Low-loss coaxial cable

A coaxial cable, low-loss technology, applied in the cable field, can solve the problems of deterioration of cable transmission performance, increase cable core resistance, increase contact resistance, etc., to achieve the effect of enhancing strength, protecting normal use, and reducing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

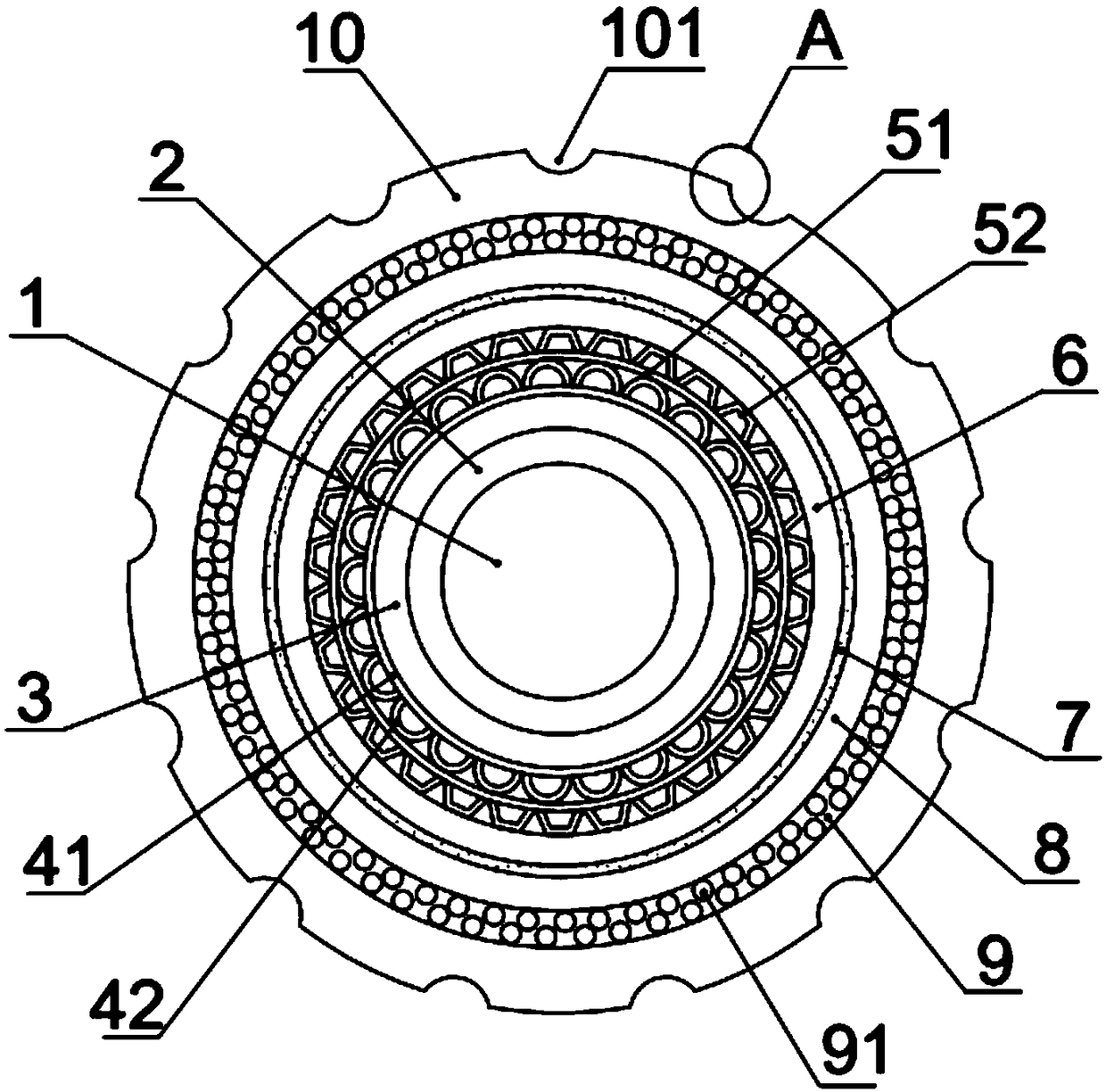

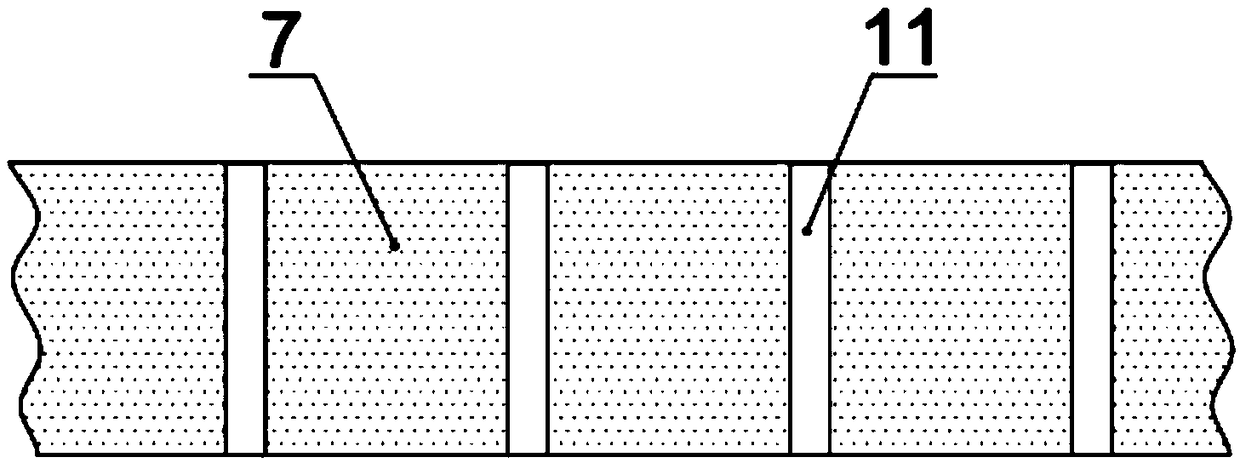

[0027] like Figure 1 to Figure 4 As shown, the low-loss coaxial cable includes an inner conductor, and the outside of the inner conductor is covered with an insulating layer 2, an outer conductor layer 3, a dielectric layer, a shielding layer 6, an inner sheath 8, a water-absorbing layer 9 and an outer sheath in turn. Set of 10.

