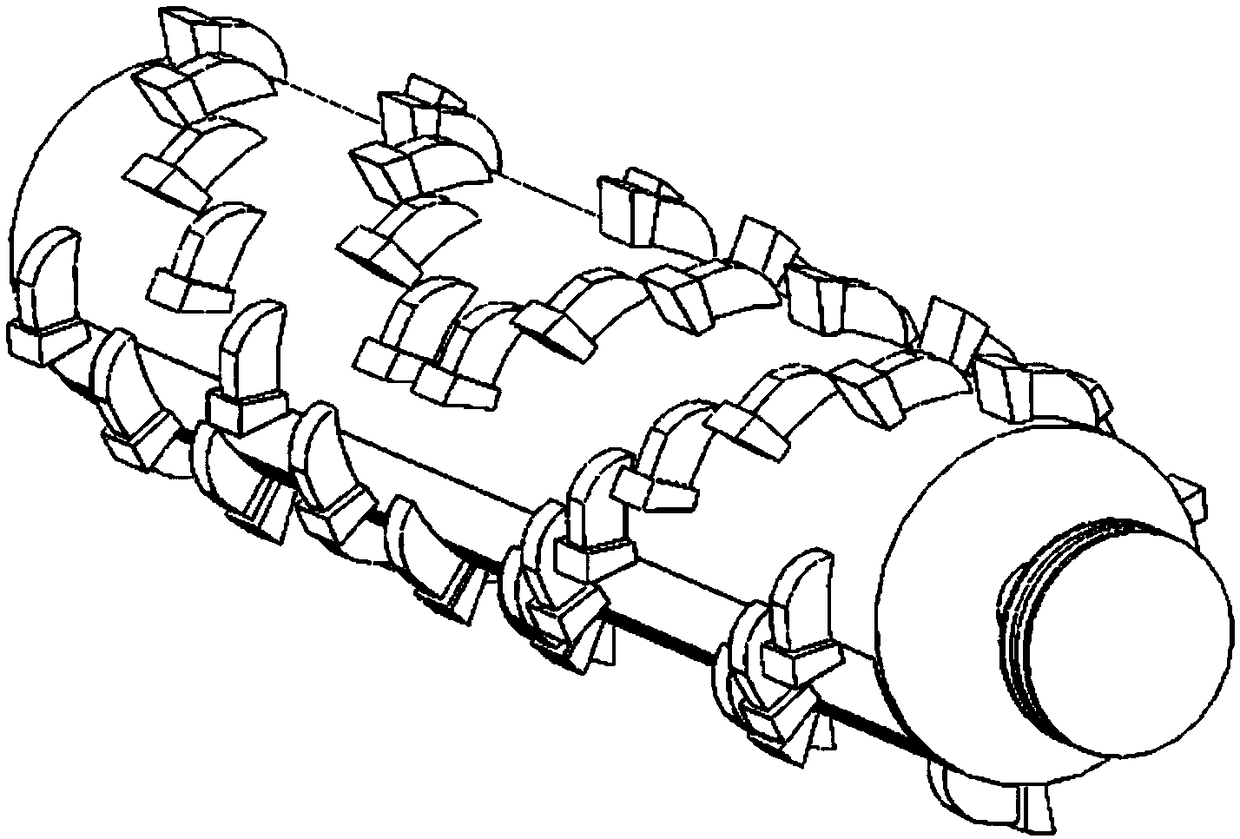

Cutting mechanism of roller-type forest cleaning device

A cutting mechanism, stick-type technology, applied in the direction of cutting tools, cutting equipment, agricultural machinery and implements, etc., can solve the problems of large cutting parts, energy waste, and inability to save fuel, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following is a detailed description of the embodiments of the present invention: this embodiment is implemented on the premise of the technical solution of the present invention, and provides detailed implementation methods and specific operation processes. It should be noted that those skilled in the art can make several modifications and improvements without departing from the concept of the present invention, and these all belong to the protection scope of the present invention.

