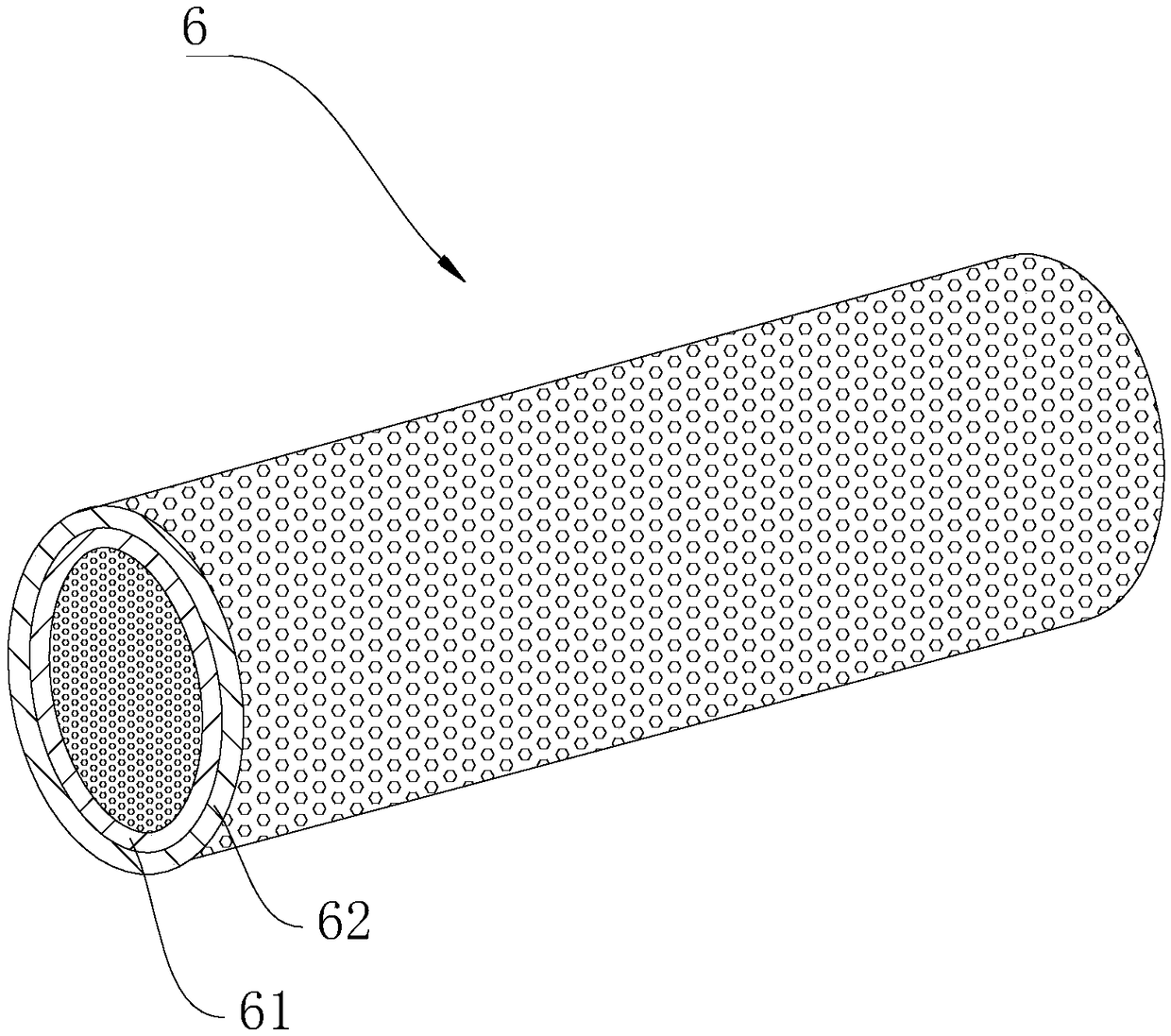

[0044] Embodiment 1: a kind of sewage treatment system of metal surface treatment waste water, as figure 1 As shown, the pretreatment device is used for preliminary treatment of metal surface treatment wastewater; the membrane treatment device is used for reprocessing the pretreated metal surface treatment wastewater.

[0045] Such as figure 1 As shown, the pretreatment device includes a pretreatment pool 1, and the length direction of the pretreatment pool 1 is figure 1 In the direction of the inside and outside of the paper, the upper side of the pretreatment tank 1 is provided with a water inlet pipe 11 for passing in waste water, and the lower end of the pretreatment tank 1 is provided with an outlet pipe 12, which communicates with the membrane treatment device. The upper end of the pretreatment tank 1 is provided with an installation part 2, and the installation part 2 moves along the length direction of the pretreatment tank 1 under the action of a power source (not sh...

Embodiment 2

[0053] Embodiment 2: A method for controlling the sewage treatment system of metal surface treatment wastewater, used to control the sewage treatment system of metal surface treatment wastewater in the above embodiment, such as Figure 1 to Figure 3 shown, including the following steps:

[0054] S1: Pretreatment: pretreatment of metal surface treatment wastewater, the treatment time is 2 hours;

[0055] (1) Pass metal surface treatment wastewater into the pretreatment tank 1 and stir;

[0056] (2) Feed the wastewater treatment liquid into the feed pipe 211, the waste water treatment liquid enters the cavity 212 through the feed pipe 211, and is sprayed into the pretreatment tank 1 by the drainage groove 213; at the same time, the stirring shaft 21 moves along the pretreatment tank 1 move in the length direction;

[0057] (3) After the wastewater treatment liquid is sprayed, gas is introduced into the air inlet pipe 214, the gas enters the cavity 212 through the air inlet pip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com