Manufacturing method of novel cutting die plywood

A production method and technology of plywood, which is applied in the jointing of wooden veneers, manufacturing tools, forming/shaping machines, etc., can solve the problems of uneven gap size between knives, unstable laser output power, time-consuming and labor-intensive installation process, etc. Achieve the effects of improving processing quality, reducing debugging time on the machine, and facilitating tool installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] A kind of manufacture method of novel die-cutting plywood, comprises the steps:

[0024] The first step, preparation of birch plywood

[0025] (1.1) Select birch as logs;

[0026] (1.2) Carry out rotary cutting processing on the above logs to make several birch veneers 1 with matching specifications;

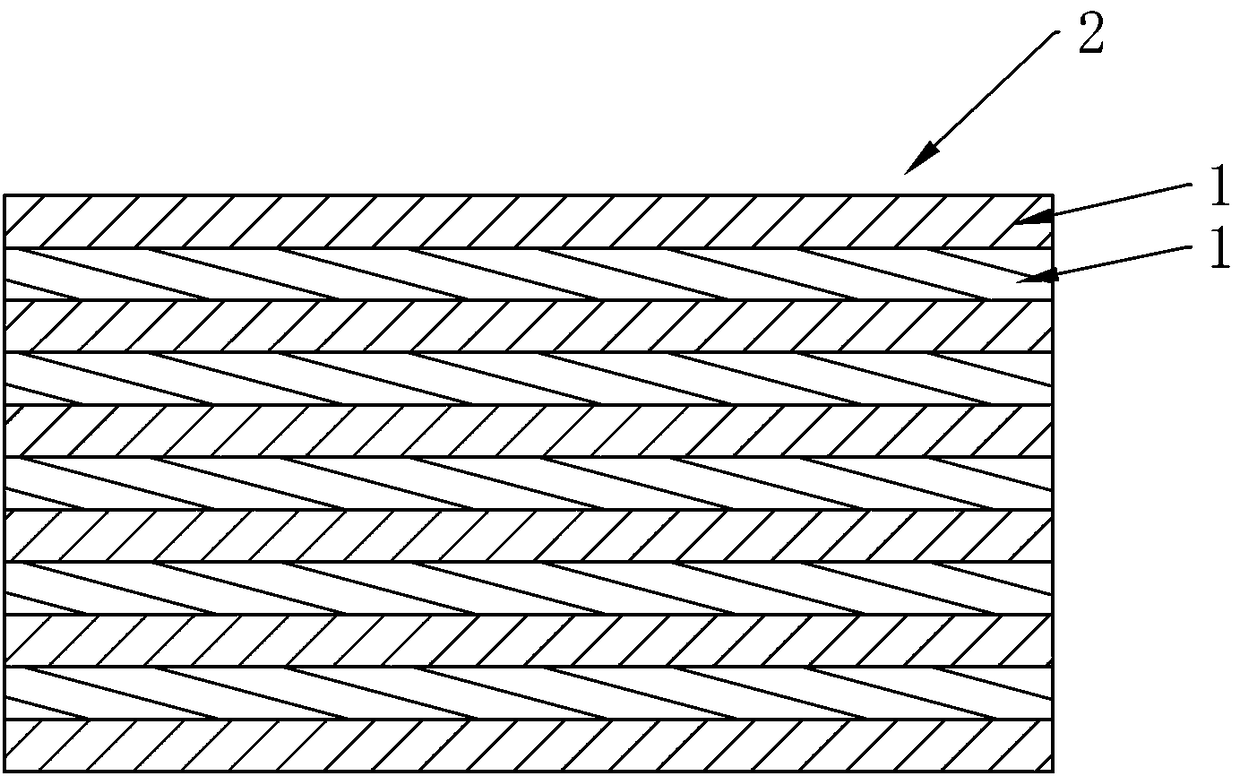

[0027] (1.3) The above-mentioned several pieces of birch veneer 1 are stacked and glued together from bottom to top through glue, and the lines between any two adjacent birch veneers 1 are perpendicular to each other to form a multi-layer structure. Structural birch plywood 2, see figure 1 ;

[0028] The second step, cold forming

[0029] (2.1) Select several pieces of birch plywood 2;