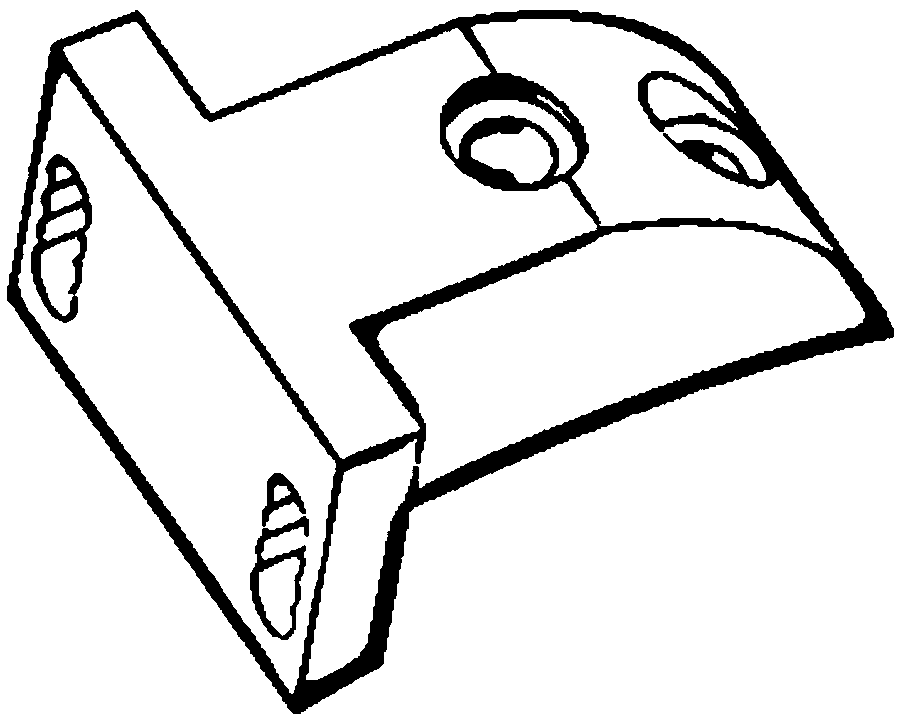

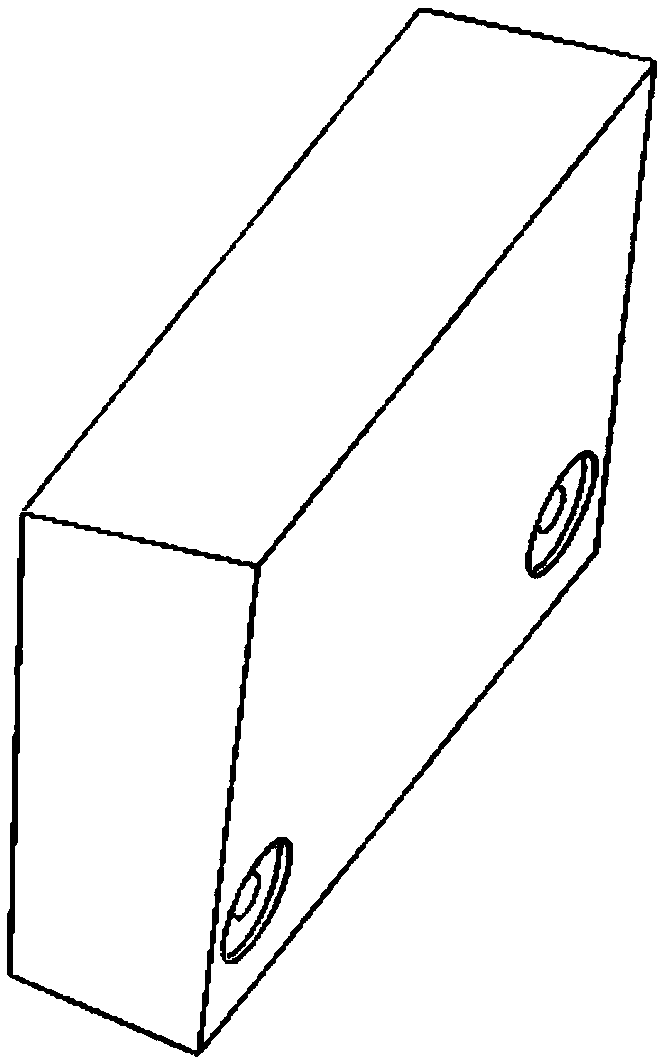

[0024] Such as figure 1 As shown, this embodiment provides a cutting mechanism of a stick-type forest clearing device, which mainly includes three parts: a knife, a knife seat and a knife stick.

[0025] Such as figure 1 As shown, the tool is fixed on the knife seat through bolt connection, and the knife seat is fixed on the knife stick through bolt connection, and is arranged in the shape of "herringbone" on the knife seat.

[0026] When working, the power device has a forward feed m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com