Exquisite repairing eye cream and preparation method thereof

An eye cream, delicate technology, applied in the field of skin care products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

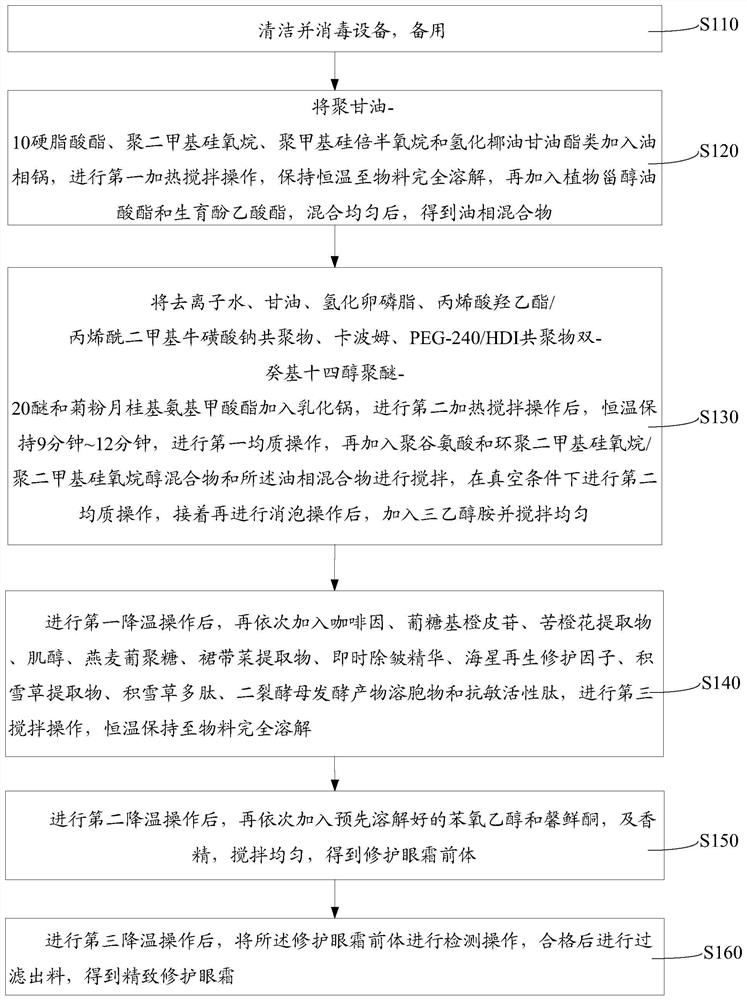

[0080] see figure 1 , the preparation method of the delicate repairing eye cream of an embodiment, comprises the following steps:

[0081] S110. Clean and disinfect the equipment, and set it aside.

[0082] In order to ensure the quality of the prepared refined repairing eye cream and to be free from pollutants, it is first necessary to clean and disinfect the equipment used in the preparation.

[0083] S120. Add polyglyceryl-10 stearate, polydimethylsiloxane, polymethylsilsesquioxane, and hydrogenated cocoglycerides to the oil phase pot, perform the first heating and stirring operation, and keep the constant temperature until The material is completely dissolved, then add phytosterol oleate and tocopheryl acetate, and mix uniformly to obtain an oil phase mixture, wherein the polyglycerol-10 stearate, the polydimethylsiloxane, The mass ratio of the polymethylsilsesquioxane, the hydrogenated cocoglycerides, the phytosterol oleate and the tocopheryl acetate is (0.05-0.8): (0.5...

Embodiment 1

[0096] Clean and sanitize equipment, ready for use;

[0097] Add 0.3kg of polyglycerol-10 stearate, 2.0kg of polydimethylsiloxane, 0.5kg of polymethylsilsesquioxane, and 3.0kg of hydrogenated cocoglycerides into the oil phase pot, and heat at 70°C Under the conditions, carry out the first heating and stirring operation, keep the constant temperature until the material is completely dissolved, then add 0.5 kg of phytosterol oleate and 0.8 kg of tocopheryl acetate, and mix well to obtain the oil phase mixture;

[0098] 59.24kg of deionized water, 10kg of glycerin, 0.3kg of hydrogenated lecithin, 0.8kg of hydroxyethyl acrylate / sodium acryloyldimethyl taurate copolymer, 0.3kg of carbomer, PEG-240 / HDI copolymer bis- Add 0.5kg of decyltetradeceth-20 ether and 0.3kg of inulin lauryl carbamate into the emulsification pot. After the second heating and stirring operation is performed at 80°C, the temperature is maintained for 9 minutes, and the first Homogeneous operation, then add pol...

Embodiment 2

[0103] Clean and sanitize equipment, ready for use;

[0104] Add 0.3kg of polyglycerol-10 stearate, 2.0kg of polydimethylsiloxane, 0.5kg of polymethylsilsesquioxane, and 3.0kg of hydrogenated cocoglycerides into the oil phase pot, and heat at 70°C Under the conditions, carry out the first heating and stirring operation, keep the constant temperature until the material is completely dissolved, then add 0.5 kg of phytosterol oleate and 0.5 kg of tocopheryl acetate, and mix well to obtain the oil phase mixture;

[0105] 58.84kg of deionized water, 10kg of glycerin, 0.3kg of hydrogenated lecithin, 0.8kg of hydroxyethyl acrylate / sodium acryloyldimethyl taurate copolymer, 0.3kg of carbomer, PEG-240 / HDI copolymer bis- Add 0.5kg of decyltetradeceth-20 ether and 0.3kg of inulin lauryl carbamate into the emulsification pot. After the second heating and stirring operation is performed at 80°C, the temperature is maintained for 9 minutes, and the first Homogeneous operation, then add pol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com