Dust collection device on laser cutting machine

A technology of laser cutting machine and dust collector, applied in laser welding equipment, welding equipment, metal processing equipment and other directions, can solve the problems of respiratory tract infection, endanger human health, high energy consumption, etc., and achieve the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

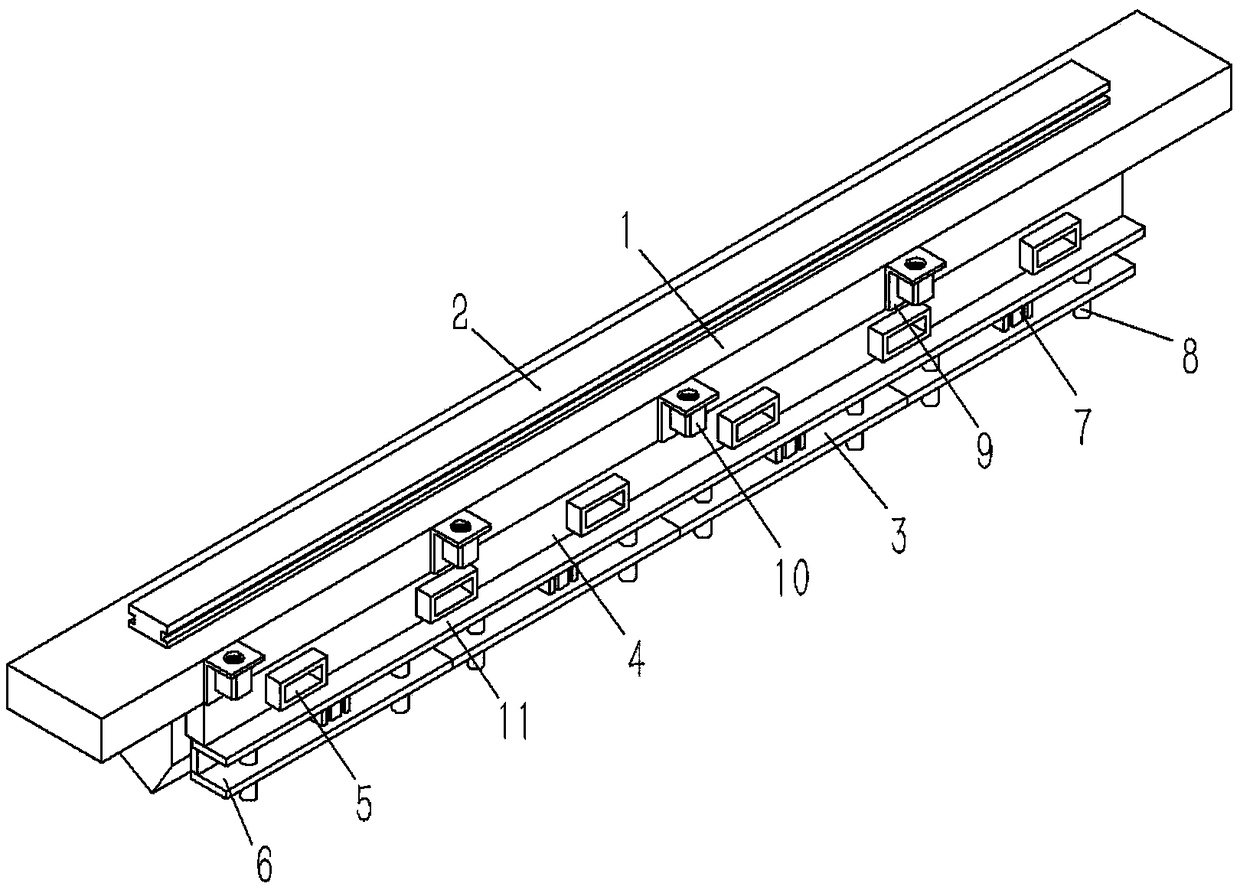

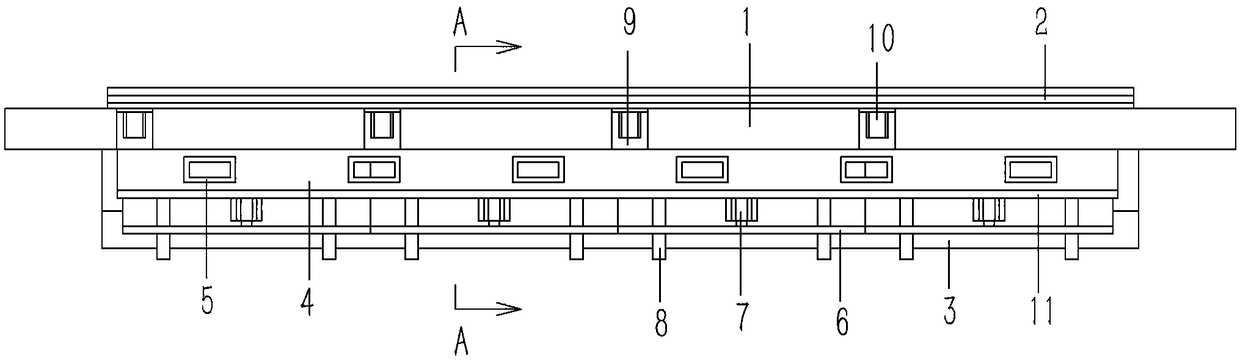

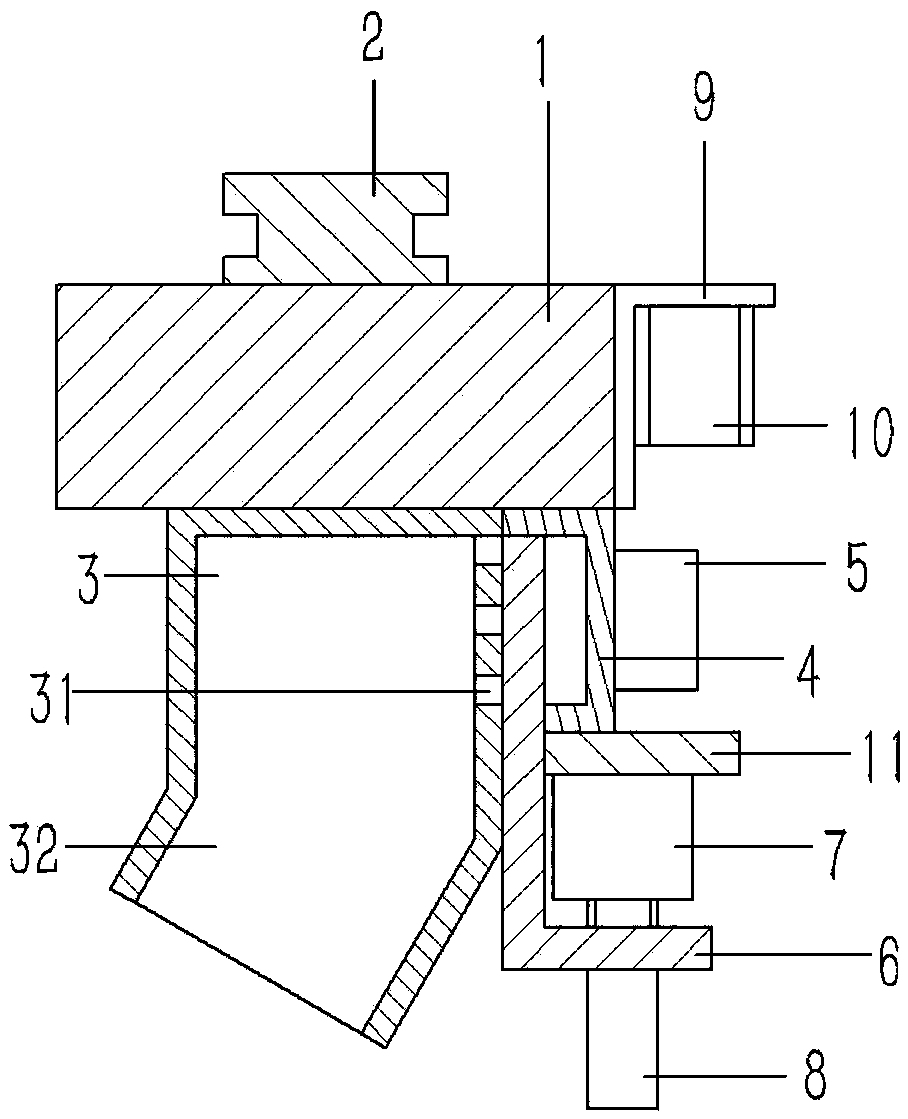

[0016] Example: see Figures 1 to 3 As shown, a dust suction device on a laser cutting machine includes a horizontal feed main beam 1, a horizontal guide rail 2 is fixed on the upper end surface of the feed main beam 1, and a suction suction device fixed on the lower end surface of the feed main beam 1 Dust cover 3, a side wall of the dust collection cover 3 is formed with a number of horizontal dust suction grooves 31, and the outer wall of the dust collection cover 3 is fixed with a dust discharge shell 4 communicating with the dust suction groove 31, and the dust discharge The outer wall of the housing 4 is fixed with a dust discharge pipe 5 communicating with the dust discharge housing 4, and the lower end surface of the dust discharge housing 4 is formed with slots, and several slots are inserted into the slots of the dust discharge housing 4. L-shaped valve plate 6, the valve plate 6 is against the outer wall of the dust collection cover 3 and covers the dust suction gro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com