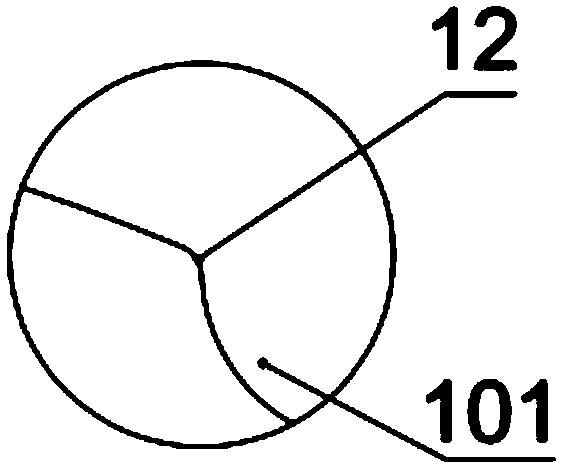

[0028] The outer surface of the outer sheath 10 is provided with several axial grooves 101 extending in the axial direction, and the axial grooves 101 are connected with a circumferential groove 102 around the outer sheath 10. When encountering rainy weather, the axial grooves 101 and The circumferential groove 102 has a drainage effect, and the rainwater will flow to the ground along the axial groove 101 and the circumferential groove 102 . The axial grooves 101 are evenly distributed in the circumferential direction of the outer sheath 10, the cross-sectional shape of the axial grooves 101 is semicircular, and the cross-sectional shape of the joi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com