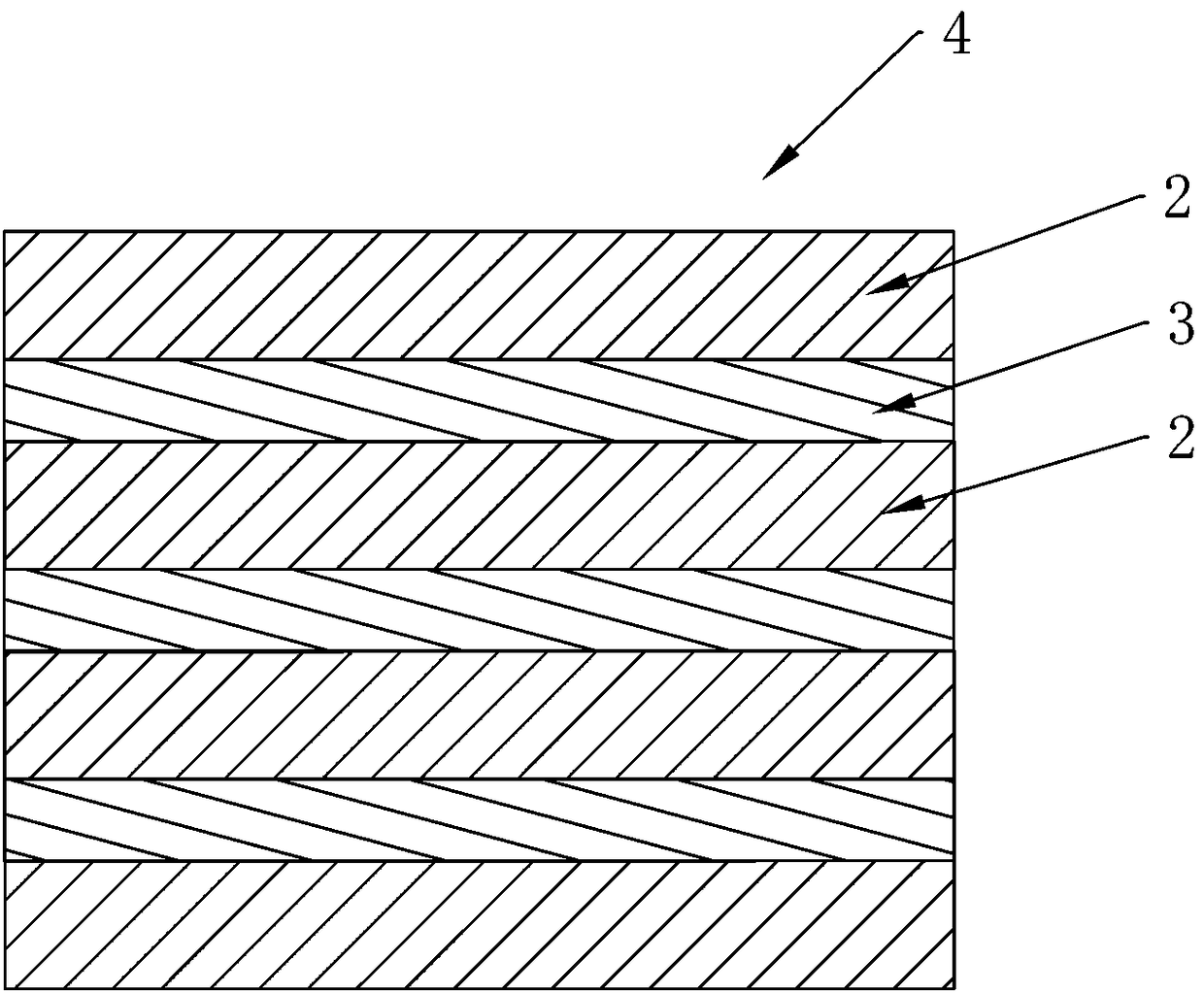

[0030] (2.2) Use glue to stack the above-mentioned several pieces of birch plywood 2 together sequentially from bottom to top, and fill a piece of planed birch plywood 3 between any two adjacent pieces of birch plywood 2, Birch composite board 4 is obtained;

[0031] (2.3) The birc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com