sige/ge/sige double heterojunction laser and its preparation method

A double heterojunction and laser technology, applied in the field of semiconductors, can solve the problems of low luminous efficiency and high threshold current density of lasers, and achieve the effect of reducing process difficulty, reducing threshold current density, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041]Based on the defects of low luminous efficiency and high threshold current density in traditional Ge-based lasers, it is very meaningful to study heterojunction structures based on modified Ge. The technical problem of semiconductor Ge-based laser research is how to obtain low threshold current density and high energy conversion efficiency, while improving beam quality and having good spectral characteristics. With the development and progress of material growth and device preparation process. The performance of semiconductor Ge-based lasers has been continuously improved, and the optoelectronic integration of Ge-based lasers can be realized in the near future. The significance of the research of the present invention is to obtain a novel laser structure based on SiGe / Ge / SiGe double heterojunction. Therefore, it is possible to focus on improving the threshold current density and efficiency and reducing optical loss to design a Ge-based laser with higher performance.

...

Embodiment 2

[0061] In the SiGe / Ge / SiGe double heterojunction laser of this embodiment, the molar composition of Ge in SiGe is 0.5, and the molar composition of Ge in Si is 0.5; that is, the SiGe material in the SiGe / Ge / SiGe double heterojunction laser specifically Si 0.5 G 0.5 . The determination of this component is based on the main part of the device structure, that is, the parameters such as the forbidden band width, thickness and doping concentration of each layer of the SiGe / Ge / SiGe double heterojunction, combined with software simulation analysis, and the results obtained after repeated optimization . Experiments have shown that Si 0.5 G 0.5 The material can optimize the lattice mismatch, refractive index, bandgap, etc. required by the SiGe / Ge / SiGe double heterojunction.

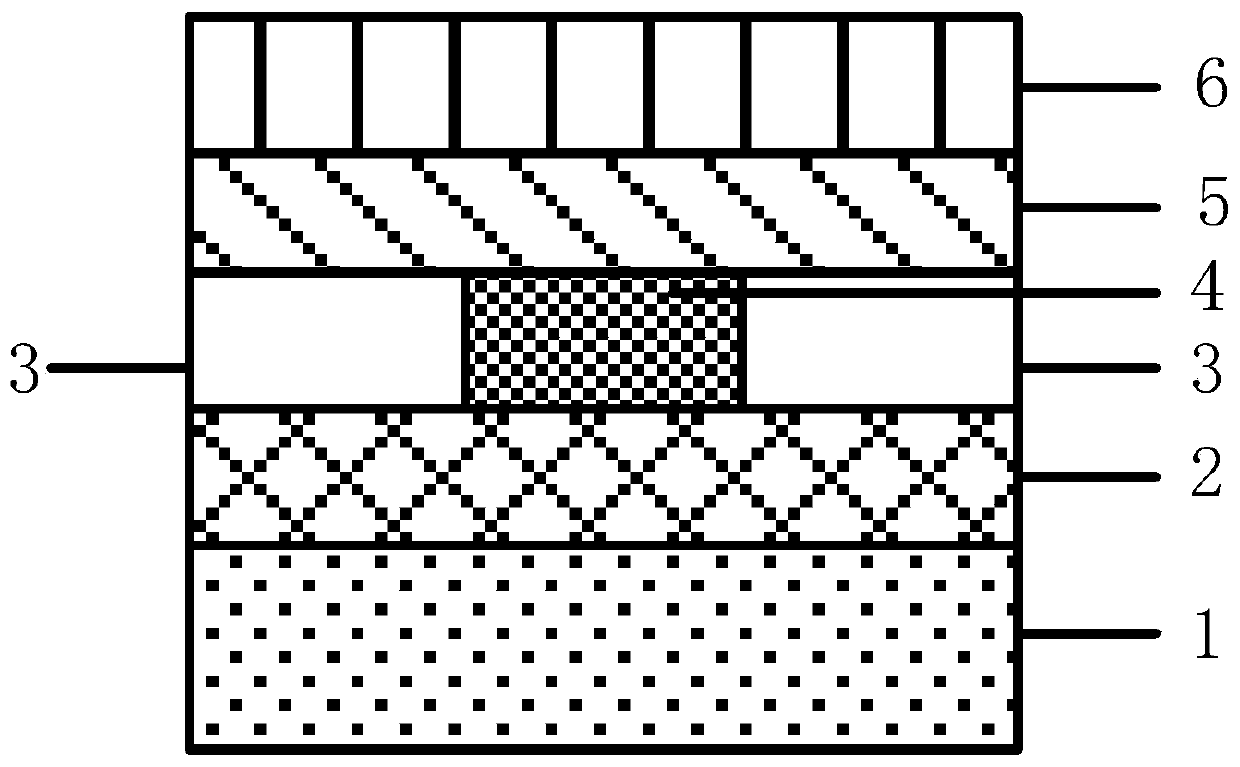

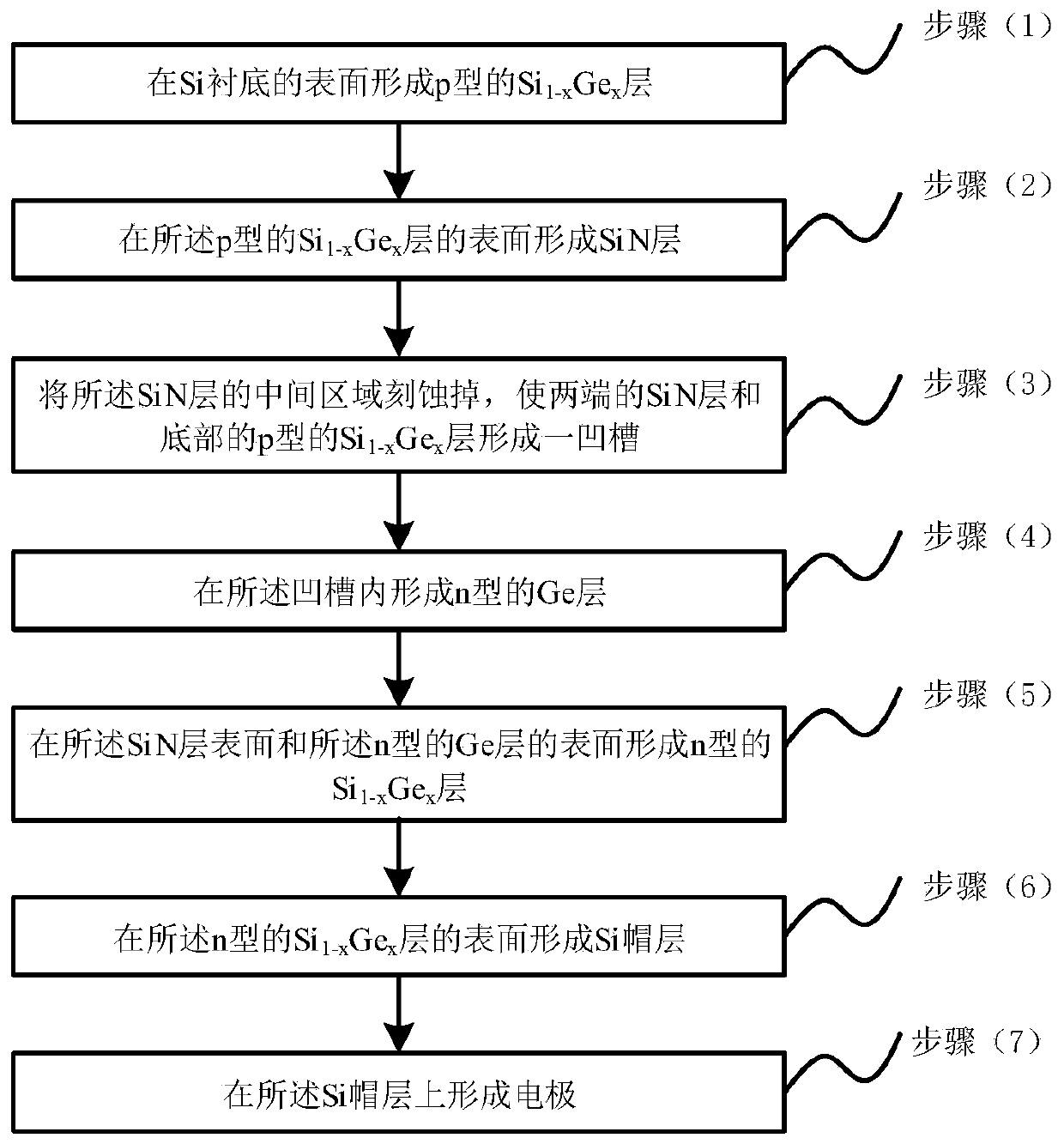

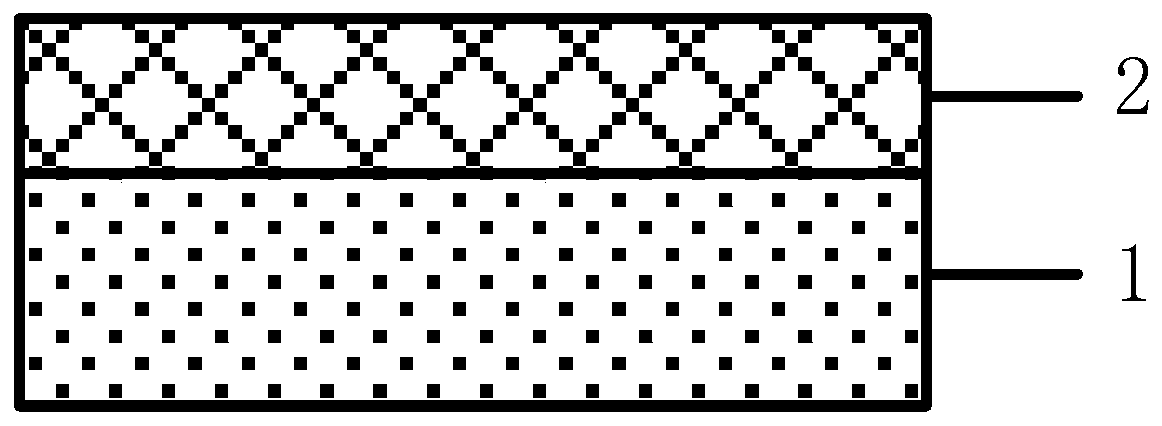

[0062] See 3(a) to 3(f), and figure 1 In this embodiment, on the basis of the above-mentioned embodiments, the preparation method of the SiGe / Ge / SiGe double heterojunction laser and the prepared SiGe / Ge / SiG...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com